37

d

&

ri

NOVEMBER-DECEMBER 2014

EQUIPMENT

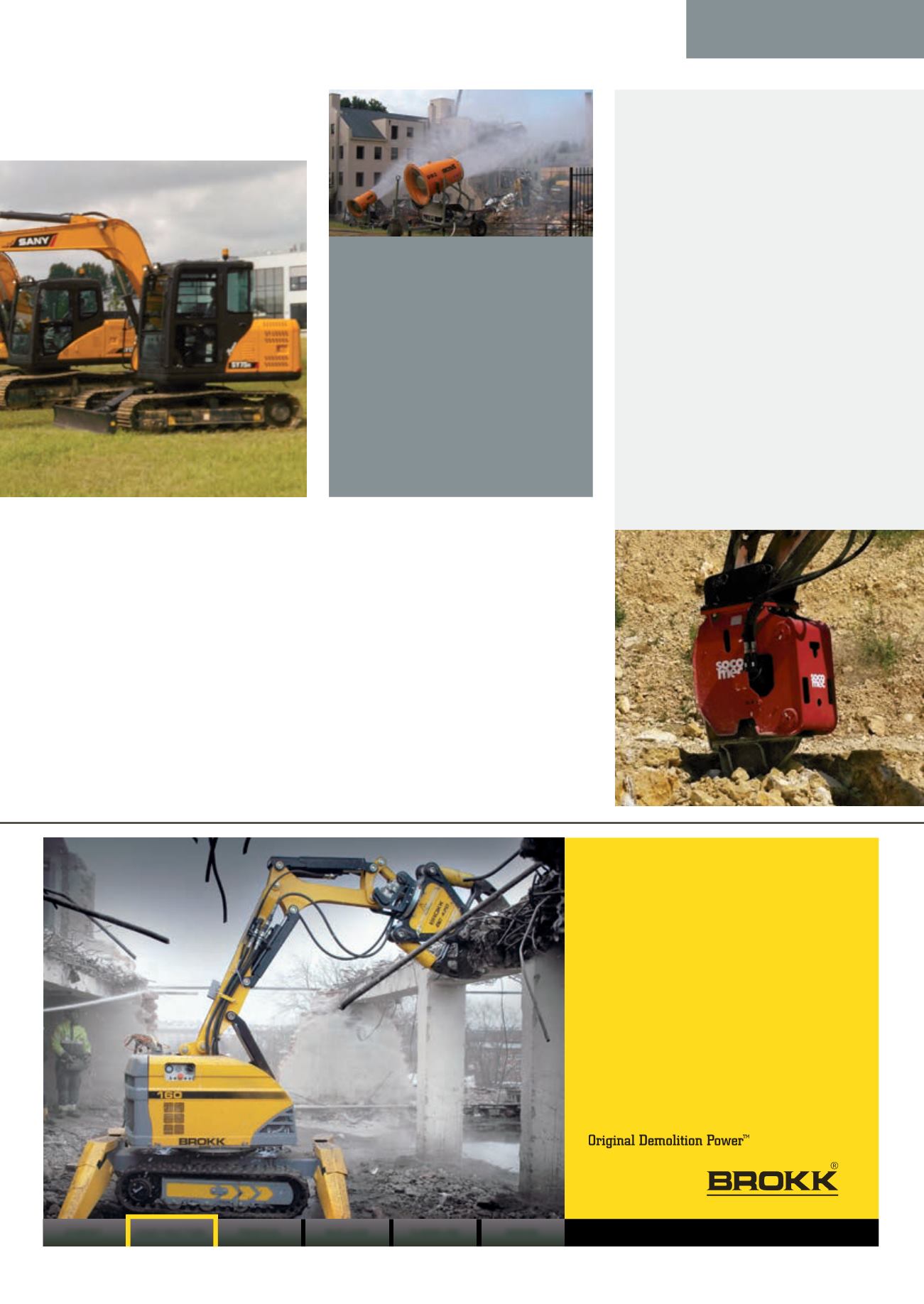

Ripping in

Socomec, based inMedesano, Italy, used

the Samoter exhibition to introduce a

new threemodel range of vibrating ripper

attachments for mining, quarrying and

demolition applications. The three new

attachments - the RVS 2100, RVS 3300

and RVS 4500 – cover carriers from 21

up to 60 tonne. According to the company,

they are the result of an extended

development and testing programme and

deliver excellent performance when working

withmedium-low hardnessmaterials, such

as gypsum and limestone, exceeding that

of hydraulic breakers of a similar category.

Completely fabricated from high

strength steel, the simple structure and

compact design minimises servicing

requirements, with the tooth - the only

wear component - being easy to replace,

says the company. Examples of the new

tools are nowworking on a number of

challenging jobsites and quarries around

the world.

BrokkAB

|

Box 730, 931 27 Skellefteå

|

CEMENT

PROCESS

NUCLEAR

TUNNELING

MINING

CONSTRUCTION

UNBEATABLE

PERFORMANCE

Nobody beatsBrokk

when it comes to demolition

at reconstructions or renovations of residential,

commercial or industrial facilities. This remote-

controlled, electric powerhouse combines

impressive hitting power with an outstanding

reach, while the operator works at a safe distance

from vibrations and falling debris.

Brokk is so light that it canwork even onweak

floors. So clever that it can take the stairs (or the

elevator) between floors. So effective that you see

the difference on the bottom line. In each project.

growth

Youhave tohave ahigh stockof spareparts.”

He admitted that some customersmight

have aperception thatChinesemachinery

suggested inferior quality, cheapmachines

andno aftersales. Bart said the company

was communicating themessageofGerman

quality, coveringmanufacturing, distribution,

R&D and thepeoplewho are employedby

the company. “Wehave industry experts

and theGermanname stands for quality.

Communicating this gives confidence to

customers.”

For themost part, Sanyworkswith

exclusive, establishednational dealers. “Sany

correctlywaits for the right partner,” saidBart.

“Nowwe covermost of the targetmarket.”

For excavators, he said the timewas right

to expanddistribution inEurope. “We are

embarkingonworkingwith exclusivedealers.

Wehave confidence in thequality.Wehave

no fears over thedurabilityor reliabilityof

theproduct.Wehaveno issueswith that. It’s

the samewith components –weuseproven

components.”

The five excavators currently inEurope are

trackedmodels, with twomoreduenext year.

Bart said, “Thebasemachine is there, but the

next generationmaybemore aesthetic– for

examplemaking the cabmoreEuropean.”

At the same time, Sanyhas alsobeen

workingon awheeled excavator concept in

China.Decroos said this couldbe introduced

toEurope at somepoint in the future. There

is a full rangeof excavators inChina, andhe

saidhe expected there tobe 10 to12models

inEuropewithin thenext 18months.

■

Dust Control Technology’s DustBoss dust

suppressionmachines have gained Underwriters

Laboratories (UL) and Canadian Standards

Association certification (CSA) certification in the

USA and Canada. Threemachines have covered

- the DustBoss DB-30, DB-45 and DB-60 direct

drive designs thatwent through a lengthy testing

programme. Dust Control believes that these are

the first atomisedmisting units to gain this level of

accreditation. Using standards developed by UL and

CSA, the evaluation and certification processwas

conducted by SGS, a globally respectedNationally

Recognised Testing Laboratory (NRTL) accredited

by the USOccupational Safety andHealth

Administration (OSHA).