36

NOVEMBER-DECEMBER2014

d

&

ri

EQUIPMENT

New F Series compacts fromCase

Case has launched its new F-Series range of compact wheeled

loaders that it says has been designed tominimise servicing time

and attachment changeover times while at the same timemaximise

productivity. Four modelsmake up the new range – the 4.9 tonne

21F, 5.2 tonne 121F, 5.4 tonne 221F and 5.9 tonne 321F – and

Case says that their optimal weight distribution allows them to lift

a greater pallet load than their predecessors with, for example,

the 21F XT able to lift 2,000 kg (4,400 lb), 400 kgmore than the

21E it replaces. The smaller two are available with both parallel

and Z-bar linkages and all four meet Stage IV/Tier 4 Final emission

legislation. Engine power for the 21F is 44 kW (58 hp), 48 kW (64

hp) for the 121F, and 55 kW (74 hp) for both the 221F and 321F.

The cab has been lowered tomake the newmachines easy to

transport, with the 21F and 121F both falling under the 2.5m (8.2

ft) height so that they can easily pass under a 4m (13 ft) bridge

when on the back of a truck. The newmachines also feature a

narrow turning circle to aid in accessing confined spaces on site.

Attachment changeovers are speed through the use of the Case

Connect-Under-Pressure that automatically depressurises the

connectors with no hand tools being required.

The hydraulic system delivers all the power needed to operate

themost power-hungry attachment. The High Flow option, available

on the 221F and 321F, increases hydraulic flow from 70 to 130

litres per minute and allows the use of powered attachments.

The new compact wheel loaders feature a 4-wheel drive

hydrostatic transmission that provides a 33 km/h High Speed

option on the 221F and 321Fmodels with a 2-gear mechanical

gearbox. Turtle and rabbit speed can be engaged under load for

maximum efficiency.

Targetting European

Chinesemanufacturer

Sany has been investing in

the Europeanmarket over

the past few years.

Sandy

Guthrie

visited its German

factory to find outmore

Founded inChina in1989, the company

is still privatelyowned, andhas grown

from a smallwelding company to amajor

globalmanufacturer, with a focus on

internationalisation. BartDecroos,managing

director of theEuropeanoperation, which

goes under thename SanyGermany, said

the companywas in five sectors –mining,

concrete, hoistingmachinery, earthmoving

andportmachinery. “We’re in somany

different sectors,”he said. “It is a goodbalance

compared tootherChinese companies.”

The company’s strategyhas beenone of

localisation aswell as globalisation. Bart said

therewas an acceptance from theChinese

management touse local people.He saidof

theEuropeanoperation, “It’s ledbypeople

from the construction industry, theport

industry, the earthmoving industry, etc.”

R&D is important toSany, andwhile

there is some relianceonChina for some

jointwork, the company recognises that the

regional differences are key. “Weworkwith

people in localmarkets, settingup local R&D

centres. Sanywas probably the first todo this,”

saidBart. “WithEuropeanR&D, there is local

knowledge and theyknow themarket. From

thebeginning, therehas been a focus onnew

developments, investing inR&D. About 5 to

7%of revenue goes intoR&D.”

The aftersales service is another areaof

focus for Sany, andBart said that therewas a

short lead time for spares. Part of the reason

for this is thatmanyof theparts come from

Europeanmanufacturers. “Wemade sure that

wehad spares beforewe starteddistribution.

T

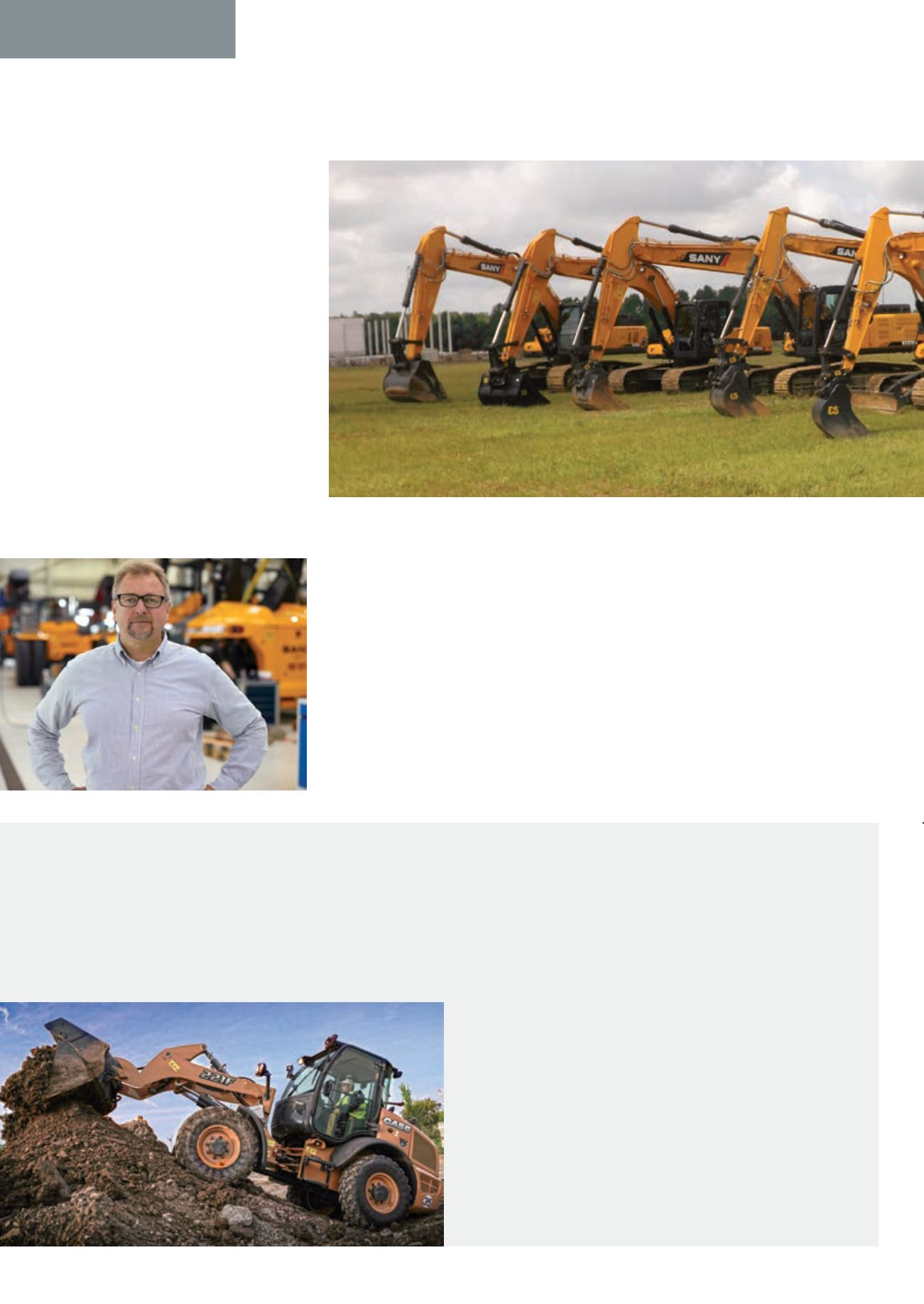

he excavatorwill be themaindriver

ofChinesemanufacturer Sany’s

globalisationplans, according to the

teamnowbased inEurope, with fivemodels

currently available for theEuropeanmarket.

These are the 6 to8 tonne SY75C, the 12 to14

tonne SY135C, the 21 to22 tonne SY215C, the

22 to25 tonne SY235C and lastly the 32 to35

tonne SY335C.

But this is onlypart of thepicture for the

Kobelcooperationbased inBedburg, near

Cologne, inGermany.

There are five Sany excavatormodels currently in Europe

Decroos, “We have confidence in the quality”