38

NOVEMBER-DECEMBER2014

d

&

ri

EQUIPMENT

All new

from JCB

JCB has unveiled an array of

newmachines, including its

first ever 10 tonne excavator.

Improved fuel economy is a

theme it is stressing across

these new launches, as

Chris

Sleight

found out

J

CBhas been rollingout newproducts

acrossnumerous product ranges,

including tracked,wheeled andmidi

excavators,wheeled loaders, telescopic

handlers, rough terrain forklifts, newvariants

to its backhoe loaders andgenerators from

JCBPowerProducts.

Perhaps oneof themost interesting areas is

themidi excavator segment. This is adifficult

area todefine accurately, but the general

meaningof ‘midi’ is taken tomeanbigger than

amini excavator, but smaller thanmainstream

excavators, so about 6 to10 tonnes operating

weight.New additions in this area include

the6.5 tonne class 65R-1, a reduced tailswing

model – a replacement for the8065RTS.

Meanwhile, abrandnew addition to the

range is the100C-1– the first 10 tonne class

excavator JCBhas ever built. The company

said itwas basedon the frameof the8.6 tonne

86C-1midi, butwith amorepowerful engine,

largerdig end and increasedhydraulic capacity

toboost performance.Keymarkets are seen as

France and theUK.

The traditional overhanging counterweight

machineoffers amaximumdiggingdepthof

4.6m (15 ft), adumpheight of 5.6m (18.4 ft)

and a reach at ground level of 7.5m (24.6 ft).

Power comes from a55kW (73.8hp)Kohler

engine thatmeets emissions regulations

without theuseof adiesel particulate filter.

JCB said this powerunit offered a10% fuel

saving compared to competitivemodels. The

100C-1 alsohas an engine auto idle function

that drops engine revs after apre-determined

periodof inactivityup to30 seconds.

Another important feature is that all

the service intervals – includinggreasing

– are500hours. JCB said, “The500hour

greasing interval is probablyonly twice a

year, compared toweeklyordailyonother

machines.”

Furtherup theweight range, JCBhas added

thenew30 tonne class JS300 crawler excavator,

which replaces the JS290. There is a reduction

in internal noise to just 70dB(A) in the cab,

andother features include ahigh specification

JCB hasmoved toMTU engines for its

Tier 4 Final 457wheeled loader and

themachine also features the next

generation Command Plus cab

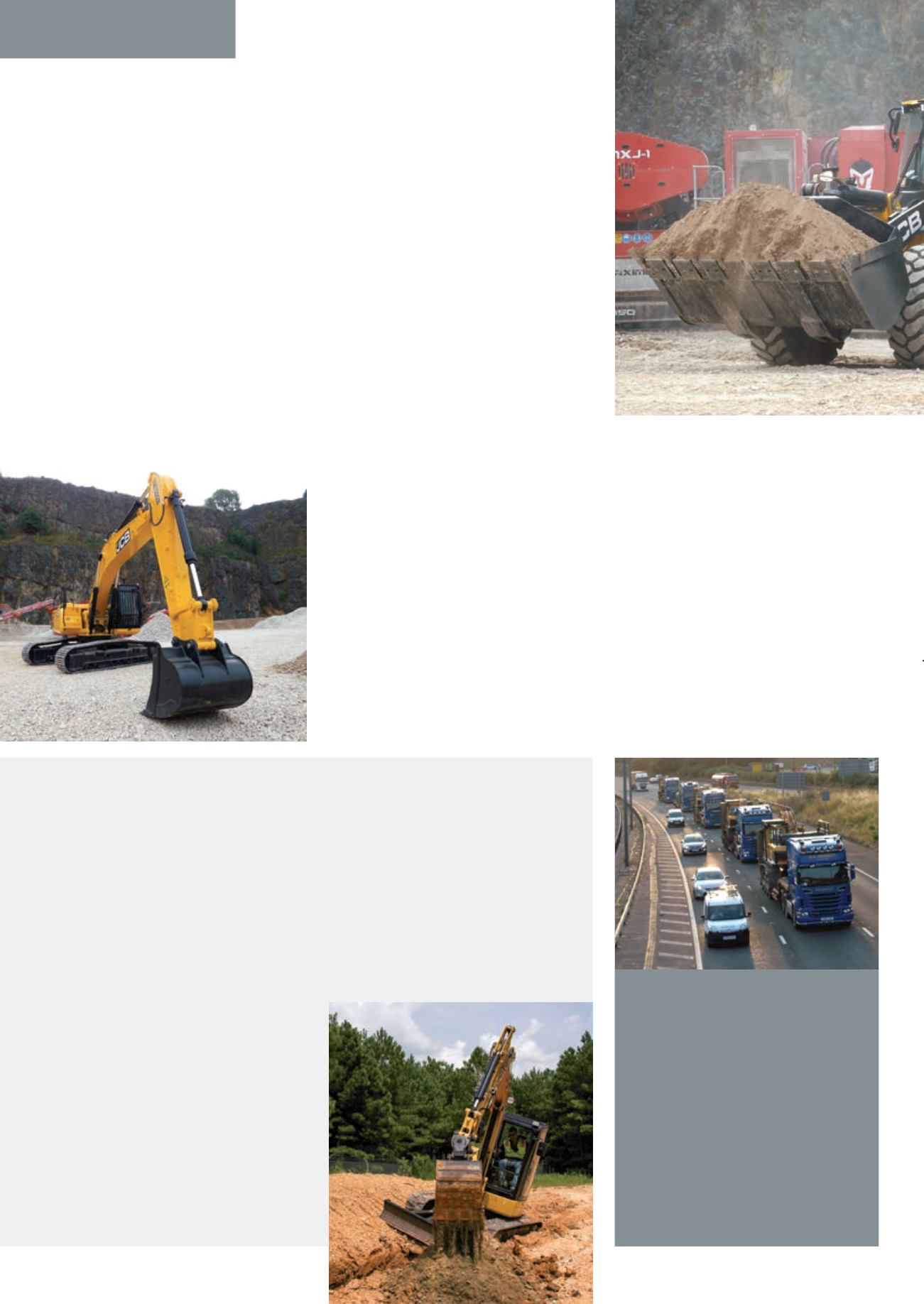

The new JS300 features a simplifiedmode selection

system and quieter cab than the JS290 it replaces

UK demolition contractor DRSDemolitionNational,

based in Avonmouth in Cornwall, has invested

close to £2million (US$3.2million) to shift its

fleet focus towards the use of Hyundai equipment.

Its order includes four R330LC-9A full demolition

specification excavators, four R220LC-9A full

demolition specification excavators, a 140LC-9A

and a 140LC-9, threeR80-9 excavators, anR55-9,

anR33-9 and anHL740-9Awheeled loader.

Themachineswere supplied throughMolson

Group, also based in Avonmouth, who is the largest

Hyundai dealer in the UK.

The newmachines are nowworking on a range

of jobs around Cornwall, including the demolition

of the oldest hotel inNew Polzeath, the Atlantic

House.

Cat introduces tilt coupler

Cat has launched a new tilt coupler for its 5 and 8 tonnemini excavators in the shape of

its newDual-Lock Tilt (DLT) pin grabber hydraulic coupler that allows use of attachments

through a 180° arc.The design provides optimum flexibility and efficiency in applications

including demolition, accommodating compatible pin-on attachments and permiting the use

of buckets in a front shovel configuration.

The DLT coupler’s design allows tools to be changed from the cab and a visible locking

mechanism assures operators that tools are securely attached. Its primary locking system

uses a wedge plate positioned via a hydraulic cylinder with integrated check valve and a

spring-applied secondary lock hydraulically released bymeans of a separate circuit.

It features an enclosed design with no external cylinder rods ormoving parts, resulting

in optimum reliability, longer component life and low cost of ownership, says Cat. All internal

components subject to wear are heat-treated formaximum service life, thus extending

the life of bearings, seal grooves and gear

surfaces. A newly designed rotary actuator

provides up to 35%more holding torque,

reduces overall weight by 15% and simplifies

hydraulic line routing. In addition, the helically

cut and hardened gears used in the actuator

ensure positive action and long-term

durability.

Coupler weights are 112 kg (247 lb) for

5 tonne class excavators plus the 903C

CompactWheel Loader and 180 kg (398 lb)

for 8-ton-class excavators. The DLT coupler

is available for 305C/D/E and E2models,

305.5D/E and E2models, and 308E and

E2models.