IN ACTION

Keeping

cool under

pressure

Bodens Group, aManchester, UK,

based wood productsmanufacturer has

taken delivery of the two additional Bell

wheeled loaders, a new L1806E and a

low-hours used L2606E, to join an existing

L1506E acquired last year. The latter is

predominantly working indoors, while the

two additional machines will be working to

load up to 200 trucks per day.

The environment in which themachines

is working is probably one of themost

arduous to be found anywhere, with high

levels of dust that can clog radiators along

with high heat levels from continuous

engine use. This dust arises from the

conversion of wood waste into biomass

fuel, sawdust and woodchip.

Bell loaders are fitted with the

QuadCool cooling system that works by

compartmentalising the radiators by

incorporating finemesh pre-filters and

wide core radiators to ensures that dust

bypasses the radiators, in turn helping

to avoid build-up and extending periods

between cooling system cleaning. The

system also includes an automatic

reversing fan to blow accumulated debris

away from the radiators andminimise the

frequency of cleaning routines.

“There are high expectations placed on

themachines in operationwithin our plant.

Each is given a long, heavy workload,

within what can only be described as

challenging conditions,” explained Alan

Whitrow, operationsmanager at Bodens

Group. “Given our high daily throughput,

we needmachines that not only deal with

the dust, but can alsomake the grade

when it comes to fuel efficiency.”

“While historically, our drivers and yard

manager have held allegiance to other

reputable vehiclemanufacturers, the

success we’ve achieved with our first Bell

loadermeant that it made sense to return

to QuadCool technology,” Alan added.

43

d

&

ri

NOVEMBER-DECEMBER 2014

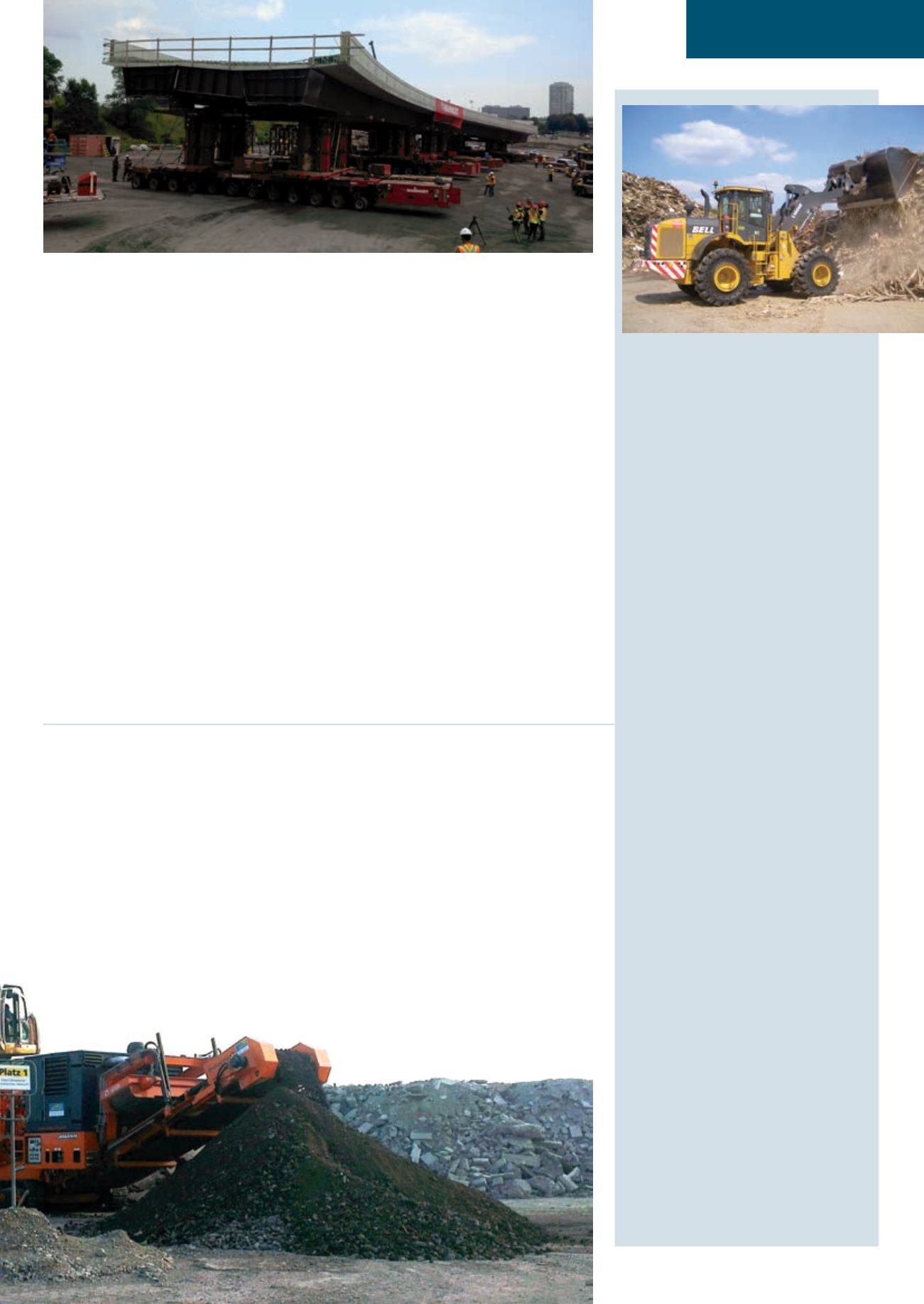

Bell loaders equippedwith QuadCool are proving

a reliable solution in a dust-laden recycling

environment

Innocrush aids

recycling

A

mannGmbH, based inSasbach in

Baden-Württemberg, southwest

Germany, has takendeliveryof adsb

Innocrush35 impact crusher that it isnow

using toprocessdemolitionwaste. The34.8

tonnemachine, poweredby aCatC11diesel

delivering287kW (385hp), has amaximum

throughput of 350 tonnes/hour.

AfterAmannhad taken avery close look

at variousmachines, the company chose

dsb Innocrush. “I needmachines thatwork

reliably. The Innocrush35 is a crusher

without anyunnecessary extras.Here they’ve

concentratedonwhat reallymatters. Themost

obvious thingwas the above-average capacity

of the crusher,” explainedmanagingdirector

FerdinandAmann.“Other advantages of the

machine are themaindischargebelt that

canbe lowered, the good accessibilityof all

components, optimum easeofmaintenance

and, of course, the simplebut verywell

thought-out overall concept.”

■

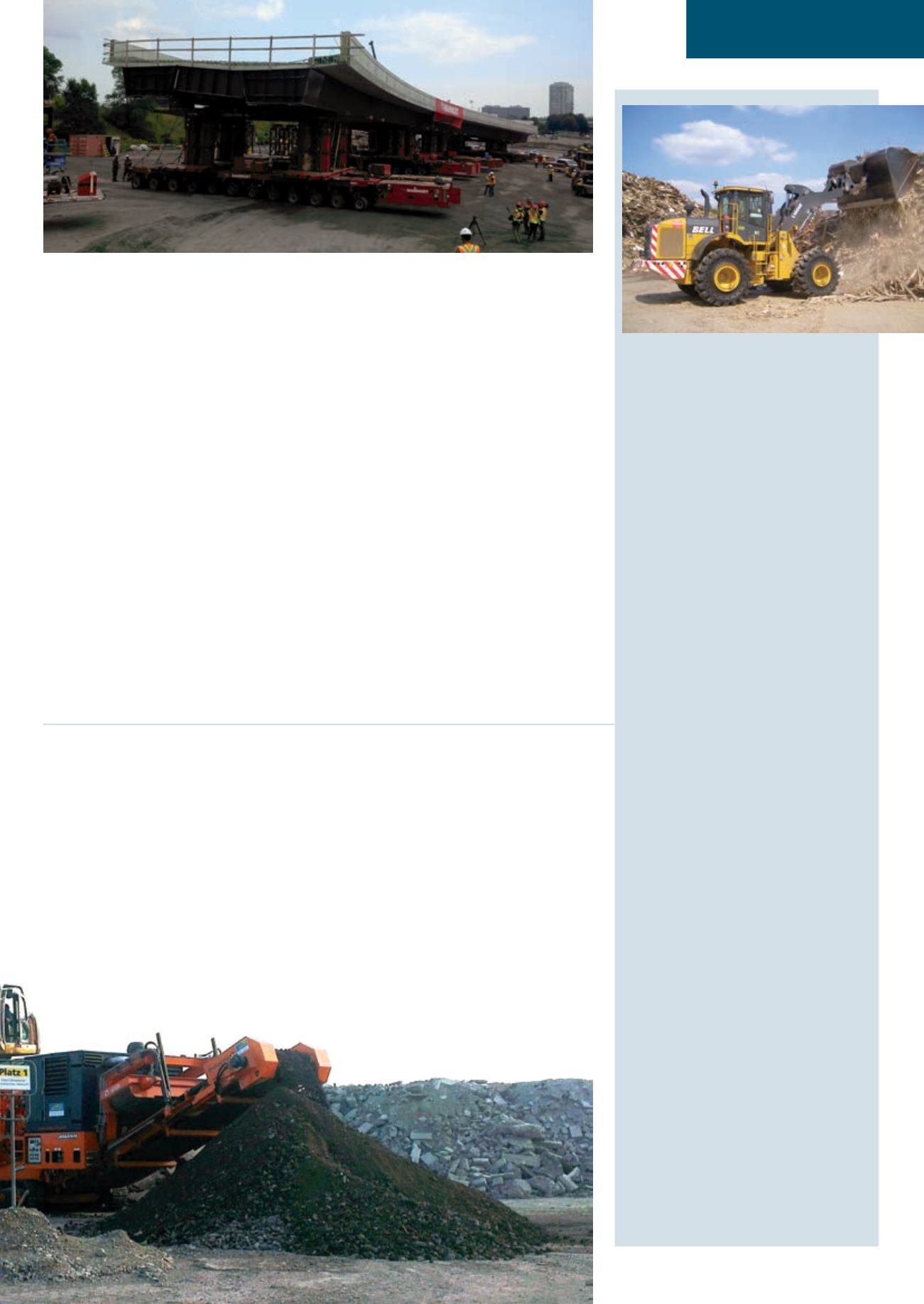

Speedy bridge lift

byMammoet

I

nternational heavy lift and transport

specialistMammoet has replaced a 2,100

tonnebridge over ahighway inOttawa,

Ontario, Canada, in a record timeof two and

ahalf hours. The replacement of the 85m

(279 ft) longLeesAvenueBridge inOttawa is

theheaviest one tobe carriedout inOntario.

Mammoetwas commissionedbyTomlinson

Ltd to carryout theproject.

The bridgewas installedusing96 axles of

self propelledmodular transporter (SPMT),

built anddesignedbyMammoet and

specialised trailermanufacturer Scheuerle,

Mammoet said. Challenges during the lift

werepresentedby the curveddesignof

thebridge. Thismade it difficult to align

the transporters beneath thebridge, a

spokesperson said. Themovewas also carried

out over a curved sectionof themotorway,

adding to the challenge.Despite this, the

The curved bridgewas installed using a 96-axle self-propelledmodular transporter (SPMT) trailer, built and

designed byMammoet and specialised trailermanufacturer Scheuerle

bridgewas installed in two and ahalf hours,

beating the expected time frameof between

four and sixhours.

SteveCripps, professional engineer and

director at theRail ImplementationOffice

for theCityofOttawa, said: “This heavy lift

projectwaswell planned and executed and an

excellent example of the teamwork required

todeliver theHighway417 component of the

OLRTProject. This projectwas another first

inNorthAmerica; theheaviest lift of amulti-

span structureover a freeway todate.”

VipinBansal,MBA, estimation anddesign

buildsmanager, said: “Once again,Mammoet

with their hardwork and efforts has proved

that they are thenumber one best company

toperform rapid lift bridge replacements.

TheLeesAve rapidBridgeReplacementwent

without a glitch and itwas a great team effort

tomake this project successful.”

■