34

JANUARY-FEBRUARY 2015

d

&

ri

SITE REPORT

through tohandover of newoperational

platforms and trackswithin a short timeframe

–oftenwith justmonths betweenphased

handovers. Eachhandover then releases the

next stageof demolition and this processwill

continueuntil all trackshavebeendemolished

fromStThomas Street in the south toTooley

Street in thenorth (a total of 16 tracks and

platforms).

Keltbray’s in-house structural engineers,

WentworthHousePartnership (WHP)

produced the temporaryworksdesigns to

enable thedemolition toproceed safely.

Due to thehigh riskprofile associatedwith

thedemolitionworksmanyof thedesigns

were checkedby a thirdparty (Cat 3 check).

Thedemolition and any lifting is rigorously

controlledbyvarious approveddocuments

such asWPP (method statements), permits to

demolish/load and lift.

Thedemolition scopeofworks includes

thephaseddemolitionof the existing station.

Activities included asbestos removal, soft

strip, removal of canopies&platforms,

temporaryworks designbyWHP, installation

of temporaryworks, demolitionof the arch

structures and footbridge, groundworks and

pilingmat installation.

Crucial to the success of theproject is

the safedeliveryof the stagedmilestones to

enable thenext stage toproceed. Byworking

24/7Keltbraywas able tomeet, and inmany

cases better, theprogramme and thereby

help to secure these critical dates. Careful

co-ordination and a collaborative approach

were essential to the successful deliveryof

eachphase. Thereweremultiple complex

demolition interfacesworking in and around

the liveoperational rail station and around

theother activities such as piling, bridgedeck

works, platform and canopy construction,

layingpermanentway,M&Eworks and

commissioning.

In addition, several possessions of the

railwaywere required to enable theworks

tobe carriedout in a safemannerwhilst

minimising the impact on the station and the

surroundingneighbours.

Thedemolitionworks varied from the

heavydemolitionof themain arches thatwere

140m (460 ft) longby40m (132 ft)wide

by7m (23 ft) high to thedemolitionof an

existing reinforced concrete ramp adjacent to

a listed façade. Eachwork areahaddifferent

constraints and thereforedifferent techniques

wereused. The items below cover someof the

works in the first stageof demolition.

Thedemolition todatehas involved the

removal of over 155,000 tonnes of brick,

concrete and fill,with a recycle and re-use rate

of over 99%.

MAINARCHES

Themain archesweredemolishedwith the

latest generationofKomatsuPC360 excavators

mountedwithhydraulichammers. Temporary

workswere installed along the cut line to

ensure the liveplatform just 3m (9.9 ft) to the

north remained stable throughout.

A significant temporaryworks schemewas

required to the east to stabilise the existing

buttresswall. This involved the installation

of tensioned tie rodsup to50mm (2 inches)

indiameter and steelworkprops toprovide

stability to the remaining arches.

STAINER STREET SOUTH

This sectionof structurewas constructed

from concretebeams rather thanbrick arches

due tobombdamageduringWorldWarTwo.

Additionally, the closeproximityof theShard

building and a live fire escape routebelow

provided additional constraints. The solution

was to saw cut along thebeams and then lift

themout using a250 tonnemobile crane.

OLDRAMP

Cut and lift techniqueshad tobeusedon the

OldRamp section to ensure the existing listed

façadewas left undamaged. The existingpiers

wereused as temporaryprops andbyutilising

the strengthof the existing concrete structure,

temporaryworkswerekept to aminimum.

The elementswere liftedout in aweekend

possessiondue to theproximityof the railway

and thepotential collapse radius of the250

tonnemobile crane.

FOOTBRIDGE

Early removal of the footbridgewas required

tominimise theworks in the following stage

therefore thebridgewasdismantledover

the live railwayduringnight lineblocks and

possessions. The structurewas cladwith

scaffold to facilitate theworks.Oncede-clad

themain structuralmemberswere liftedout in

apossessionwith a250 tonnemobile crane.

With somany sensitiveneighbours

environmental issueswereof utmost

importance and therefore themanagement of

noise, dust andvibrationwere critical to the

continuedprogress and success of theproject.

Noisemonitoringwas set up around the site to

monitor against levels set out in theSection61

Agreement as agreedwith the local EHO. This

is a formal agreementwith the local authority

that sets out theparameters and limits for

noise, dust, vibration andworkinghours for

theproject.

Best PracticableMeans (BPM) isused at

all times tominimisenoise generationon

site.Noise screens andother localisednoise

reductionmethodswere employed tohelp

reduce the levels. For example, pulverisers

wereused rather thanbreaker attachments,

switchingoff engineswhenplant isnot in

use. Local businesses,GuysHospital and

residents arekept informedbyCostainof any

works thatmay result indisruption. Start of

shift briefings includemeasures tobe taken

tominimisenoisewhenworking around the

hospital, businesses and residents.Vibration

monitoringwas installed inGuysHospital to

monitor critical equipment in this building.

No triggerswere reached andno complaints

were receivedduringKeltbray'sworks.

Demolitionofmassivebrick structures

in a city environment has thepotential to

releasedust therefore several dust suppression

unitswereused to control this aspect of the

works. Thesewas set up along the lengthof

thedemolitionworking face anddirected to

the appropriatedemolition activity to ensure

dust releasewasminimised.Dustmonitoring

is carriedout on site and around the site

perimeter byCostain. Pollutionprevention

was furthermanagedby ensuringmaterials

andwastedidnot enter anydrainage system,

fuelwas stored away fromdrains indrip trays

protected fromvehicular traffic inbunded

fuel bowsers located in a secureCOSHH

area and refuelling,wherepracticable,was

carriedout at adesignatedpoint equipped

withdrip trays and spill kits, and ensuring

that operatives are trained in theuseof spill

kits andprocedures for removal of fuel/oil

contaminatedmaterial.

■

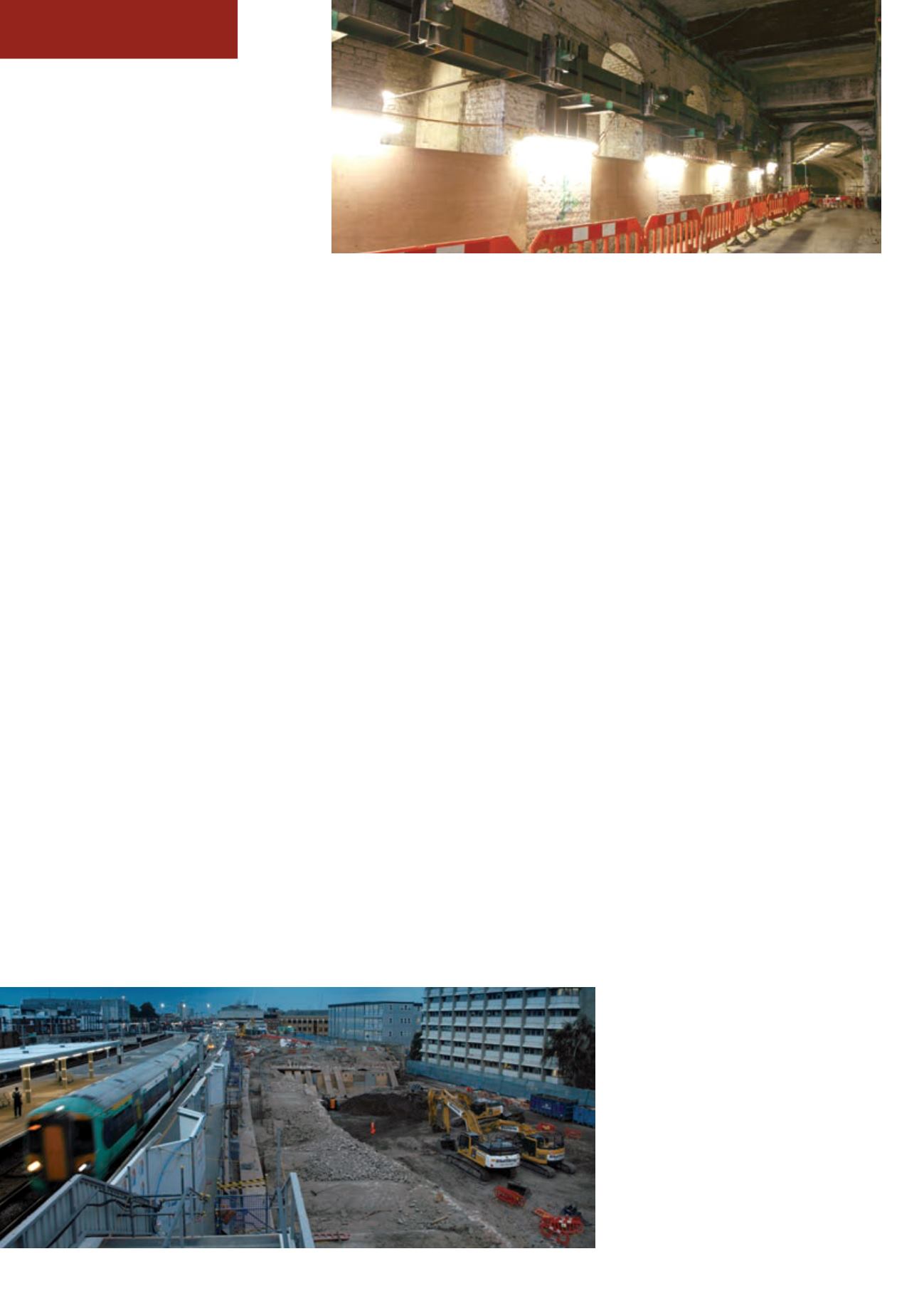

A tension tie rod schemewas

designed byWentworthHouse

Partnership

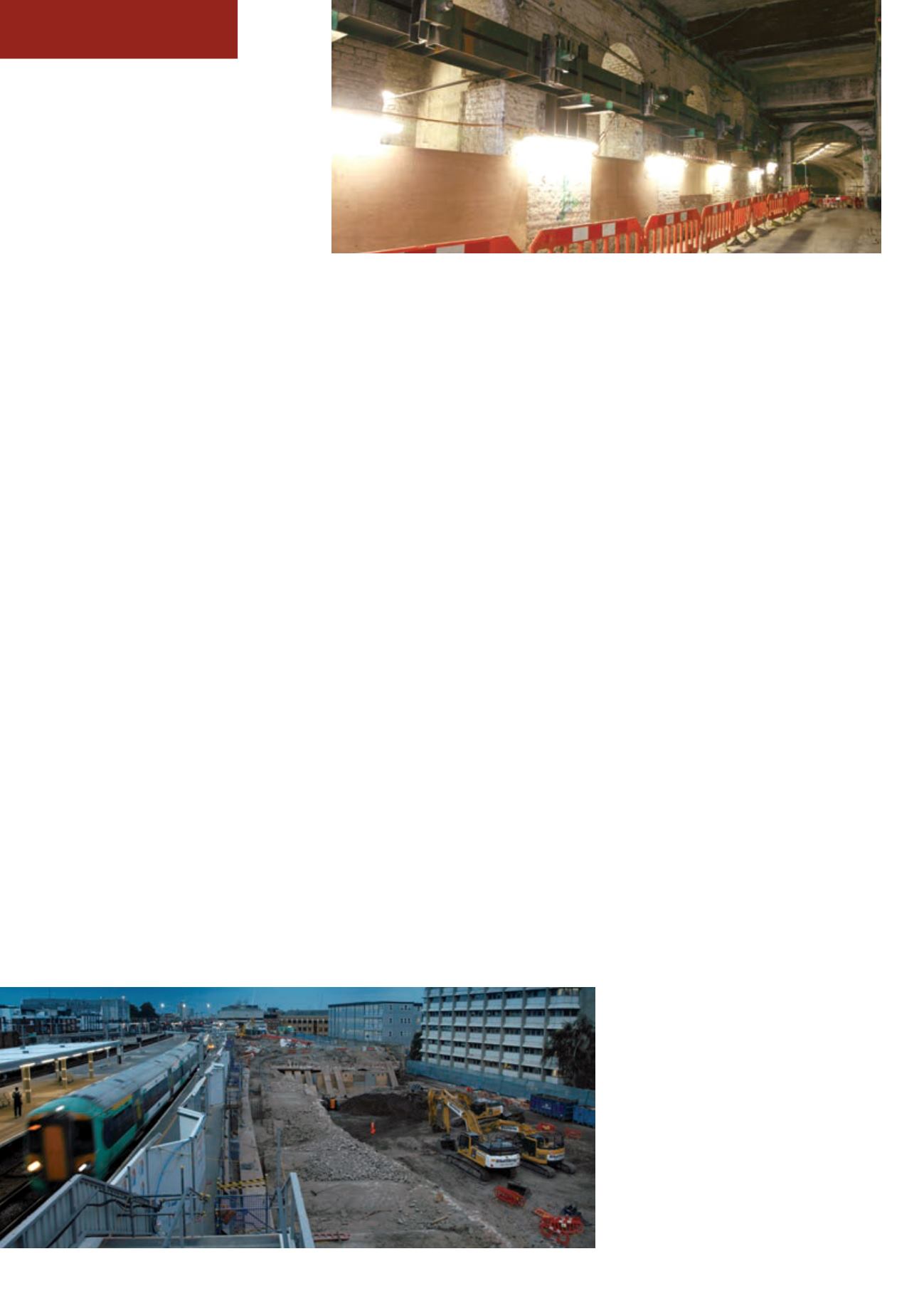

Work could not be allowed

to interferewith the smooth

operation of the station