25

d

&

ri

JANUARY-FEBRUARY 2015

INDUSTRIAL

DEMOLITION

C

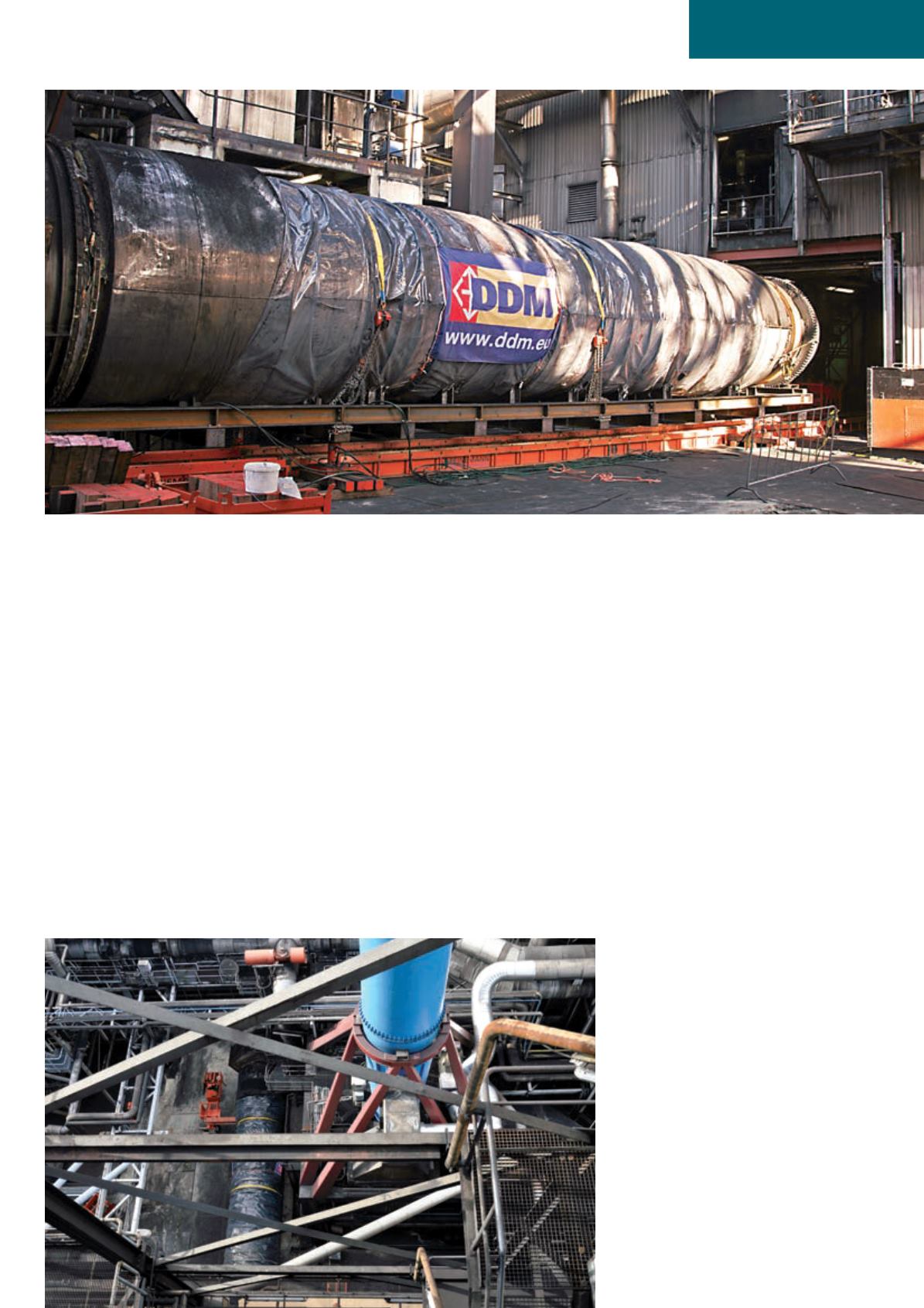

abot BV, a large chemical company

located inRotterdam,Netherlands,

taskedDDMwith the removal of two

largedryers located in theheart of its facility,

whichproduces rubber carbonblacks. These

dryerswereplaced right in theheart of the

factory andwere tobe replacedby twonew

units fabricatedon-site. Finding thebest

removalmethodof theolddryers and the

installationof their replacementswas the

challenge.

Cabot had already spent some time

consideringmethods prior to its contacting

DDM, whobegan theworkwith an initially

small team consistingof a cost and a technical

engineer. Cabot’smainprioritieswere

safeworkwithout any incidents, a short

turnaround, extremely tightworking spaces

and theminimisationof disturbance to the

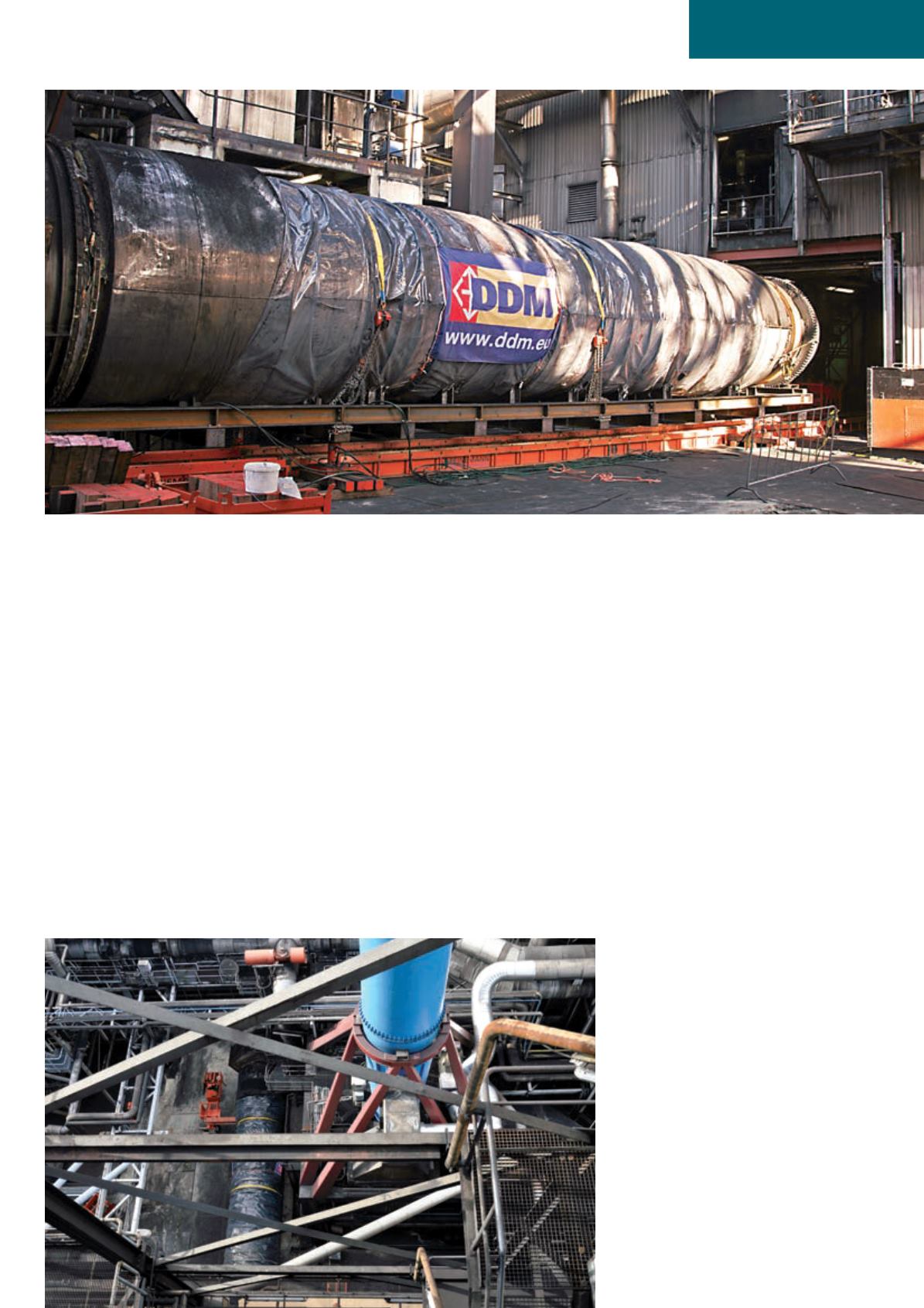

operational plant.Anothermajor concernwas

thenecessary equipment lifts over liveprocess

equipment.

Working together, Cabot andDDM

established adetailedplan to replace the

dryers, with a lifting and rigging company

brought in that becamepart of the team led

byDDM. In thebackground therewas the

company responsible for the fabricationof

thenewdryer. Becauseof the ‘out-of-the-box’

thinking adoptedbyDDM, an entirelynew

approach to theworkwas adopted.

Firstly all possiblehazardswere listed

byDDM’sHSEQdepartment – risks

were identified, categorised and assessed.

Measures are thendescribed and taken to

dealwith these risks.Onlywhen the riskhad

been eliminatedorminimised couldwork

commence. The sequenceof activitieswas

complexdue to the fact that a lot needed tobe

done in a short periodof time.Anumber of

differentmethodswereused and thenumber

of parties necessarily involvedgrew. Togive a

clearer insight of the removal process,DDM

decided to create a3D animatedvideo that

showed every step in theprocess. Everyone

involvedwas able to seehow theworkwas

tobe executed. The extensive time schedule

anddetailedworkdescription supportedby

this 3D animationwas key to successwith the

work.Despite a tight time schedule for the

removal, workwas actually completedoneday

early.

Prior toDDM’s involvement studies had

shown itwas best to separate thedryers and

lift themout through andover the roof. To

minimisedisturbance to theproduction

process and reduceoverall costs for the client,

DDM chose tonot use thismethod, but

Netherlands contractor DDM

was taskedwith the removal

of an outdate dryer in

confined spaces surrounding

by working industrial

operations that called for

lateral thinking.

D&Ri

reports

on the resulting project,

shortlisted for the 2014

Industrial DemolitionAward

A tight squeeze

>

26