29

d

&

ri

JANUARY-FEBRUARY 2015

CRUSHING

EQUIPMENT

thesedesiredproduct sizewith just theMFL

jaw crusher teamedwith the SBM impact

crusher.

Havingbuilt anewUKproduction facility,

RedRhino crushers has expanded its rangeof

mobile and static jaw crushingmachines used

for a varietyof contractingwork and civil

engineeringprojects. Business development

manager JohnBird explained therewerenow

six crusherswithin its range.

He said: “Weoffer diesel, electric and

hydraulic options.Wehave the latest variance

inoutput size and are currentlydesigning and

workingonbringing twonewmachines to

themarket in2015 - a three tonne size impact

crusher designedwith the recycling andglass

industries inmind and a 3.2 tonneRedRhino

mini screener capable of screeningup to80

tonnes per hour.

“Wehavenow sold close to500 crushers

throughout theUK,USA, Canada, Europe

andAustralianmarkets, withgrowing

demand fromSouthAfrica and theFarEast.”

TerexFinlay alsohas considerable

expansionplans for its rangeofmachines,

material canbedefined simply and easily,

aidingprecisionof screening curves.

The conveying velocity continuously

adapts the crusher load and theoperating

pressureof themain conveyor, whichprevents

overload anddowntimes. If necessary, the

vibrating feeder canbe infinitely controlled

manually via the remote control.

Competingwithharsh climates is often

akey consideration for equipment for the

crushing and screening sector.

One example of performanceunder testing

conditions is SBM’s STE100.65.T combined

with itsRemax132ECOoperating in the

Tschita regionof Siberia. Themobile track-

mountedprimary and secondary crushing

unit, consistingof a jaw crusher and an

impact crusher, is loadedherewith especially

hard and toughgabbrobasaltwith a feed size

of up to0.6m (2 ft).With a throughput of

some 200 tonnes anhour, a final grain size of

0-45mmwas achieved.

Traditionally inRussia such a taskwould

be carriedout using two further crushers so

there is anobvious advantage in achieving

McCloskey appoints NZ

dealer

Auckland, New Zealand, based Sanland Equipment has been added toMcCloskey’s

global distributor network. Trevor Heaphy of the former noted: “in the next five years,

we anticipate growth in the aggregate sector as New Zealand steadily pulls out of the

global financial crisis. In addition, concrete recycling is becoming amore visible sector.

McCloskey’s range of mobile crushers and screeners have a proven track record in this

application – it’s a well-known and respected brand that offers the full range of products.”

John O’Neill, vice president of marketing and sales at McCloskey, said of the addition:

“Having Sanland on board will further strengthen our distribution network globally. New

Zealand is amarket with huge potential, particularly in quarrying and recycling. These

present some unique and exciting possibilities that we anticipate will contribute to our

growth in themarketplace.“

The new PremiumQI441 tracked impact crusher

sharesmany of the features of the company’s QI440

New impactor

fromSandvik

The bauma China trade showwas the

stage that Sandvik used to introduce

the new PremiumQI441mobile tracked

crusher that uses the revolutionary

CI421 Prisec Impactor box. Sandvik has

redesigned the crushing chamber to allow

the base crusher to easily be switched

between primary and secondary mode to

effectively give users twomachine in one.

The QI441 retainsmany features of the

proven QI440, such as direct drive, large

feed hopper, underpan feeder, PLC control,

remotely operate inlet opening adjustment,

overbandmagnet, prescreen and ceramic

blow bars as standard on amachine that

features lowwear, easymaintenance and

low cost per tonne operation.

The versatility of the QI441 is further

ensured by a range of optional extras that

allows the crusher to preciselymatch

the demands of the customer’s specific

application including a unique Doublescreen

double-deck hanging screen with

recirculation system. This is of particular

benefit as conventional hanging screens

are often a limiting factor with high capacity

impactors, forcing the customer into an

expensive secondary screen purchase.

However, the on-board Doublescreen is

designed tomatch themaximum capacity

of the crusher, allowing the production of

accurately sized products for immediate

use at source from onemachine.

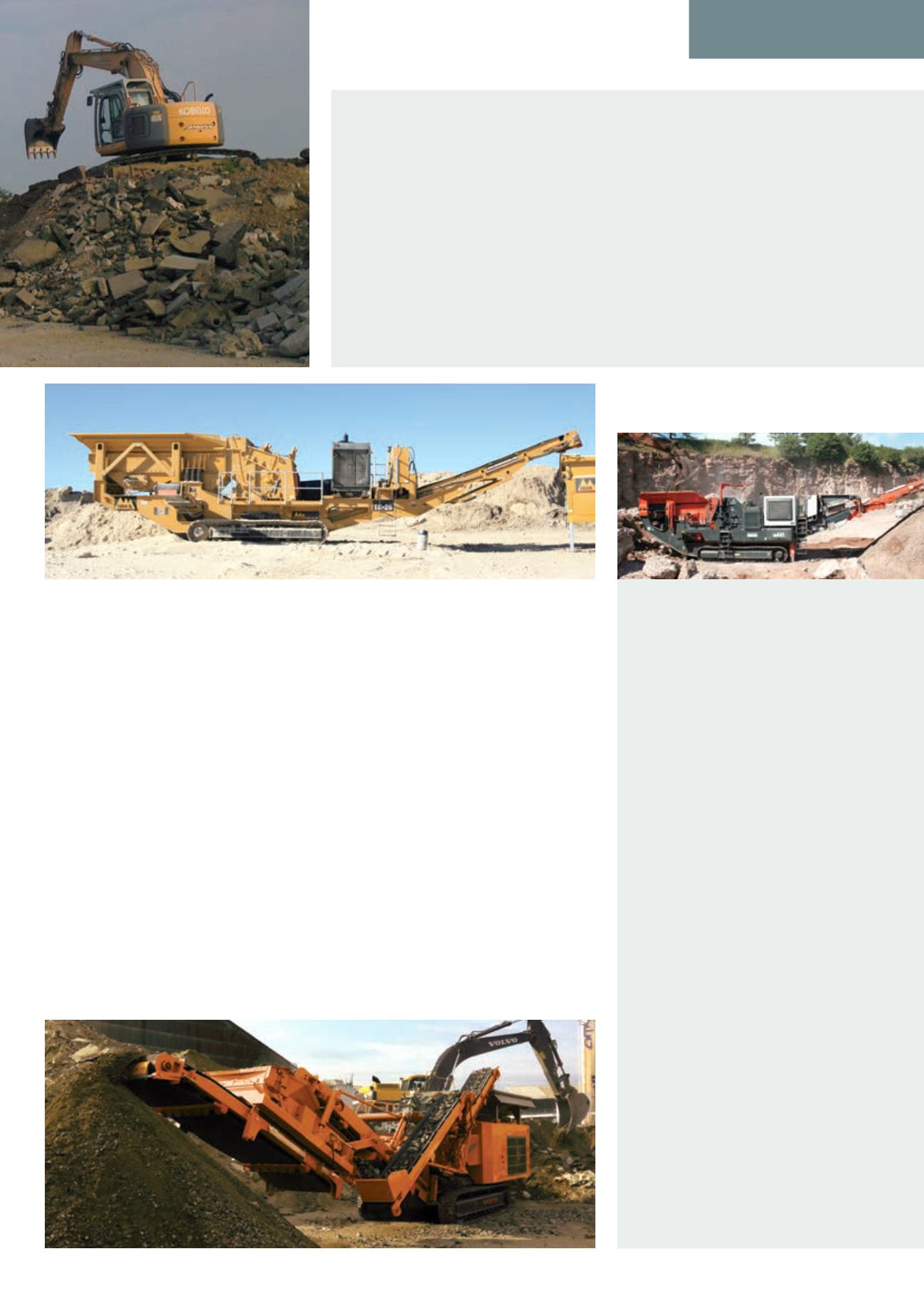

IROCK’s TC-20 crusher in action after its release this

year in the USA

Rockster R110DS offers a flexible

design, according to its developers