37

d

&

ri

JANUARY-FEBRUARY 2015

EQUIPMENT

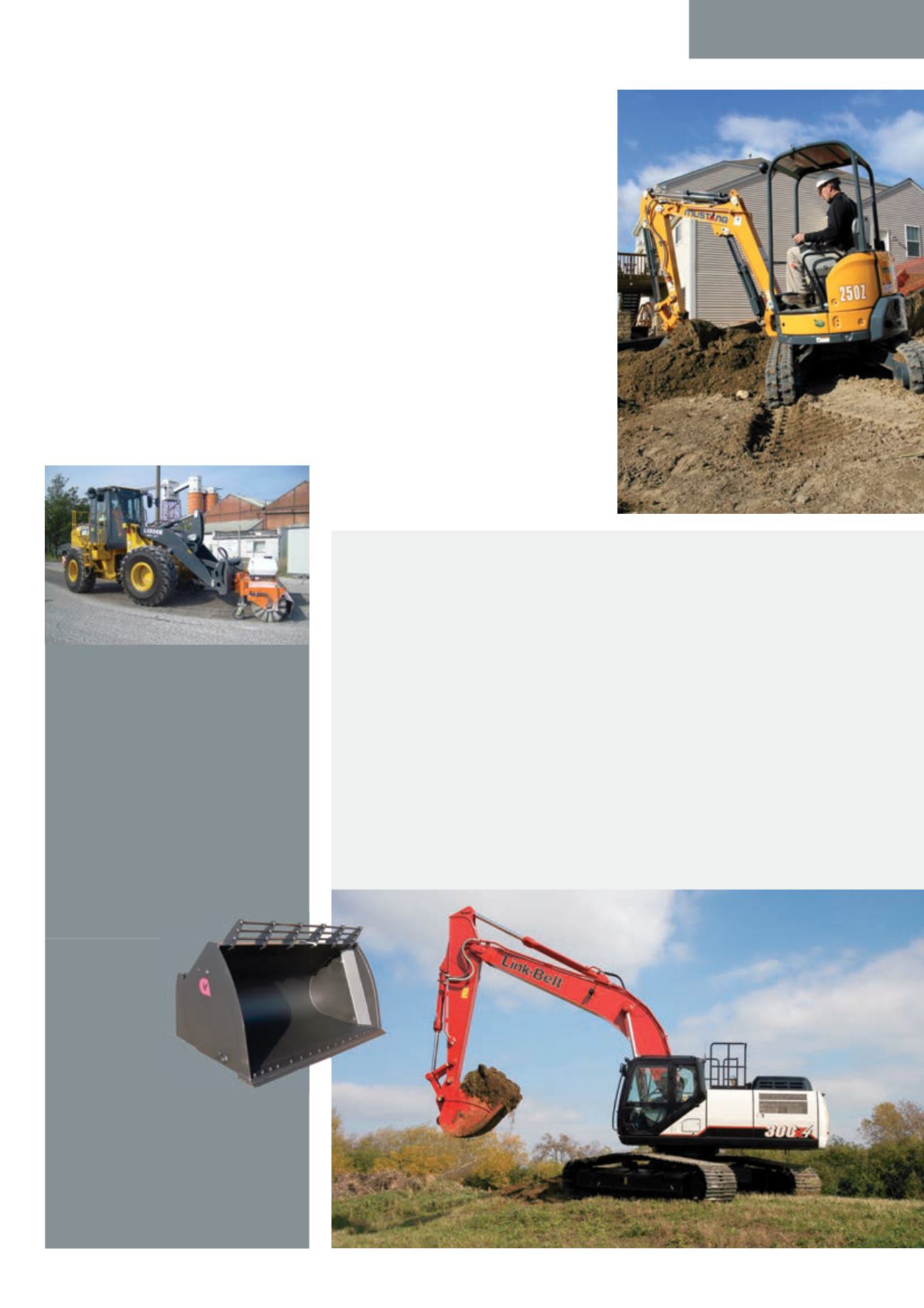

Mustang’s

new compact

M

ustanghas introduced the 250Z

compact excavator forNorth

American customers, which it

claims offers innovative features that enhance

productivity, operator comfort, efficiency and

cost savings on site. This compactmachine

provides 20 cm (8 inch) deeper digdepth at

2.9m (9.5 ft) and21 cm (8.3 inch) additional

reach at ground level compared to the

previousmodel, the 270Z, which it replaces.

The250Z is equippedwith a15.2kW (20.4

hp) electronically-controlledYanmarTier IV

emissions certifieddiesel engine.No engine

regeneration is requiredon the250Z, reducing

Fittedwith a cab,Mustang’s new 250Z

excavatorweighs in at 2.8 tonnes

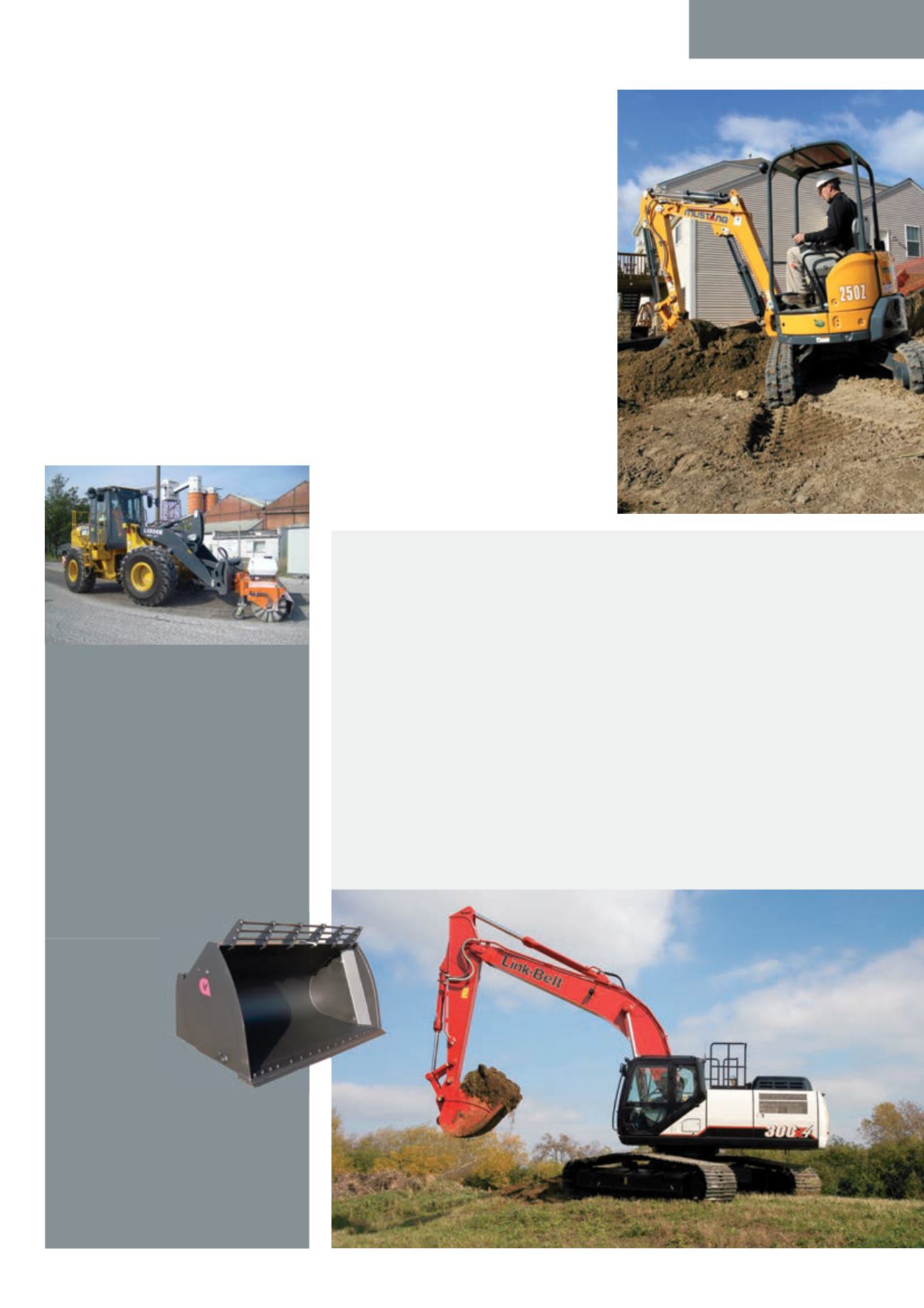

Link-Belt’s 4x4s

Link-Belt has introduced four new Tier 4 compliant tracked excavators for the North

Americanmarket in the shape of the 25 tonne 250X4, 28 tonne 250X4LF, 30 tonne

300X4 and 37 tonne 350X4, all of which are powered by electronically controlled

Isuzu diesel engines that provide fuel savings of up to 12%, claims the company. Diesel

particulate filters (DPFs) are not required and this emissions solution is used across all X4

models.

New features include a 30% larger hydraulic control valve that creates a larger hydraulic

passage area, larger spools and advanced controls tomaximise hydraulic system control

and responsiveness. Two electrically-controlled Kawasaki variable-displacement axial-piston

pumps and one Kawasaki gear pump assure that hydraulic flow is delivered precisely

when and where it is needed. The result ismoremanoeuverability and precision across all

operatingmodes, smoother machine operation and up to 12% faster cycle times.

Tomaximise uptime, X4 excavators are equipped with Link-Belt’s RemoteCARE GPS-

enabled telematics system, enabling round-the-clock remotemonitoring and security. This

tracks routine andmajor service intervals, as well as current machine health, providing

more flexibility and control when determining when and where to servicemachines. The

system also providesmachine location in real time for better job supervision and remote

security monitoring.

downtimeon site.A low exhaust positionon

themachine reducesnoise, increases safety

and improves visibility.Cold-weather starting

is easywith an electric glowplug starting aid,

reducing theneed for blockheaters or starting

fluid.

The controls on the250Z include a

proportional auxiliaryhydraulic rocker

switchwithdetent on the joystick. This

allows theoperator to adjust thehydraulic

flow forprecise attachment performance

whilekeepinghis/herhands on the joysticks.

Theoperator can easily select standard ISO

or anoptional backhoe control patternwith a

turnof amechanical lever. The two-position,

high speed travel switch is conveniently

integrated in theblade control lever for easy

accessibility.

■

The 30 tonne 300X4 is one of four new

Link-Belt X Seriesmachines thatmeet

Tier 4 Final emission requirements

■

NewWest Gypsum has taken delivery of two

newBell L1506Ewheeled loaders for use at

the company’s plasterboard recycling facility in

Avonmouth, UK. This application is considered

to be one of the harshest environments for such

machines towork in, as the fine airborne dust

created during the recycling process can cause

engine failures and resulting downtime. The

company’s experience of using other Bell loaders

prompted the purchase, with the ‘QuadCool’ system

fitted toBell machines combating the risk of dust

build-up, using compartmentalisation of radiator

technology as part of its design. This prevents

clogging and overheating that subsequently

reduces downtown, aswell as the required

frequency of cleaning routines to help keep

machinesworking productively.

■

Viby Attachments

has introduced a new

version of its Hy-Tip

bucket for compact

and backhoe loaders

designed for handling

low densitymaterials,

typically below 1,000

kg/m

3

. The new bucket is

aimed atwheeled loaderswith

amaximum operatingweight of 10.5 tonnes or

backhoeswith amaximum operatingweight of

8 tonnes. The bucket features a substantially

increased dump height as it is hydraulically lifted

from its built-in frame. According to the company,

the new bucket is ideally suited to the recycling

sectorwhere it believesmachine size and

operating cost are especially important.