44

JANUARY-FEBRUARY 2015

d

&

ri

IN ACTION

Brokks on

stage

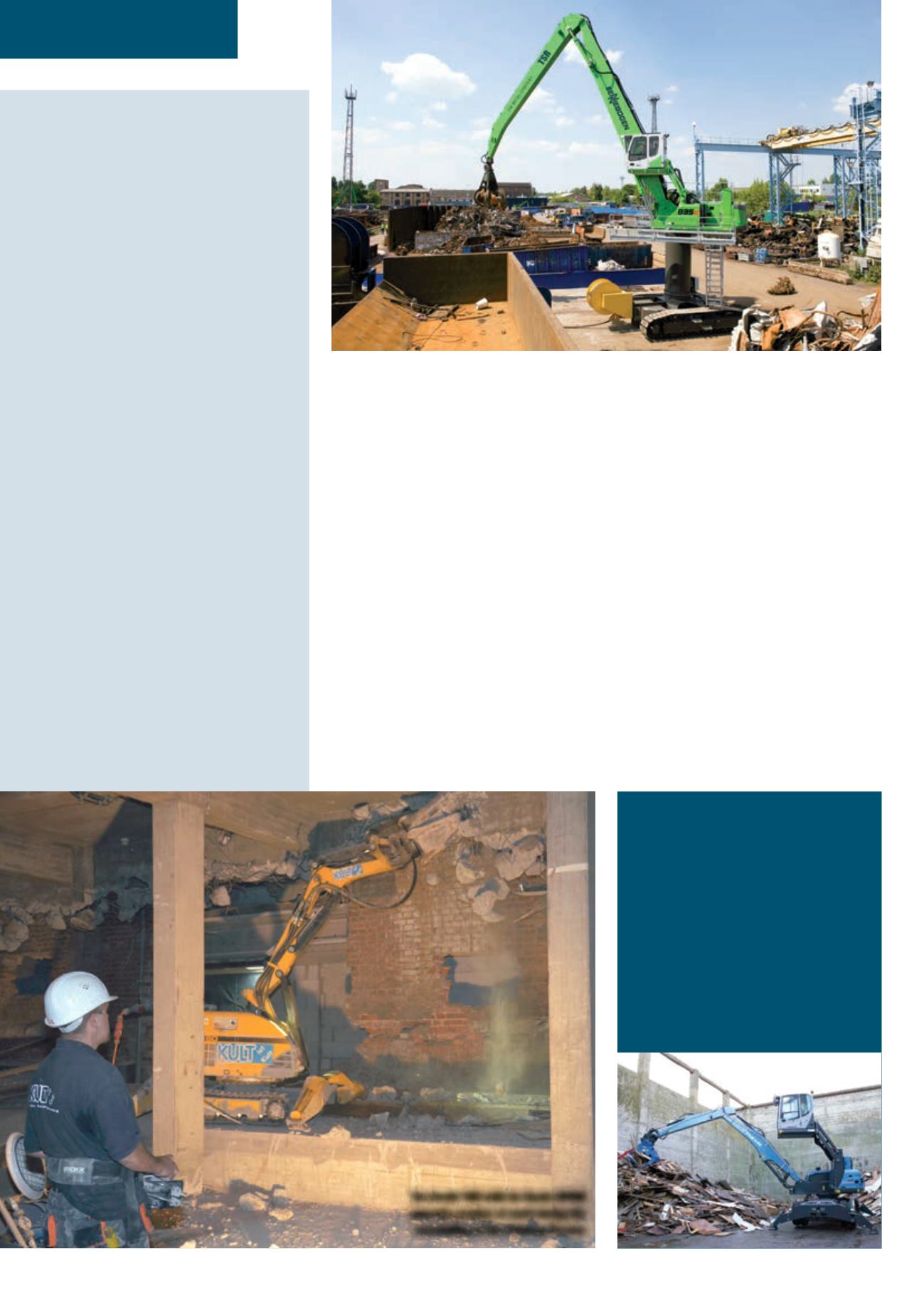

Two Brokk demolition robots have been at

work on the remodelling of the structure

of the Freiburg Theatre in Germany.

Contractor Kult -Tiefbau - Abbruch –

Entsorgung, based in Oberned, used a

Brokk 160with a Darda CC420 crusher

and a larger Brokk 330with a Darda

CC560 crusher. The twomachines

removed and processed approximately

170m

3

(6,000 ft

3

) of reinforced concrete

and 110m

3

(3,880 ft

3

) of masonry in

several stages within six weeks.

This, the third phase in the renovation

of the building, called for the installation of

new stage equipment in the stage house,

as well as a sub-stage and a two-story

revolving stage with an integrated transport

platform. Before construction could begin,

demolition was necessary tomake room

for the new equipment.

The work imposed several challenges.

First, the offices in the theatre were in

normal use during the renovation, requiring

that noise and dust be kept to aminimum,

exhaust emissions could not be permitted

and access to emergency exits could not

be obstructed or restricted, Access to the

work area was only possible through the

service entrance at the rear of the building

that in turn was only accessible via a heavily

used cycle lane. Another consideration

was the fact that only a single service hoist

was available within the building. Taken

together, these requirements ruled out

the use of larger standard construction

equipment and led to the two Brokks being

deployed to carry out the necessary work.

T

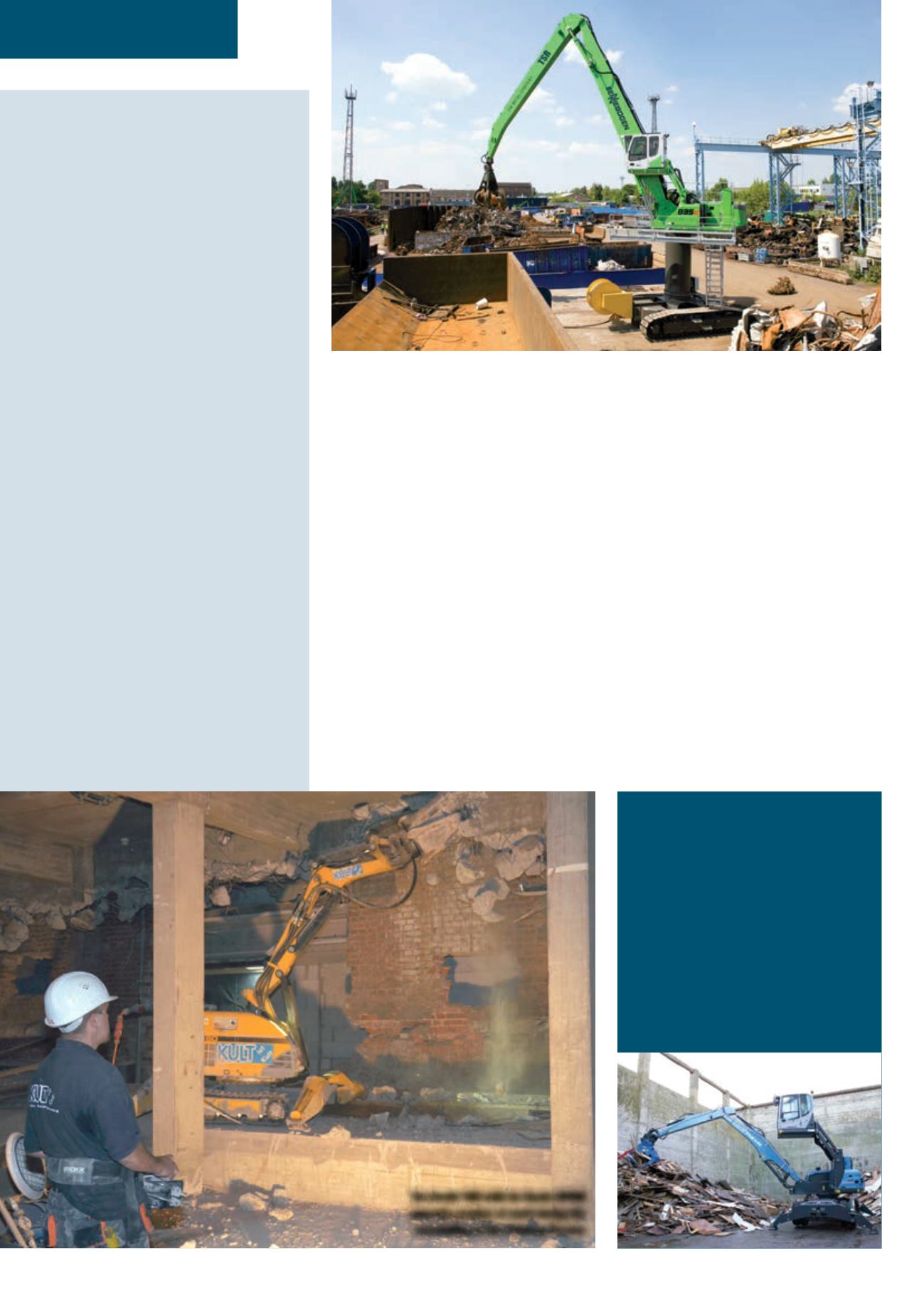

SRRecyclingGmbH&CoKGoperates

from150 locations inEurope, Russia

andChina, and relies onmakinguse

of sustainable solutions, includingwhere its

handlingmachines are concerned. As a result,

it has recently takendeliveryof a 55 tonne

SennebogenE-series 835 crawler special,

which it is usingprimarily for charging the

scrapmetal shear and loading rail cars and

trucks.However, thanks to themachine’s

mobility it is alsobeingused at other locations

on the site as required, particularly at times

of reducedproductionwhen it replaces the

company’s other diesel-powered equipment to

assistwith reducing fuel costs.

Equippedwith a35m (115 ft) trailing

power cable, themachine is poweredby a160

kW (215hp) electricmotor andhas a reach

ofmore than20m (65 ft).When sorting

materials andwhen charging the scrapmetal

shears theoperatorhas anunobstructedview

of hiswork area from the cab. Sennebogen’s

Maxcab,which canbe elevated2.7m (8.9 ft)

togetherwith an additional 3m (9.9 ft) of

height through theuseof apipe-pylon, offers

theoperator aviewheight of 8.8m (28.9

ft).An extensive lightingpackage and two

surrounding cameras offer optimal visibility

and thehighest level ofwork safety.Additional

walkways and railings on theupper carrier

body ensure ideal accessibility and safe

maintenance.

■

Ayrshire, Scotland, based Lowmac Recycling

is the first customer in the UK to take delivery

of a compact long reach Terex-FuchsMHL250E

materials handler. Supplied by distributor Blue

Fuchs, themachine is now being used for sorting

and loading duties at the company’s Ayr facility.

TheMHL205E, introduced at last year’s RWM

show in the UK, is a 15 tonne classmachine, with

the unit supplied to Lowmac featuring four point

hydraulic outriggers that allow amaximum load

of 10 tonnes at itsmaximum reach of 9m (29.5

ft) and a hydraulically elevating cab that gives the

operator amaximum 5.2m (17 ft) raised line of

sight for optimum load and site visibility during

working cycles.

Scrap powered

by electricity

TSRRecycling has recently taken delivery of a Sennebogen E-series 835 crawlermachine forwaste handling

duties at its Halle facility in eastern Germany

TheBrokk 160with its Darda CC420

concrete crusher atwork during the

remodelling of the Frieburg Theatre