14

JANUARY-FEBRUARY 2015

d

&

ri

DEMOLITION

EXCAVATORS

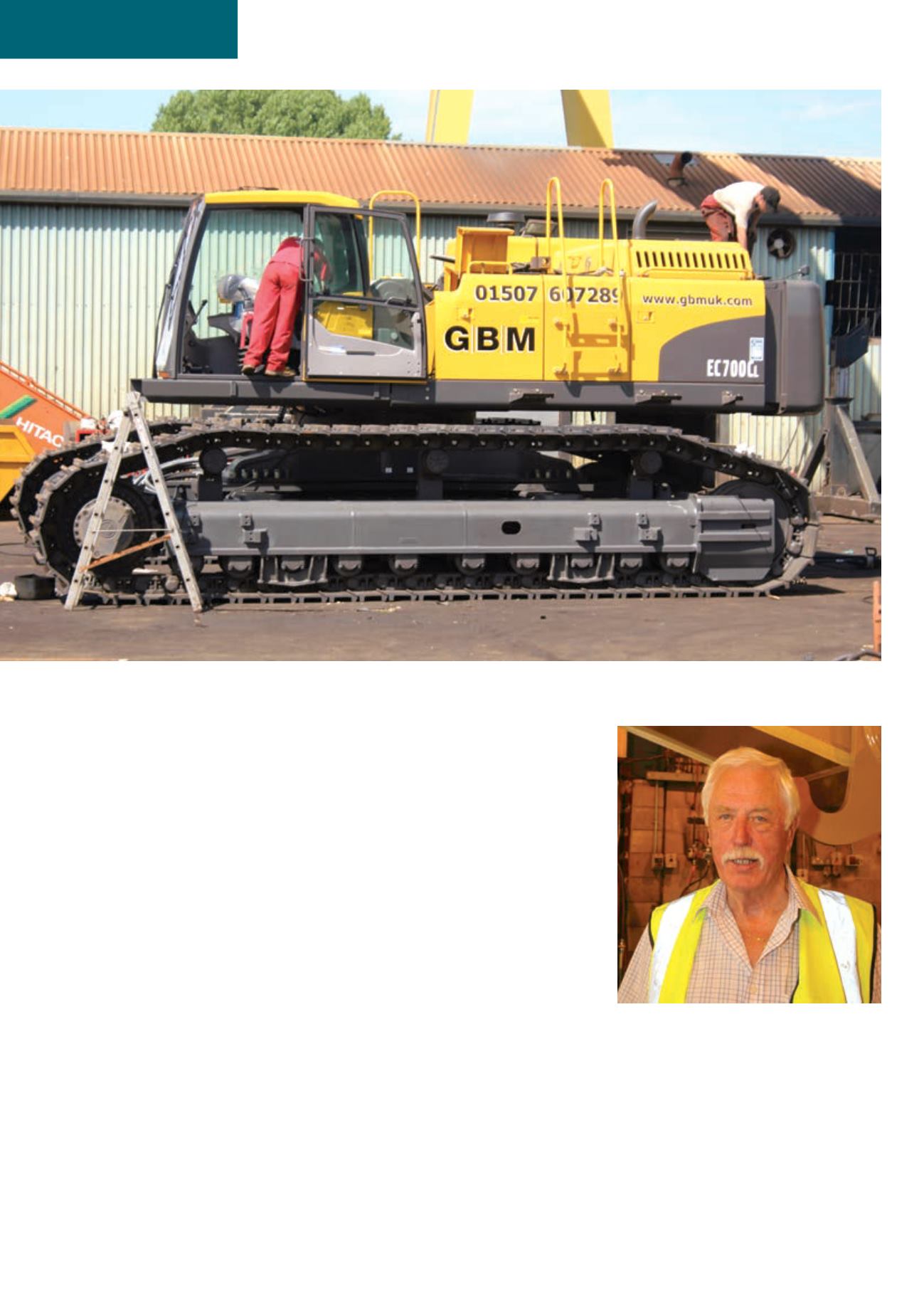

A Volvo EC700CL carrier undergoesmodification

work at Kocurek’s Ipswich facility for its new

demolition role

Kocurek’s Ron Callan has been at the forefront of high

reach developments overmore years than he cares to

remember

machinesweighing45 tonnes at that time,

whenwe startedgoingup inweight class, then

it becomes an evenmore critical factor. The

conceptDavid cameupwith allowed the front

end tobe changed in just 30minutes, which

was an absolute god-send.”

While themodular joint is obviously a

highlight ofKocurek’s success inRon’smind,

there areothers.He said: “Of course, there is

thedevelopment of the telescopic boom. That

tookus into another realm and allowedus to

move tobiggermachines. Inmy view, a three

pieceboom is not an ideal solution to reach

theheights that a telescopic cango to from

a stabilitypoint of view and the toolweight

suffers aswell.”

There are anumber ofOEMs producing

high reachmachines in the small tomedium

height range, up to30m (98 ft) or sowho

specify a 2.5 tonne toolweight.Given the

customer demandRonhas already identified

for larger tools, does he think theseOEMs

will have to respond to this demand?He

said: “I think they’ll have to. I justwonder

whether the sizeof themarket is sufficient

for them to continue toproduce their own

demolition front ends for their base carriers.

Numbers is thename of the game for them,

with their productionprocess similar to car

manufacture.However, theremaybe a feeling

on their part that theyought tohave such

equipment available in their product range

so I don’t know ifwewill ever get ridof abit

of the competition, but it is nice to thinkwe

might.”

■

height of thebighigh reaches has gone from

a relativelymodest 40m (130 ft) or soup to

90m (295 ft). Kocurek itself has taken its

machines up to themid60m (200 ft) range

but Ronhas firm views on the subject.

He said: "Height has not become the

be-all and end-all. People are beginning to

look at theweights that thesemachines can

carry in terms of tools.Whileheight is still a

requirement and still has apart toplay, tool

weight has become thedominant factor.On

theheight sideof the argument, the feedback

I havebeengetting for the operators of these

machines is that theydonot feel comfortable

withgoingmuchhigher.”

Ronwent on: “We get up to67m (220 ft)

and it is obvious that someonewill pushus

to70m (230 ft). I don’t thinkwe are terribly

keen togo that high, but at the same time I do

not seeus resisting if a customerwants it.”

Ronhas beenwithKocurek from the start.

He said: “I joinedKocurek in1998, andDavid

Kocurek alreadyhadoneor twoof themore

simplemachines into themarket andhad just

comeupwith themodular joint concept, with

the latter being the absolutemakingof the

company in someways. Thebiggest problem

at the timewaswhen a contractorwon ahigh

reach job, andgot amachine for it, if hehad

nootherwork suitable for themachine, it just

sat in the yardbecause itwas such amajor

task tomanually switch the front endover.

Such an expensivemachine sitting idle is not a

good situation for a contractor tohave.”

“Consideringwe are taking about