13

d

&

ri

JANUARY-FEBRUARY 2015

DEMOLITION

EXCAVATORS

componentswith their associated costs. In

addition, because of thismaintenance in the

field is easier.

ThenewLDC eliminates thepossibility

of human error that could affect the stability

of themachine. A tactile colour display

shows diagrammatically thepositionof the

attachment in real time and informs thedriver

of the authorisedmovements that he can

make. Adisplayof theposition (levelness) of

themachine is alsogiven to thedriver.

The increase inworking envelope allowed

by thenew extended reachmeans that

demolitionworks canbe carriedout using

machines of smaller size than at themoment,

whichhas the addedbenefit of reduced fuel

consumptionduringwork aswell as easier

machine transport.

A PERSONAL VIEW

It is unarguable that Ipswich,UK, based

KocurekExcavators havebeenone of the

leadingproponents of high reachdemolition

excavators, withmore than100 suchmachines

havingbeenproducedby the companyover

the years.Duringmost of this time, thepublic

faceof the companyhas beenRonCallan,

whountil recentlyhad the jobof selling

the company’s services.He is nowwinding

downhis time as heheads for awell-earned

retirement. LindsayGale caught upwithhim

recently and talked about thedevelopments

hehas seenover the yearswheredemolition

excavators are concerned.

Over recent times, themaximumworking

Working at home

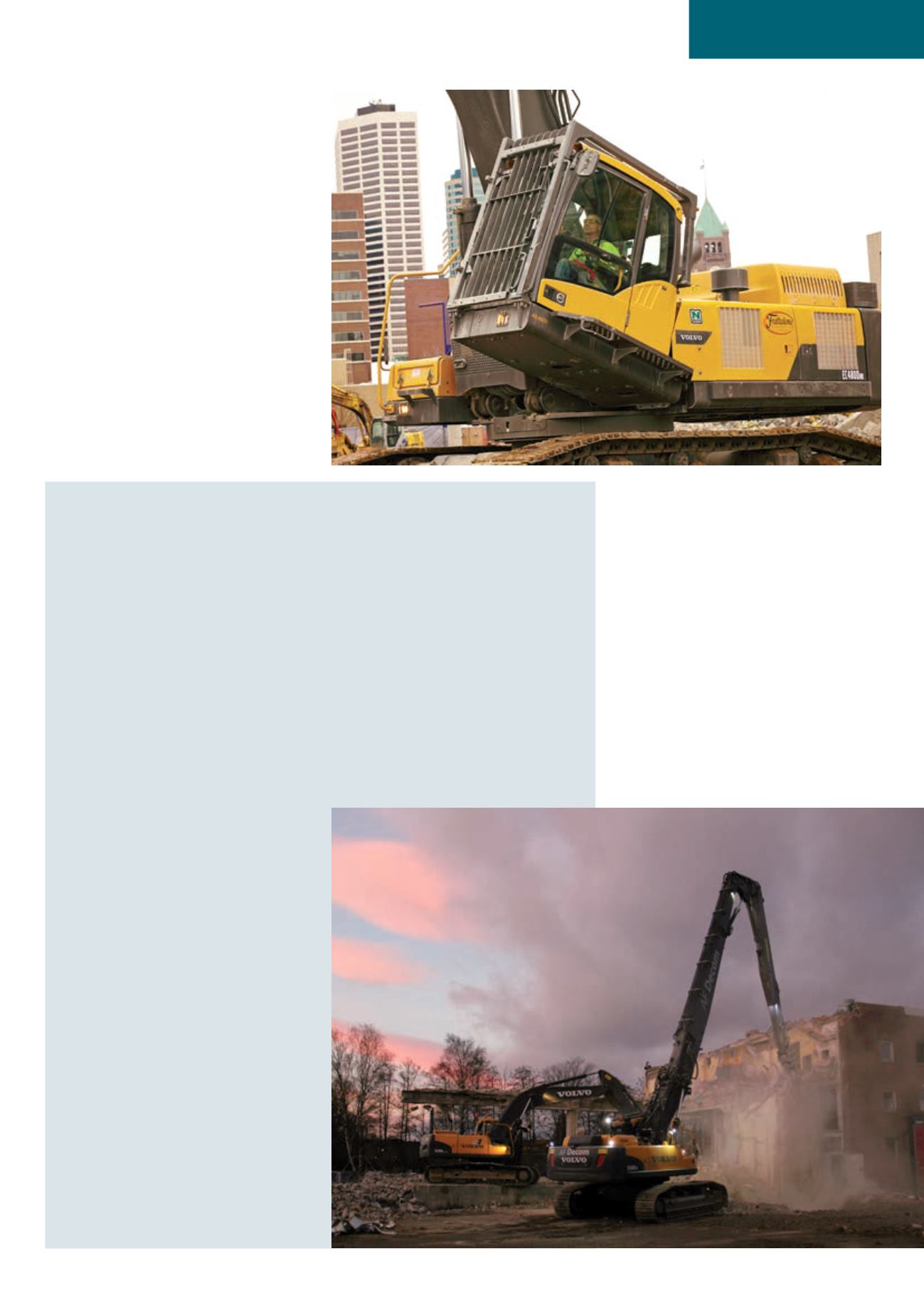

A27m (88.6 ft) Volvo EC460C-Series high reach excavator was rolled into Eskilstuna

in Sweden, site of Volvo CE’s old hardening plant, and slowly drove up to the back of the

building to start demolition.

“With thesemachines it is not just about getting the height,” said David Arnoldsson,

manager of Volvo CE’s special applications solutions team. “It is also about maintaining

machine control and stability at maximumworking height. As little as 10mm of boom

movement at the base of themachine can be over 1m (3.3 ft) of movement at the end

of the arm – so if misused thesemachines have the potential to become unstable. As a

matter of safety, features are fitted to prevent this, such as additional counterweights

and Volvo’s ‘slew angle limitation device’ fitted onto the slew ring that prevents the

superstructure straying outside its safe operating envelope. It is also good practice to try

to keep the superstructure in line with the track frame asmuch as possible tomaximise

stability.”

An additional safety feature is Volvo’s Total Moment Indicator (TMI). Using pressure,

angle and slew sensors this system provides a warning to the operator via an audible alarm

and lamp signal inside the cab if themachine is overloaded.

Unlike othermanufacturers, Volvo CE

fits an additional counterweight beneath

the existing counterweight of the excavator

(5 tonnes extra on the Volvo EC460B ultra

high reachmodel), as it is easy to fit and

remove, does not impede rearward visibility

or increase the slew radius at the rear

of themachine, which canmake it more

vulnerable to damage when slewing in

confined areas.

In the cab, the user has a choice of

foot pedals or joystick/buttons to operate

rotational or hammer equipment. Unlike

in excavation duties, high engine speed is

often not always a priority in demolition

applications. As a result, engine speeds

can be lower - just sufficient tomaintain

hydraulic flow to the attachment. Operators

are also assisted in seeing what is going

on at height by a camera fitted on the far

end of the boom that gives a view of the

attachment and also a spray system that

dampens the work area, acting as a dust

suppressor. Another option is a tilting seat

and console arrangement that helps to

prevent operators incurring neck or back

problems.

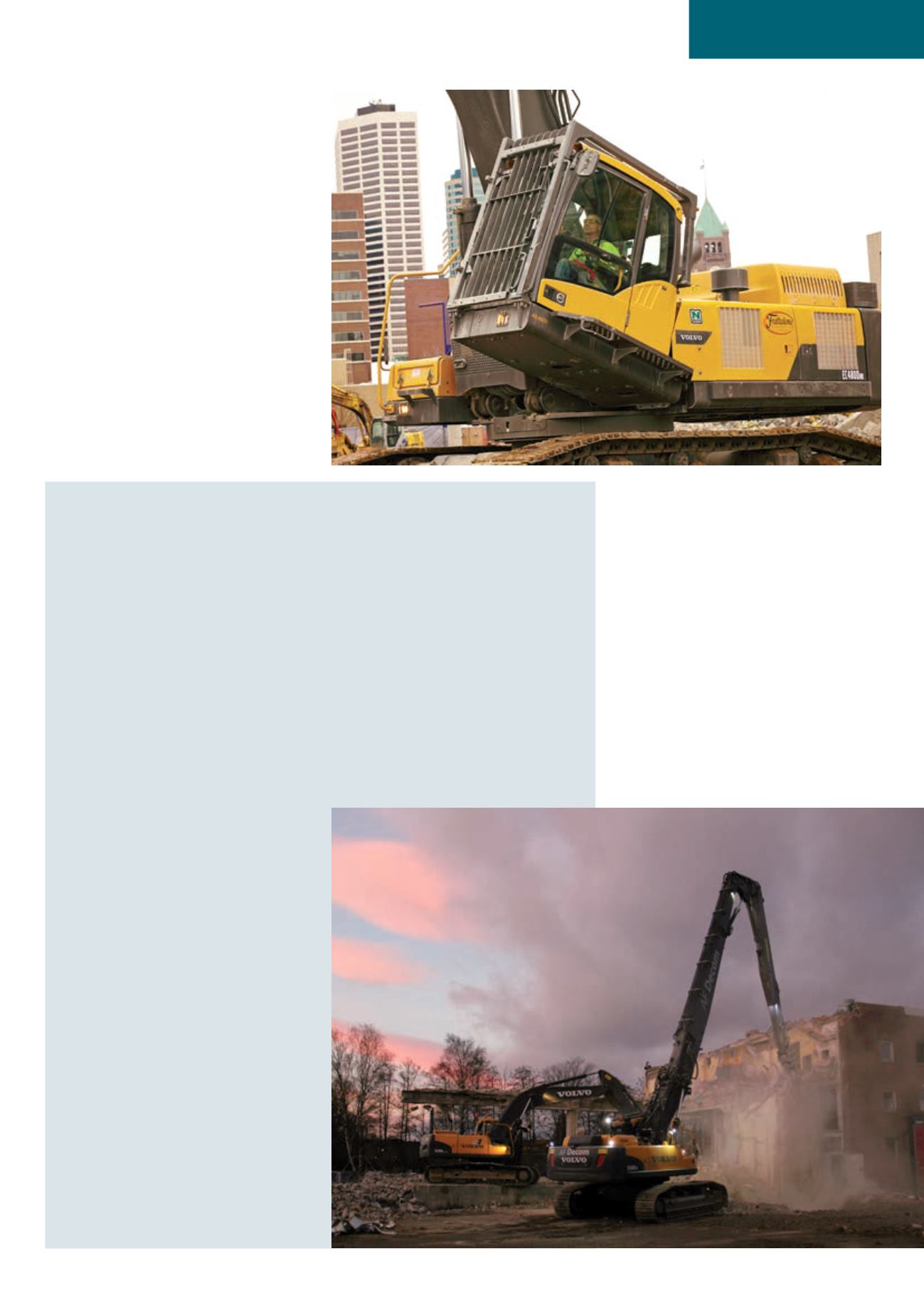

A heavy duty Volvo EC480D-Serieswas purchased

by US contractor Frattalone Companies to

demolish the oldMetrodome stadium in

Minneapolis. The boom connect system on the

machine allows themachine to be switched from

standard dig to high reach configuration