10

JANUARY-FEBRUARY 2015

d

&

ri

DEMOLITION

EXCAVATORS

will have its latest largehigh reach, the

PC490LC-10. Komatsu ismaking this

machine availablewith twodemolitionboom

configurations. Inmedium reach, with a

boom extension fittedbetween the standard

digboom and theboom foot, themachine

weighs in at 65.95 tonnes, can reach to17.4

m (57 ft) and can carry a 5 tonne tool to

that height.With its fullydedicatedhigh

reachboommounted to theboom foot, the

machinewillweigh in at 65 tonnes, reach to

28m (92 ft) and carry a toolweight of 3.35

tonnes (including anyquick coupler system).

Themodel

thatwill be

seen inParis

will in fact

bepowered

by a Stage

IIIB/Tier 4

Interimdiesel

but

D&Ri

understands

that in the

future Stage IV

versionswill

be available.

Komatsu

also says that it fully supports theuse of

hydraulic breakerswhen themachine is in its

medium reach configuration.

Power comes from a six cylinder

KomatsuSAA6D125E-6-A common rail

direct injection, water cooled turbocharge

and after cooleddiesel developing270

kW (362hp) at 1,900 rpm. Themachine

comeswith the company’s Safety Space

Cab that tilts for optimum viewover the

attachment duringoperations. The cab also

features anewWorkingRange Indicator,

developed specifically for themachine that is

programmed for usewithboth configurations

and can storeup to15 toolmemory settings.

Liebherr is another thatwill have anew

demolition specificmachine at theParis show

ground.However, the company is notwilling

Getting a grip

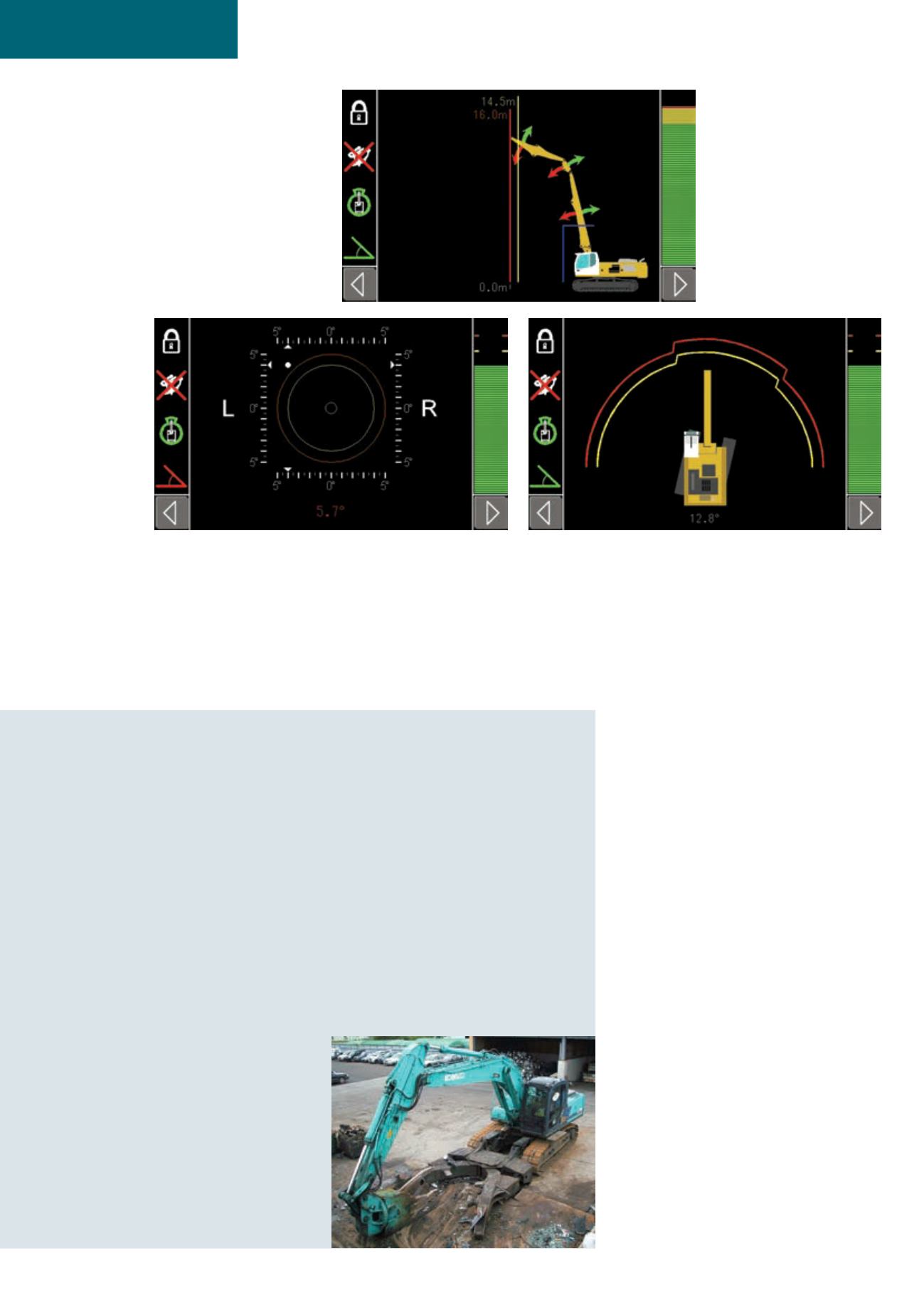

While strictly speaking not a demolition excavator, we felt that Kobelco’s SK210D is

sufficiently interesting to be included in this feature. Designed for a very specific application,

namely automobile dismantling, as the picture shows themachine features a clamp

arrangement mounted to the undercarriage and a boom-mounted crusher.

Components, e.g. intricate strands of wiring harness, can be removed from a vehicle’s

chassis by themulti-role crusher that features jaw-like pincers attached to themain

operational arm. The crusher unit is operated via a proportionate control button on the

joystick. The fully rotational crusher head can rip, tear and crush withmore than adequate

delivered hydraulic torque.

To assist dismantling, the SK210D features the company’s fast two-way Clamp Arm. This

allows the crusher to gain purchase and dismantle/crush while holding the object firmly.

Stripping and bending tools are also located on top of the clamping arms.

Operator safety is further enhanced on the SK210Dwith the fitting of a protective front

and upper window cage as standard. Excellent fuel economy and low noise output are also

typical Kobelcomachine attributes.

According to the company, the SK210Dwould be suitable for any other application where

precise dismantling and component removal

is required.

On a separate note, there is still no

word on when, or even if, Kobelco plans to

introduce its demolition excavators into the

Europeanmarket A company spokesman told

D&Ri

: “the Europeanmarket for demolition

excavators is a competitive one and Kobelco

therefore currently does not bring these

machines into the region – this decision will

be under continuous review of course and

we cannot rule out their introduction at some

time in the future.”

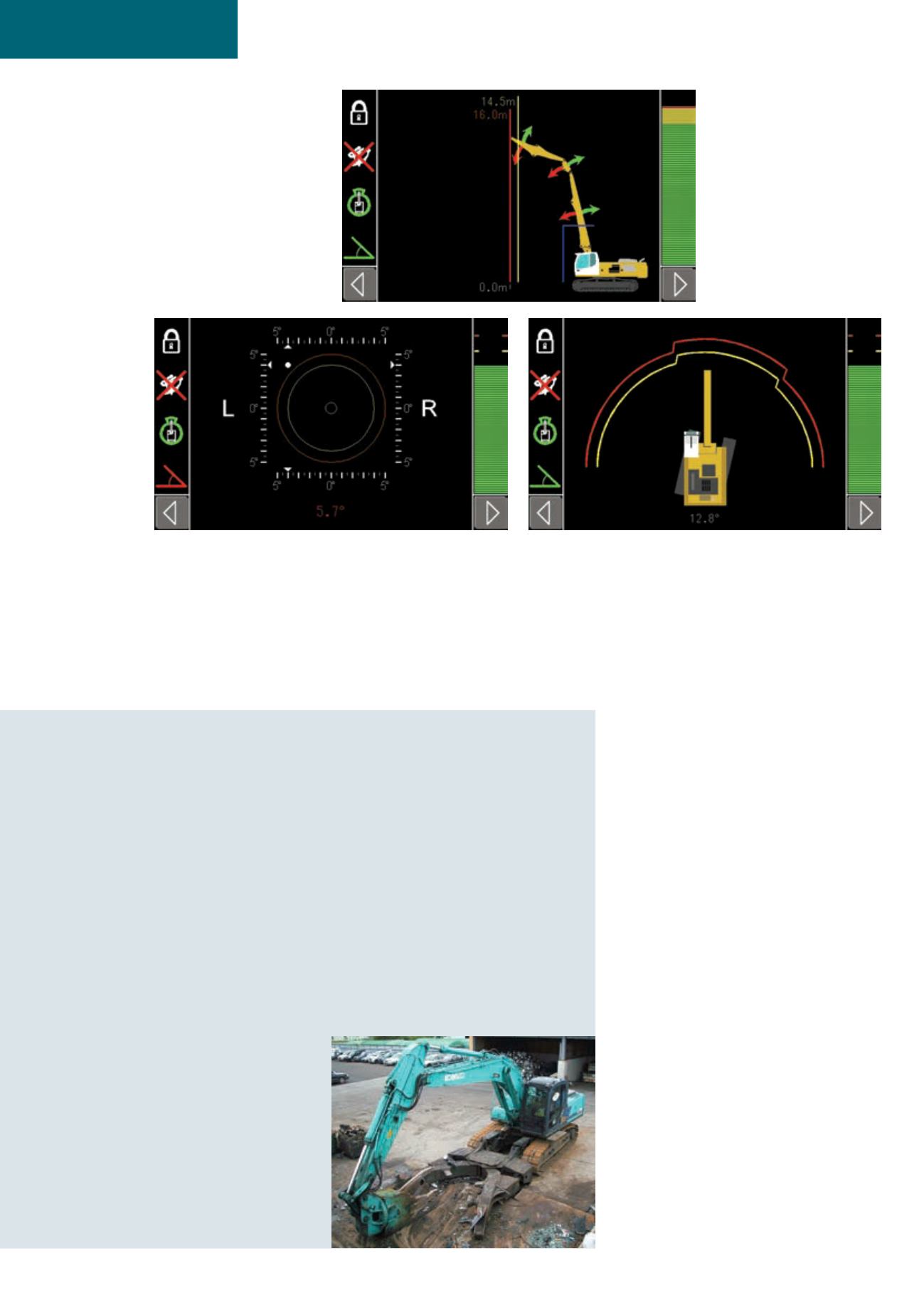

The displays that the operator

sees in his cab from the new

Liebherr Demolition Control

system

to share anydetailed information at this stage

butwehope tobe able to reportmore fullyon

themachine in the Intermat showguide that

will be inourMarch-April issue, although

there arehints to it below.

IN CONTROL

Nevertheless, we candiscuss one feature that

themachinewill carry– thenewLiebherr

DemolitionControl (LDC) system thatwill be

fitted to its new excavators.

Liebherr-France SAShas had anLDC

system for anumber of years, but the system

thatwill be on show is all-new, says the

company. This system allows the operator

toknow thepositionof thedemolition

attachment at any time and toguarantee the

stabilityof the excavator. Bymeans of angle

sensorsmountedon the excavator andusing

automatic recognitionof the attachment

lengths, the systemgives continuous

information about thepositionof the

attachment (in cm). Byknowing theweight of

the tool the excavator canoperate in complete

safetywithin themachine'sworking envelope.

According toLiebherr, themain challenge

was to find a solution to integrate this LDC

system into the electronics of the excavator

and to simplify the functions for theoperator.

The solution thatwas developed

automatically recognises attachment lengths,

and angle sensors areused tomonitor the

positionof the equipment and to integrate the

tool typeswith theirweights into thedisplay

on the excavator. Tooptimise theperformance

of the excavator, extended reachwith rotation

limitationhas alsobeendeveloped. This

extended reach allows the operator to cover

a greaterworking area, which results in a

productivity gainon site.

Because theLDC is integratedwith the

on-board electronics on the excavator there is

no requirement for additional LDC-specific