41

CONSTRUCTION EUROPE

SEPTEMBER 2014

COMPACT LOADERS

so it is possible to work at almost idle. Low

level of noise is a big advantage for early

morning tasks.”

He added, “Kohler has invested a large

amount of money into the development of

this new engine. For our part, we have built

our own, well-functioning product around

this innovation.”

Low emissions – and consequently low fuel

consumption – are achieved by using a high

pressure common rail fuel injection system,

turbocharger, intercooler, cooled exhaust gas

recirculation (EGR), four valves per cylinder

technology and a diesel oxidation catalyst

(DOC) within the exhaust system.

Even though the engine output has

increased by almost 20% and torque by over

40%, the fuel consumption has decreased by

over 20%, said Avant.

Avant claimed other improved features

for the 760i compared with the Avant 750.

Maximum drive speed of the Avant 760i is

30km/h and auxiliary hydraulics maximum oil

flow is 80 litres/min, which it described as a

significant development.

Tyre size is also larger, both in diameter and

in width, to improve handling - especially at

higher drive speeds, and to decrease pressure

when driving on ground with lower carrying

capacity and on sensitive surfaces.

MORE POWER

Case Construction Equipment has updated its

skid steer loader and compact tracked loader

ranges to offer more engine and hydraulic

power.

There are 10 compact models – seven skid

steers and three tracked loaders – which are

said to deliver improved efficiency through

the use of environmentally-friendly Tier 4

engine solutions, providing customers with

increased power and torque and reduced

operating costs.

Case is offering an upgraded small-frame

model, the SR160 to replace the SR150, which

is one of the company’s best-sellers. The

new model has a larger and cleaner engine

claiming up to 15% more power.

The smallest, SR130, is now powered by

a 2.2-litre 36kW Tier 4 Interim engine, that

uses internal cooled exhaust gas recirculation

(CEGR) without the need of additional

particulate filters.

The mid-range SV185 and SR175 skid steers

are powered by Tier 4 Final engines. Case

said that through the use of a turbocharger

and high-powered common rail fuel

injection with electronic control, there was

no requirement for regeneration on these

engines. A maintenance-free diesel oxidation

catalyst (DOC) system enables compliance

with stringent regulations.

Similarly the SR200 and TR270 machines

that use a 54kW turbocharged engine can

meet Tier 4 Interim without regeneration.

The most powerful SR250, SV300, TR320 and

TV380 models all use a 66kW turbocharged

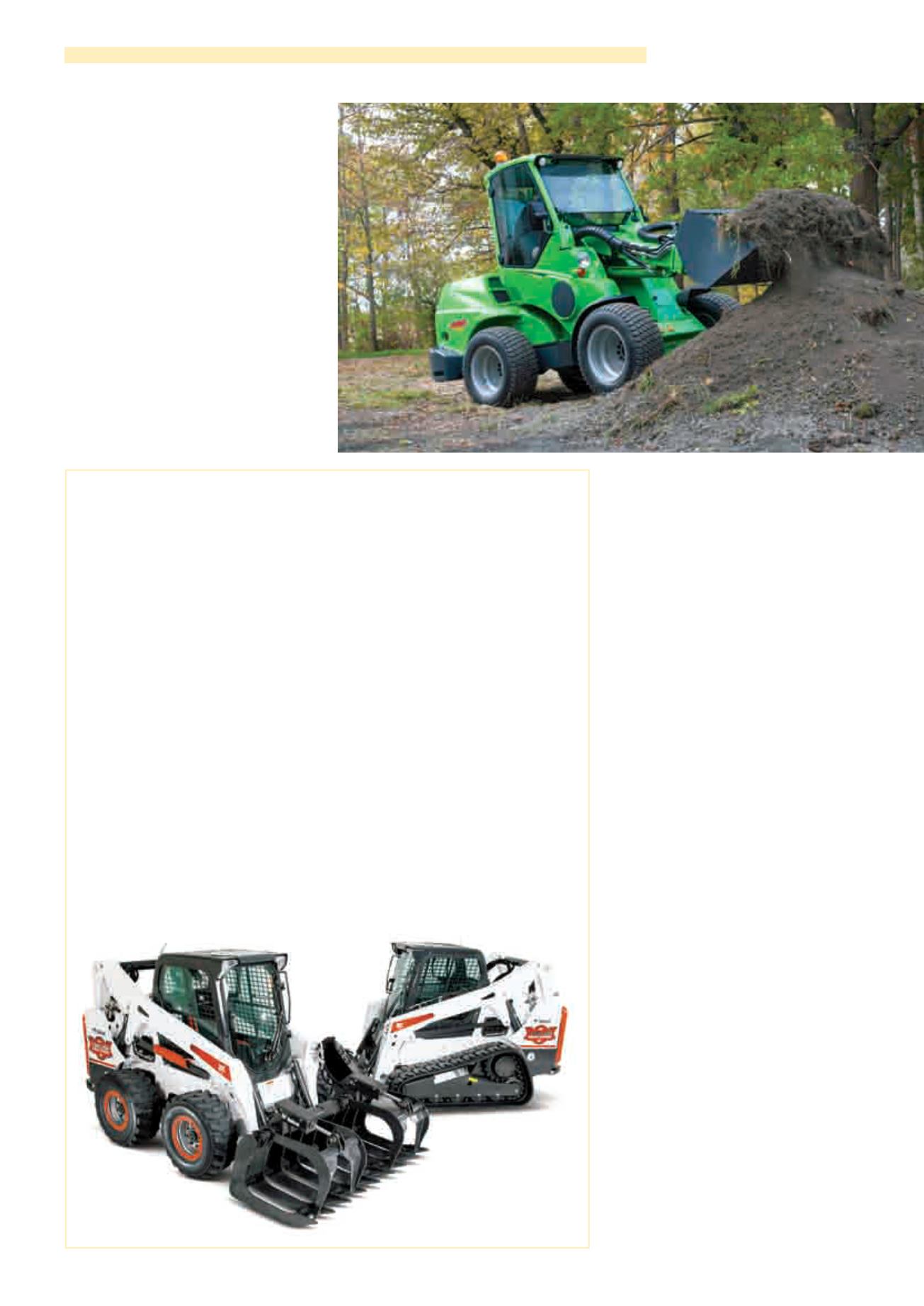

Limited special edition Bobcats

As part of events worldwide this year, the 2014 Bobcat Convention in Prague in the Czech

Republic at the end of May saw the start of celebrations in the Europe, Middle East and Africa

(EMEA) region to celebrate production of the company’s one millionth compact loader.

It claimed to be the company that created the compact plant industry in 1958 with the

development of the original three-wheeled Keller loader, the predecessor of the Bobcat skid-

steer loader.

Martin Knoetgen, EMEA president of parent company Doosan Construction Equipment,

said, “It took Bobcat 43 years to produce the company‘s 500,000th compact loader, but it has

taken just 11 years more for the company to add the second half million loaders.

“One million loaders is a very important milestone for Bobcat, representing many things,

including more than 50 years of leadership, commitment and innovation at the head of the

compact equipment industry, which is encapsulated in every Bobcat product sold today.”

To celebrate the landmark, Bobcat is offering new Special Edition Millionth Loader machines,

based around the company’s successful S650 skid-steer and T650 compact loader models.

As well as special look, the Special Edition Loaders incorporate additional features that are

not found on other Bobcat machines and are available in limited quantities from Bobcat

Authorised Dealers throughout EMEA during 2014.

Among the extras are cushion lift cylinders; a two-tone air ride Millionth Loader Seat; a two-

tone interior; a commemorative logo on the start-up screen and a new intermittent wiper

system.

After purchasing the rights to the Keller Loader in 1958, Melroe Manufacturing, the

forerunner to Bobcat, developed the design, and in 1960 launched the M-400 model, which,

with its four-wheel-drive, claimed to be the world’s first true skid-steer loader. In 1962, Melroe

introduced the M-440, an improved version of the M-400. A Melroe associate suggested that

the loader be called a Bobcat in honour of the prairie animal which is “tough, quick and agile”.

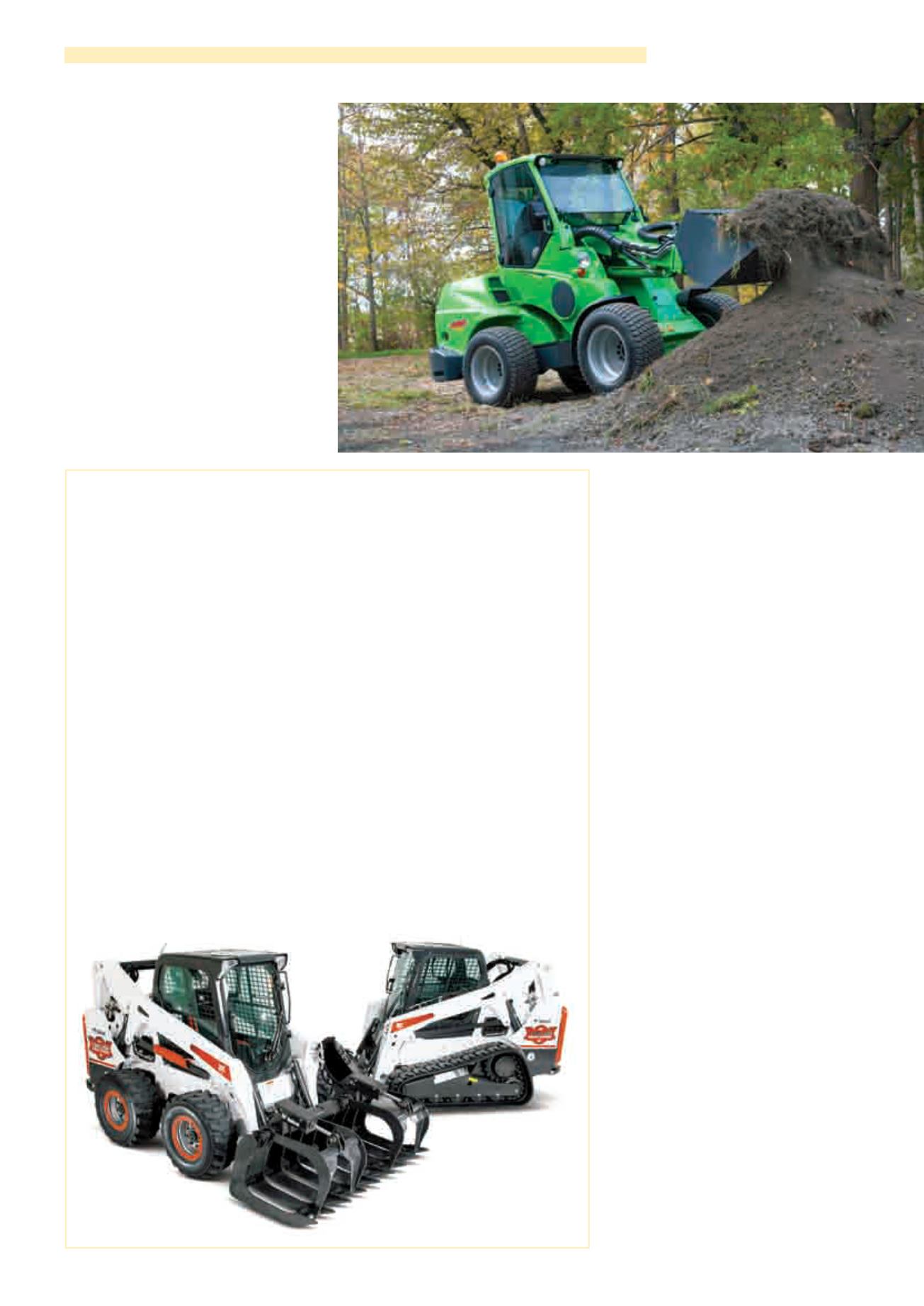

The 760i is the biggest, fastest and most

powerful loader in the Avant range