34

CONSTRUCTION EUROPE

SEPTEMBER 2014

FOUNDATIONS

Munich project

Foundations specialist

Bauer is working on a

high-profile job not far

from its headquarters

at Schrobenhausen

B

avarian-based Bauer is working

on a number of large projects in

Munich, Germany, including a major

development at Schwabinger Tor on the site

of a department store and an old Holiday Inn

hotel building.

When finished, the site – described as an

“urban quarter” – will contain a hotel, plus

apartments, offices, shops and a theatre.

Preliminary work started in 2011.

Bauer, based at Schrobenhausen some 80km

to the north, has been working on a site

which is basically a hole in the ground that is

approximately 75m x 350m. The company said

that while it was not a particularly large site,

it was a prestige position at the entrance to

Munich from the north.

VARIOUS TECHNIQUES

Florian Bauer, a project manager with the

company,saidthatvariousdifferenttechniques

were being used at the Schwabinger Tor site.

On one side, secant pile walls have been used,

with Bauer’s ground anchors – invented by the

company in 1958.

The other walls are constructedby themixed-

in-place (MIP) method, which the company

said it had developed to avoid the need for

labour-intensive transport, and to cut costs,

reduce emissions and therefore to create less

disruption for residents. It is often used to

stabilise dams and similar constructions.

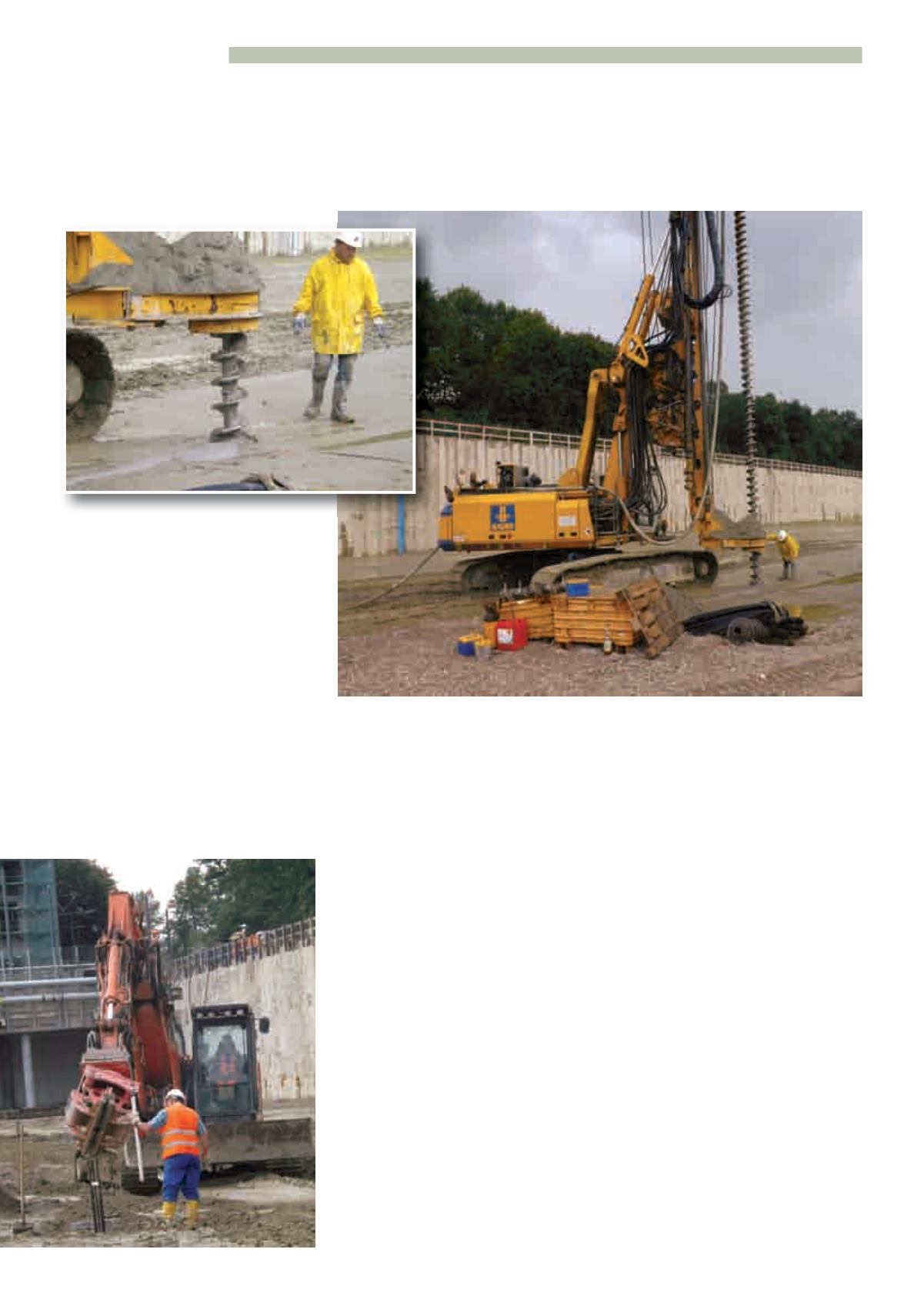

The MIP technique involves a mix of

bentonite, cement and water. The soil is

broken up with a single or triple auger, and

the mix is added. Bauer said that with Munich

built mainly on gravel, this mixed with the

other constituents to produce what was

effectively concrete.

The MIP walls are also tied back with anchors

because of the close proximity of a road and

a tram line.

Bauer said it would be more usual to use MIP

all round, but a former fuel station left some

ground contaminated by diesel.

Piles are being sunk on the floor of the

site, which is down to clay, and water has to

be continuously pumped out. A Bauer BG

18H drilling rig and a Hitachi Zaxis 225 USLC

excavator are used. The rig creates a hole,

which is filled with cement. The excavator

picks up the rebar and pushes it in, before

tapping it down to the carefully measured

required height.

Bauer said that the company chose the

technique to suit the individual project,

and that there could be many variations on

one site, including temporary or permanent

anchors, sheet piles, shotcrete and others.

Bauer said, “Drill rigs can be custom made.

We talk to our customers.”

Examples of this are some “very customised”

products that have been used in an

underwater deep drilling site in the North of

Scotland.

“We do piles for wind turbines that not

everyone can do,” he said. “We make many

one-off machines.”

ce

At Schwabinger Tor, the Bauer drilling rig digs and fills the resulting hole with cement

The rebar is placed in the hole to

a set depth

The floor of the jobsite at Schwabinger Tor

is clay, and water has to be pumped away