32

CONSTRUCTION EUROPE

SEPTEMBER 2014

FOUNDATIONS

project in Hampshire, UK.

Tensar

International’s

TriAx

soil

reinforcement system has been brought in to

overcome challenging ground conditions at

England’s largest wind farm site. It provided

a multi-directional geogrid product for the

construction of 24km of access road for the

Keadby wind farm site, in North Lincolnshire.

Bilfinger’s steel test

Bilfinger has been awarded a €20 million contract to test steel foundations for the Wikinger

offshore wind farm project in the Baltic Sea on behalf of Spanish energy supplier Iberdrola.

Work will begin this autumn when Bilfinger will drive steel piles up to 38m long into

the seabed at the future location of the wind turbines. Tension and pressure tests will be

conducted underwater following a static period of several weeks. The findings will assist in

the development of a technically- and economically-optimised foundations solution for the

wind turbine.

In addition, Bilfinger will test noise protection systems for the client, which will help reduce to

a minimum the noise pollution that marine fauna is exposed to during the construction phase.

Work on the Wikinger offshore wind farm will begin in 2016, and will see a total of 70 wind

turbines installed in water depths of up to 42m north east of the German island of Rügen.

Joachim Enenkel, member of the executive

board at Bilfinger SE, said, “The project is

an important step forward for our offshore

business – one that will further expand

our leading technological position in the

construction of foundations for wind turbines

on the open seas.”

In recent years, the group has delivered

the foundations for a large proportion of the

wind farms built in the North Sea and Baltic

Sea. The foundation work for Dan Tysk in the

German North Sea was completed in 2013,

and in 2012 the company also concluded

work in the UK for London Array in the

Thames Estuary.

Bilfinger completed an

offshore foundations

project at London

Array last year

a double rotary, which allows casing and the

drill string to be advanced independently.

PILE DRIVING RIGS

Meanwhile, Finnish piling specialist Junttan

has added three new units to its X-Series pile

driving rig family. The new models, carrying

the nickname J-reX, are the PMx26, PMx27 and

PMx28. They have maximum leader capacities

of 20, 23 and 25 tonnes and maximum pile

lengths of 24m, 25m and 28m.

Junttan has redeveloped the whole basic

structure and component layout of its

X-Series for the PMx26-28 machines, including

overhauling the hydraulic system, to make the

machines more economical. The pile drivers

also claim to have reduced emissions.

UK piling contractor Suttle Projects has

increased its drilling capabilities with the

purchase of a new Klemm KR709-2.

Suttle Projects had been using a second-

hand Klemm KR708-2, which it had purchased

to enable it to expand into augured piling

as an alternative to driven piling. However,

increased demand for its services – partly

due to its rail infrastructure work for the UK’s

Network Rail – meant that a solid investment

was required. The new Klemm KR709-2 will

enable Suttle to drill to greater depths in a

single stroke, speeding up the piling process.

The Klemm KR709-2 is suitable for medium

weight drilling requirements and is capable

of 450mm to 600mm holes. Suttle has already

had the new unit out at work, using the drill

rig during pre-auguring for sheet piling in a

Two Liebherr LB 44-510 rotary drilling

rigs are creating the foundations for

the international particle accelerator in

Germany

SR-75 is a 70-tonne class rig mounted on a

variable gauge undercarriage with telescopic

side frames complete with predisposition for a

casing oscillator.

The electrical system has been simplified and

located into a single panel and all the electrical

connections are provided with harness cable

and LED signal. Its simplified structure is said

to allow a fast transformation between CCS

(continuous circulation drilling system) and

WCS (winch crowd system) versions.

The SR-75 offers a 293kNmmax rotary torque

value and a pull-up force of up to 281kN for

CCS and 408kN for WCS.

Third in the new Soilmec line-up, the SM-17

multipurpose drilling rig is suitable for micro

drilling and anchoring. The SM-17 is fitted with

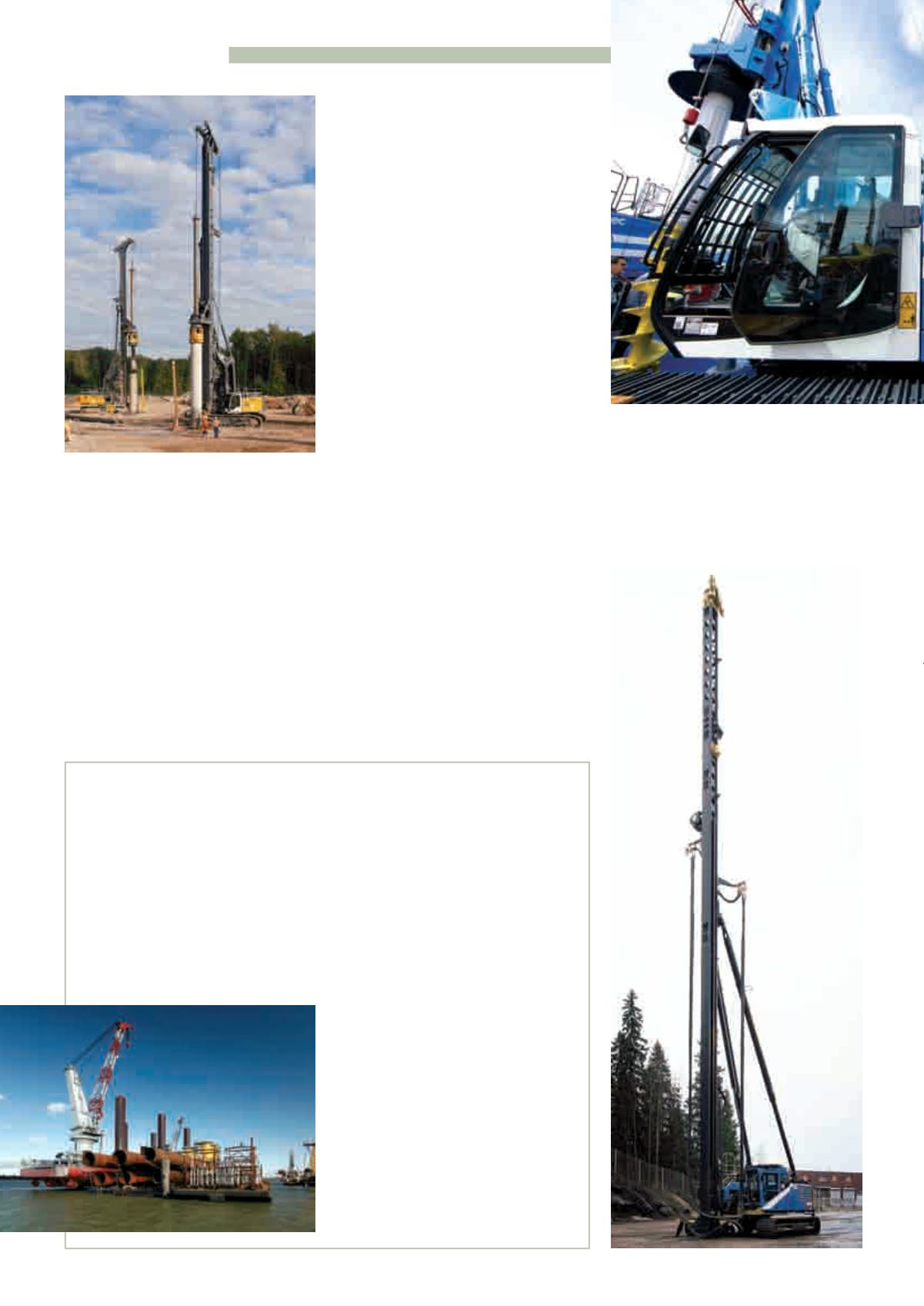

Junttan’s

new ‘J’-reX’

pile driving

machines offer

a new hydraulic

system and

increased fuel

efficiencies