FOUNDATIONS

31

CONSTRUCTION EUROPE

SEPTEMBER 2014

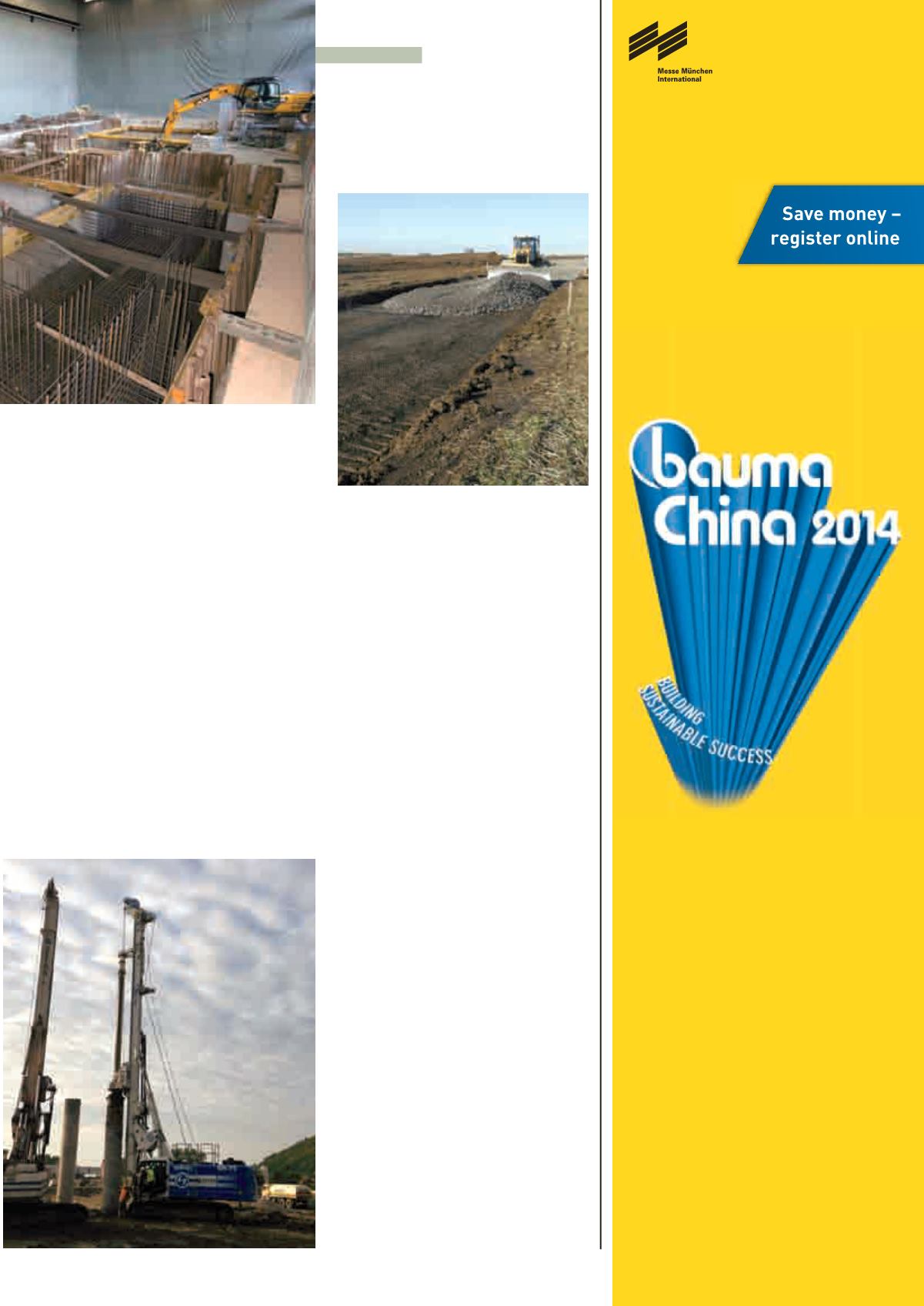

Equipment from two specialist Groundforce

divisions was brought in to help with the

installation of a new horizontal boring

machine within NAMRC’s existing facility at

Waverley Technology Park in Sheffield. The

new machine is believed to be the largest of

its kind in a research facility in Europe, and is

capable of manoeuvring work-pieces of up to

100 tonnes in the chuck.

The bases required to support this massive

machinewere constructed ina large excavation

using more than 1,200m

3

of concrete and 100

tonnes of steel reinforcement.

The concrete foundations are supported by

78 auger-bored concrete piles, each 600mm

in diameter and spaced at 2m centres. These

were drilled from the underside of the existing

floor slab level before work started to excavate

the surrounding material.

Groundforce Shorco supplied the support

system, which comprised the company’s Mega

and Maxi braces with 900 Series braces of

varying lengths. Groundforce’s HY6 trench

sheets were used to line the excavation while

Piletec supplied a MS4 EMV piling hammer to

install them along with a Taets pile breaker to

cut down the concrete piles to the required

length.

ROTARY DRILL

InGermany, Liebherr has seen its newLB44-510

rotary drilling rig used on the construction of a

particle accelerator in Darmstadt.

Two LB 44-510 rotary drilling rigs are being

used on the construction of the international

particle accelerator FAIR (Facility for Antiproton

& Ion Research). The drilling rigs are there

to stabilise the subsurface with cast-in-place

drilled piles. The job will see 1,400 piles,

measuring between 40m and 62m, set in the

ground. FAIR will begin operating in 2018.

The latest development in Liebherr’s range

of deep foundation products, the LB 44-510

rotary drilling rig offers a torque of 510kNm.

In kelly drilling applications, it is configured

for drilling diameters of up to 3m and depths

of up to 92m. The drilling rig weighs some 170

tonnes and is powered by a V8 diesel engine

offering 505kW and complying with the Stage

IIIB emissions standard.

Italian manufacturer Soilmec launched three

new drilling rigs earlier this year, all designed

to meet new emission standards.

The SR-45 and SR-75 hydraulic drilling rigs

are designed for large diameter drilling of

cased or uncased bore piles, CFA piles, cased

augured piles, displacement piles and Turbojet

piles. The two rig types feature a re-design of

the mast, rotary, kelly and parallelogram. This

helps with the forward weight balance of the

machine, providing enhanced stability, greater

crowd and extraction force, and increased

depth capability.

The largest of the new Soilmec rigs, the new

The Groundforce teams working on

the Nuclear Advanced Manufacturing

Research Centre foundations have created

a concrete foundation supported by 78

auger-bored concrete piles

Tensar International provided its TriAx

multi-directional geogrid product for the

construction of 24km of access road for

the Keadby wind farm site

Soilmec’s new SR75 hydraulic drilling rig

working on a job site in Turkey

November 25–28

SHANGHAI

NEW INTERNATIONAL

EXPO CENTRE

7

TH

INTERNATIONAL TRADE FAIR FOR

CONSTRUCTION MACHINERY,

BUILDING MATERIAL MACHINES,

CONSTRUCTION VEHICLES

AND EQUIPMENT