CRANEACCIDENTS

assumptions takenwhen the load

chartwas calculated, or reduce thevalue

of thepermissiblewind speed for the lift.

This important information isneeded

before lifting lightweight loadswith large

sail areas.

The reasonbehindmost turbine

erectionaccidents is insufficient planning

and/or a lackof knowledge, especiallywhen

lifting rotor assemblies. There

have alsobeena lot of accidentswhen

semi-assembled cranes aremoved from

one erection site to thenext.Cranes

can topplewhiledrivingbecauseof an

insufficient loadbearing capabilityof the

road.Most, or at leastmany, roads leading

to turbine erection sites aredesigned for

anaxle loadof 16 tonnesbut,whena large

crane ismoved in the semi-assembled

configuration, axlepressure canbewell

beyond25 tonnes.

Inaddition, toooften it is forgotten

that besides thehigh loads imposedunder

thewheels, the centreof gravity is at a

significant height. Thisheightmight be the

sameor evenmore in comparison to the

support baseof thewheels, or the support

base at the suspension cylinders, in case the

suspensiongivesway.A centreof gravity

severalmetresup in the air for apartially

erected crane isnot unusual. Thehigher

the centreof gravity, themore the crane

reacts to imperfections in the road.When

the centreof gravitymovesover the tipping

line, for example, due tounevenground,

the cranewill tipand there is absolutely

nothingkeeping it from tipping, unless the

outriggers areout and theoutriggerpads

are sliding just above theground.

Manyaccidentshappenduring routine

jobs and,moreoften thannot, noplanning

isdoneprior to the crane arrivingon the

site. Theoperatorhasdone similar jobs

over andover again, and it isherewhere

wehave themajorityof crane accidents.

Wevery seldom see accidentshappening in

well planned jobs.

Precisedetails

Planning isnot always easyand, especially

duringdemolition jobs, it canbe extremely

difficult to calculate the correctweight

of the load that youwill endupwithonce

it’s cut loose.

Careful planning isneededprior to each

and every jobandall knowledge from

prior accidentsornearmisses shouldalso

be included.

Planning is important, and failing to

plan isplanning for failure. Thewhole

process shouldbewhat is calleda

A telescopic boom that bent after it hadbeen

repaired. The customer acknowledged that the

previous repairmight havebeen insufficient and

yet refused for it tobe repairedby theOEM

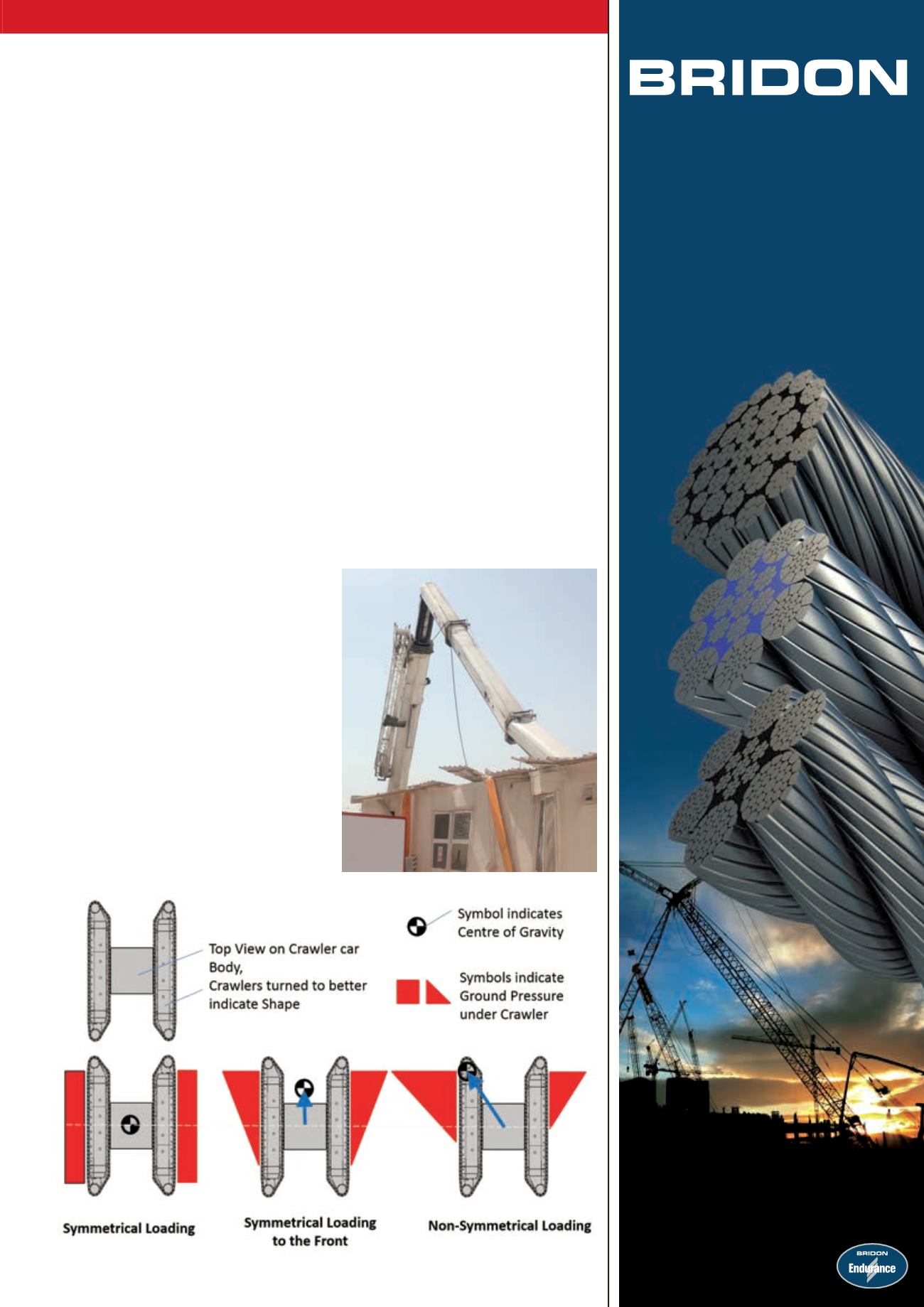

Figure 1: Howa load is distributed strongly

depends on thepositionof the centreof

gravity in relation to the crawler tracks

>

Global technology leader

in themanufactureof wire and rope solutions for

theworld’smost demanding applications.

Our superiority reliesoncontinuous innovation,

qualityassuranceand technical expertise throughout

theorganisationandalong the supplychain.

Delivering lastingsolutions

UnitedKingdom:

Tel:+44(0)1302565100,

USA:

Germany:

Tel:+49(0) 20980010,