22

NOVEMBER-DECEMBER2014

d

&

ri

DEMOLITION AWARDS

environmentally sensitive area, with the

primary focus of the sensitivitybeingdust

leaving site and entering theneighbouring

town. ThroughoutADS’sworks the site

remainedunder continuous surveillance for

fugitivedust leaving the site. Zerobreaches

were reported for theproject.

Dryer 2801 sat on topof 18m (59 ft)

concreteplinths andhadbeen redundant

formany years.Due to its height and

access restrictions, the corroded condition

andoverallweight of thedryer drumwas

andweighing each end togive amuchmore

accurate totalweight of 89 tonnes. This

allowed theuse of a local 500 tonneGrove

mobile crane to lift and lower thedryer

drum inone section. The lengthof thedryer

requiredADS tohireAustralia’s largest

spreader bar and the liftwent offwithout

incident.

Significant corrosionover timemeant that

the bins and conveyor systems had restricted

access. The corrosion impactedwalkways

andhandrails,making it unsafe toutilise

anyof the existing access routes. Allworks

was undertaken through theuseof elevated

workplatforms. ADSprogressively separated

bins and individuallydeveloped engineered

tripplans, according towhich strategic legs

were cut to enable eachbin tobe tripped and

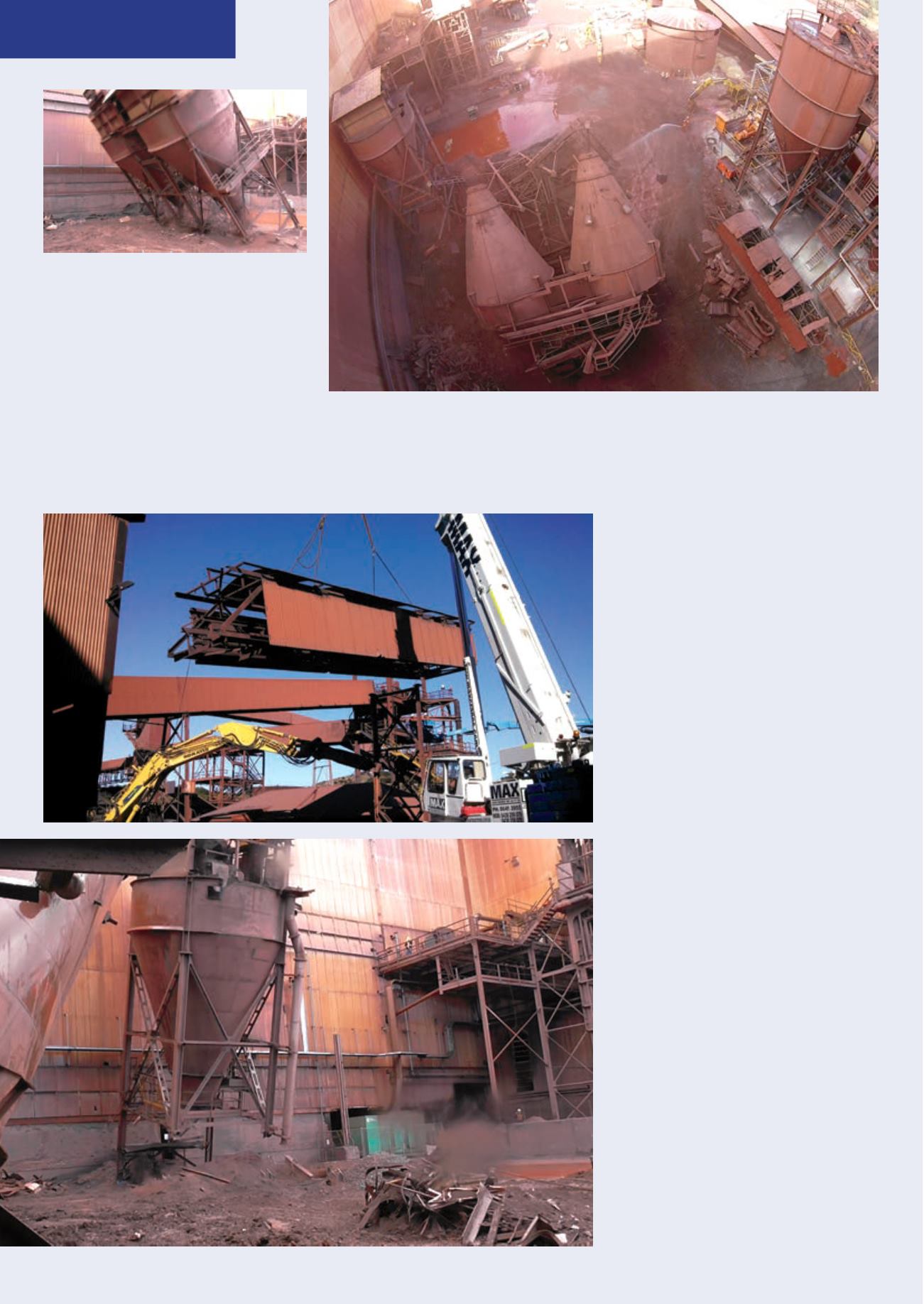

processedonground. Conveyor gantrieswere

pre-cut and then attached to secured lifting

points and an appropriate sized crane, with

final cuts thenbeingmade and eachgantry

lifted and lowered to the ground and then

processed into scrap. Thiswas then loadedout

inheavy transport vehicles off site.

Motors andgearboxeswere carefully

salvaged at the clients request andwill be

re-usedwithin theoperational site.

Thedryer concreteplinths and thedryer

rollinggear had tobe removed -ADS’s 90

tonne Jewel front end equippedhigh reach

excavatorwith ahydraulicpulveriser/shear

processed theplinths toground levelwithout

incident - theheight and the closeproximity

of theplinths to the operatingplant required

the additional reachof thismachine to

ensure theprocess occurredunder controlled

demolition conditions.

Walkways leading to areaswhereplant

hadbeen removedhadhandrails installed

andopenings re-cladded andmade safe. The

operational sitewas only required to cease

operationalworkswhile the large crane lift

of thedryer occurred. At all other times

workswereundertakenwithin the company’s

exclusion zonewithin theoperating sitewith

no incidents.

At peak, aworkforceof 15was deployed

to carryout theworks, operating in a single

shift. In all theworkgenerated750 tonnes of

scrap steel and1,500of concrete, all ofwhich

was recycled.

■

Pellet plant storage siloswere brought down and

then processed on the ground

unknown.

ADS’s engineers calculated theweight

of thedryer sincewithout accurateweights

the crane size requiredwouldneed tohave

50% safety capacity added. ADSovercame

this challengeby jackingup thedryer drum