18

NOVEMBER-DECEMBER2014

d

&

ri

DEMOLITION AWARDS

Thedemolition specificationonly

permitted theuseof one entranceonto site. In

normal circumstances a site entrancewould

usuallybe formedwhere the façades arenot

being retained.However, in this case thenon-

retained façadewasdirectlyoppositeTCEs

offices, so theonlyotherpositionavailablewas

along theNBS façade throughan existing shop

front.

ALLOWINGACCESS

Following swept pathanalysis of the types of

constructionvehicles required to service the

project, the shop front at 4NBSwas selected

as theonlypossibleusable entrance. To ensure

this locationwouldwork, furtherdetailed site

investigationswereundertaken to establish

the constructionof thebasement andground

level structure.Keltbray’s temporaryworks

engineersprovideda scheme that involved the

installationof over 300acrowprops to support

the existingground floors, installing150m

2

(1,615 ft

2

) of steel plates toprotect the existing

ground floor, installationof a temporary

bridge structure spanning the existing light

well between thepavement and shop front and

finally the excavationand constructionof a

concrete slab (crossover) toprotect the existing

serviceswithin thepavement.

With the abovekeyworks complete, the

site teamwere able to takedeliveryof theplant

toundertake the first element of demolition

to the rear low level courtyard structures.

However,witha restrictedheight clearanceof

3.7m (12.2 ft), the type and sizeof plantwas

limited.

Inaddition to the site constraints,NBSwas

reduced toa single carriagewaydue toanother

construction sitebeingdirectlyopposite

usingapit lane to service that site. From the

offset agreementswereput inplace to ensure

the sectionof thepit lanedirectlyopposite

theKeltbray site entrancewas kept free at all

times allowingaccess/egress toW5.However,

to ensure these agreementsweremaintained,

weeklyanddaily coordinationmeetingswere

heldbetween the site construction teams.

Once the low level demolitionwas complete

the site team could focus on thenext key

resources for the successful deliveryof the

project, thedemolition tower crane and the

foundations for the façade retention system.

The tower cranewasdesigned tobe free

standing,with coverageover thewhole site. In

planning the tower crane erection,Keltbray

andHTCwere restricted toonlyusingNBS

for thepositionof the erectingmobile crane.

Thepositionof thiswithinNBS alsohad

to contendwith the external scaffoldand

hoardingof theW4project, so the erecting

mobile crane selectedwas a250 tonnewith fly

jib to reachover the existingbuildings. The

foundations for the façade retentionwere all

designedas reinforced concrete,with20300

θpiles at 22mdeep.With the tower crane

erectedand sufficient foundations cast the

erectionof the façade retention commenced,

threemonths from taking initial possessionof

the site.

Deliveries of the façade retention steelwork

had tobe carriedout between5and6am. The

initial phaseof the façade retentionhad tobe

undertakendurationnight shifts, reducing

the interfacewith thegeneral public as the

first sections of the steelworkpenetrated the

pavement zone. Thesewere also restricted to

sixhourspernight andonly fournights of the

week.

Once the steel framehadpassed the

pavement zonewithprotectionafforded to

thepublic, the façade retention installation

continuedduringnormal day shifts, however

stillwith theoccasional night timeworking

where interfacewith thepublic existed (the

façade retention systemweighted inat 130

tonnes).

Toprogress thePortland stone façade and

stonedormerdismantlingworks above the

5th floor cornice as earlyaspossible in the

programme,Keltbraydesignedand installeda

cantilever scaffoldat 4th floor to support the

access scaffold required togainaccess to the

façades beingdismantled.

GROUNDWORKS

Another reasonwhyKeltbraywon the tender

was their ability toadvancemuchof the future

groundworksduring thedemolitionphaseof

theproject. Thegroundworks involved the

removal of the existingbasement structure

and foundations at the locationof themini

piles. Installationof 40450θpiles at 22mdeep

completewithvertical steel beams (known

as kingposts), a3m (9.8 ft) reduced level

excavationwith constructionof concretewall

panels between thekingposts and40m (131.2

ft) of 3mdeepunderpins.

Tomaintain thehighprofileof theproject,

TCE instructed thedesignand installation

of awrap to cover theoutsideof the façade

retention steel frame along theRegent Street

andNBS elevations, andanadditional

secondary steel framewasdesignedand

erected to the existingmain support steel to

ensure thewrapwas in straight line and level.

Due to thehigh cost of thewrap, façade

movementmonitoring couldnot be carried

out externally since thiswouldhave required

holes tobe cut in thewrap toview the targets.

Thebasement linemonitoringwasdone

prior to the installationof thewrapbut the

remainingmonitoring couldonlybe carried

out from inside theproject of theworking

floors inandaround thedemolitionworks.

Rotating targetswere installed to the reveals of

the existingwindows toallowview externally

for thebasement line and then internally

during theworks.

Once the façade retention steel framewas

installedand signedoff and thePortland stone

and thehigh level roof demolitionworkswere

completed themain structural demolition

commenced from the5th floor level down to

the existingbasement level.

■

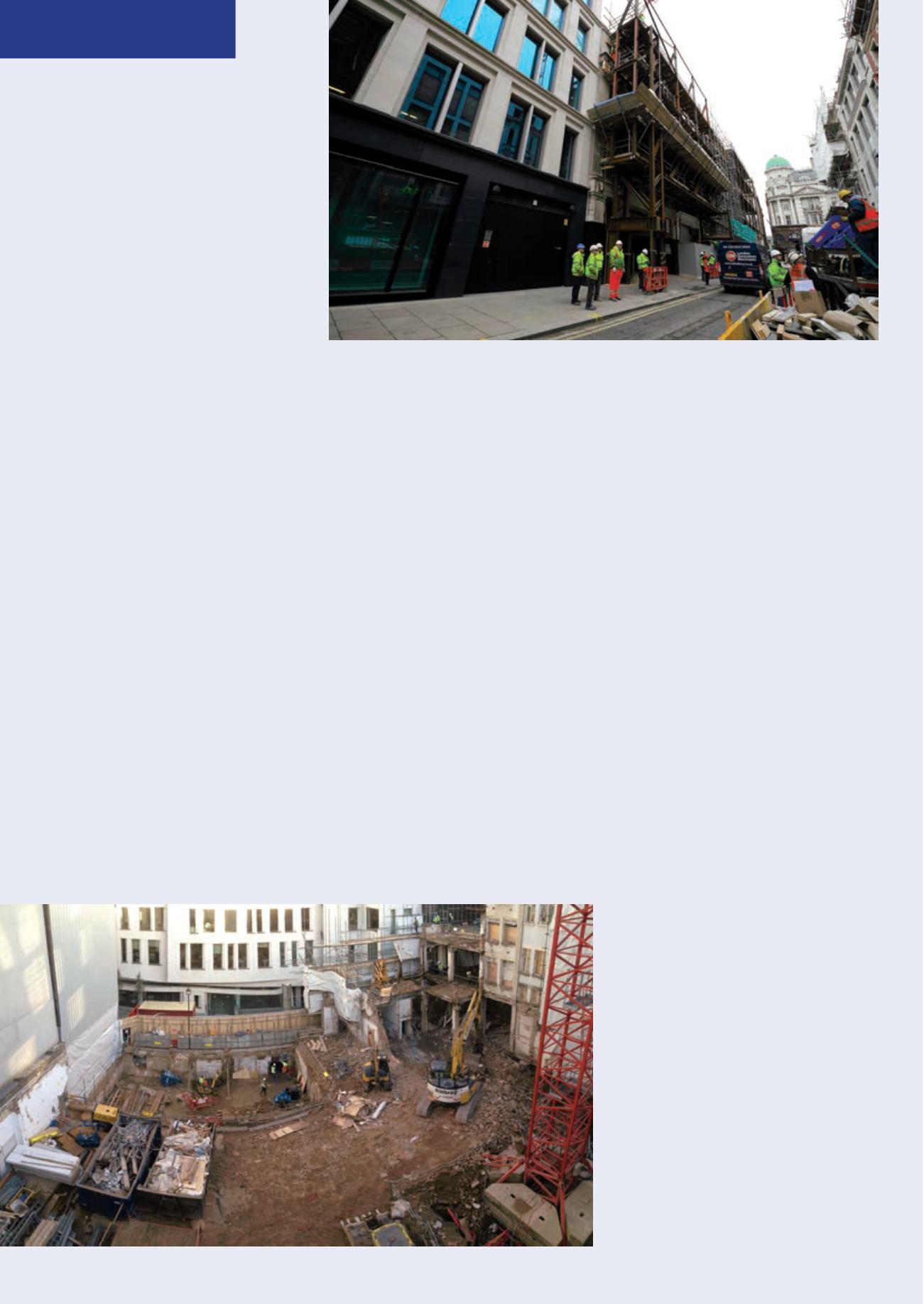

Site entrance situated in the retained

façade onNewBurlington Street and

neighbouringW4 Construction site

pit lane onNewBurlington Street

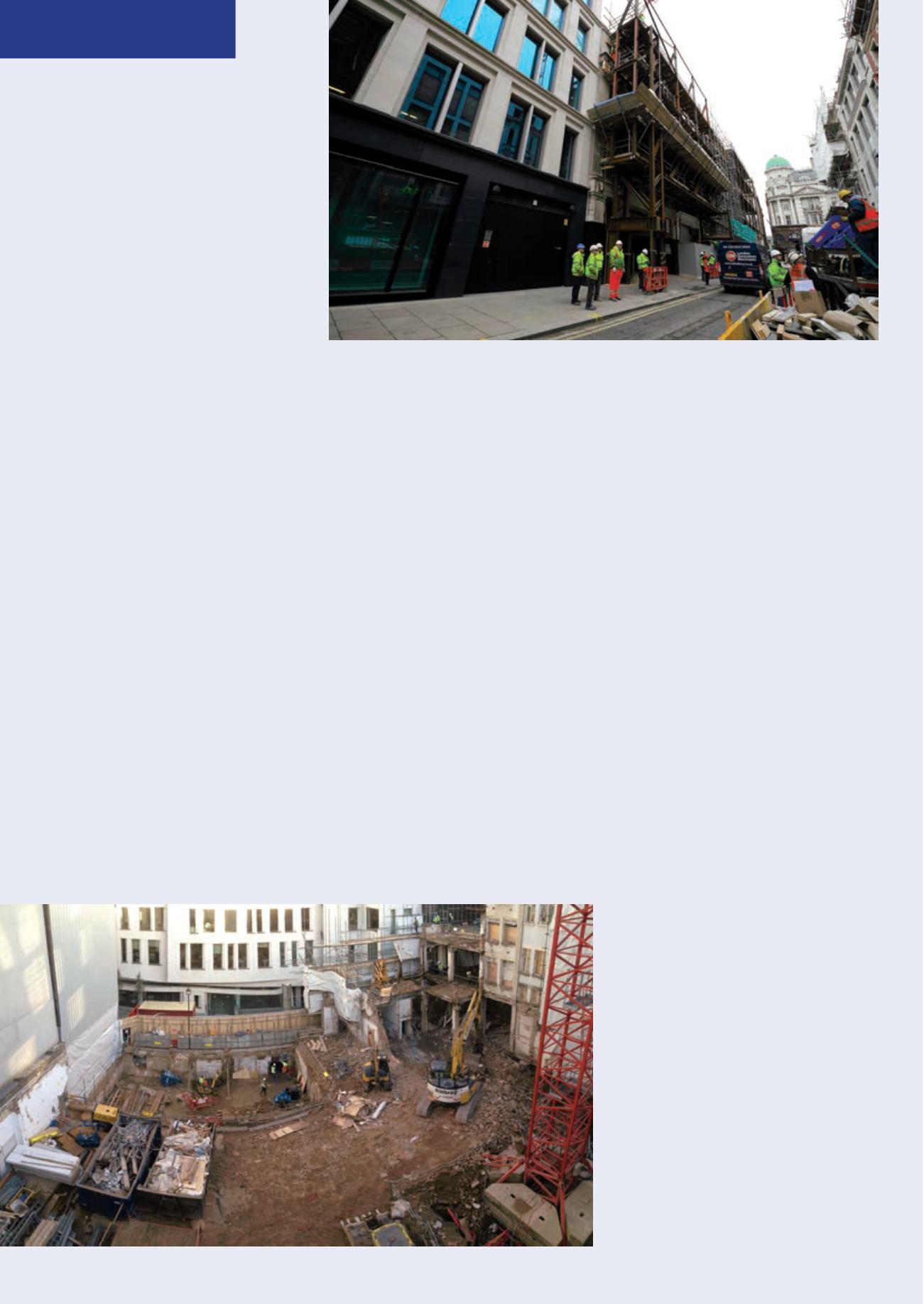

Structural demolition being carried out andwaste

segregation in progress