15

d

&

ri

NOVEMBER-DECEMBER 2014

andprocessed the scrapmaterials to export

size for shipment toAsia tobe recycled.

Liberty Industrial’s resourceful and

innovative approach towastemanagement

and environmental stewardship significantly

minimised the amount ofwastedisposed in

landfill. 108,000 tonnes (97%) of the site’s

111,000 tonnes ofwastewas recycledwith

only3,000 tonnes of allwaste going to landfill.

In addition to the 7,000 tonnes of plant and

equipment items salvaged and12,000 tonnes

of scrapmetal recycled, Liberty Industrial

found resourceful solutions todisposeof

25,000 tonnes of concrete andwasteproducts

from theHismelt process, including50,000

tonnes of slagwaste, 7,500 tonnes of dolomite

and5,000 tonnes of large irons skulls,

sourcingbuyers andprocessingmaterials

to their specifications and consulting

geotechnical engineers andblending fill

materials;

Liberty sourced a local buyer for the 25,000

tonnes of concretewhowas looking for a

supplyof roadbaseover a fourmonthperiod.

The concretewas pulverised to remove 1,500

tonnes of reinforcing so that crushing could

bedonequickly and efficiently. In addition,

50,000 tonneof slagwaste from theHIsmelt

processwas crushed into14mm roadbase

and stone, and sold for reuse. Abuyerwas

also sourced for the 5,000 tonnes of large iron

skulls that containedupwards of 70% iron

and thematerialwas processeddown to4 to

5 tonneblocks so that it couldbe loadedonto

abulk scrap ship and shipped toVietnam for

recycling.

In lieuof disposingof the 7,500 tonne

of dolomite offsite, Liberty consulted

geotechnical engineers about its suitability

as fillmaterial.Once a suitableblendof fill

materials hadbeendetermined, thedolomite

DEMOLITION AWARDS

was incorporated and reused across the site as

backfill.

Balancing the conflicting interests of key

stakeholderswho come to theprojectwith

different expectations and interestswas

critical to the success of theHismelt project.

With two clients to satisfy, Liberty Industrial

managed the keyobjectives of the twoon the

project;Molong’s keydriverwas the timely

executionof theprojectwhileRioTinto’s key

prioritywas compliancewith stringent safety

and environmental standards.

Liberty achieved ahigh level of client

satisfaction through value adding andhigh

standards of service anddelivered this project

in accordancewithRioTinto’sworld class

standards and compliance requirements

for themanagement of health, safety,

environment andqualityperformance.

Liberty Industrialwas able to realise

maximum value from anumber of reusable

plant, process equipment and scrapmaterials

anddeliver a cashpositiveproject outcome

forRioTinto through efficient demolition,

and innovative asset recovery and resources

recovery solutions. Theplant closureproject

delivered forRioTintowas cashpositiveby

approximately$3.5 (€2.8)million. In addition,

Liberty Industrial alsodeliveredoptimal

project outcomes forMolong. The ground-

breakingdismantling and salvage operation

was a complete success; deliveredwithin

budget, on schedule, without incident and in

accordancewith their exacting specifications.

The specialist expertise and experience

of Liberty Industrial’s personnel together

with state-of-the-art demolition simulation

technology ensured a safe and sustainable

outcome; Liberty Industrial successfully

completed115,000manhours ofworkon

theprojectwithout a single lost time injury,

recyclingover 108,000 tonnes ofmaterial.

■

TheExtremeLoading softwarewas used

to3D simulate the induced collapsemethods

to ensure that the companywas satisfiedwith

themodeof failure, pre-failure structural

stability and the effects ofwindon the

weakened structure.Modelling the structure

and simulating theproposeddemolition

methodology allowedLiberty to refine its

methodology anddemonstrate a successful,

safe and controlledoutcome to risk averse

clientRioTintowell in advanceof executing

the task. Through this simulationLiberty

was able to test its proposeddemolition

scenario involving initial weakening followed

bypullingusing cables and todetermine

thepulling force required to collapse the

structure. The applicationof this innovative

technologywas akey factor inmitigating

andmanaging thepotential risks associated

with the task, ensuring the structurewas

demolished in a safe and controlledmanner.

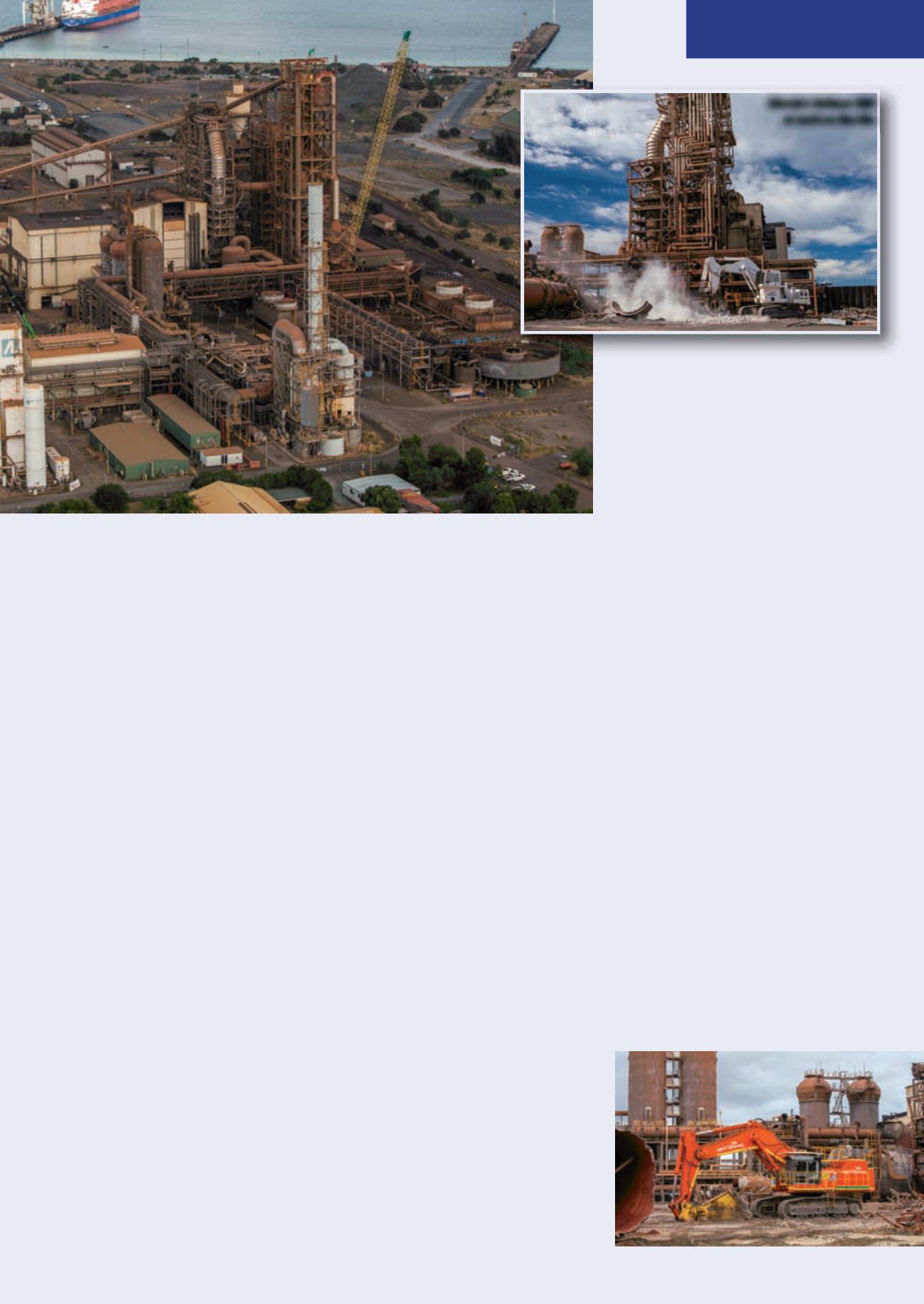

Once thehigher structureswere at

ground level thedemolitionof theplant and

infrastructurewas undertakenbyLiberty’s

heavyduty customised230 tonneLiebherr

994 (Australia’s largest demolition excavator).

Thismachinewas assistedby a 120 tonne

Hitachi, two46 tonne and five 36 tonneVolvo

excavators, two semi tippers, two telehandlers,

a 40 tonnedump truck, water truck, service

truck and various sizedboom lifts.

Various structures, including theoff gas

hood, smelt reduction vessel and the lock

hopper, were collapsedusing controlled cut

andpull demolition techniqueswhereby

engineeredpre-cutting and inertia is utilised

tobring taller structures toground level.

Working in combinationwith a smaller

fleet of excavators equippedwith shear

attachments, the 230 and120 tonne excavators

pulled the structures apart. The remaining

structureswere systematicallydemolished

and thematerials processed. Excavatorswith

various demolition attachments downsized

Liberty’s Liebherr 994

atwork on the site

AHitachi EX1200 atwork processingmetal scrap

ready for shipment and recycling