A newAward, theWorldDemolitionAward, wasmade for

the first time this year. This goes to the entry that the judges

considered to be the best overall entry of the year. The first

recipient was Liberty Industrial, and itswork also gained the

2014 Industrial DemolitionAward for this project

Pick of the

bunch

DEMOLITION AWARDS

14

NOVEMBER-DECEMBER2014

d

&

ri

of industrial plant and equipment,

including four bulk shipments of

over 18,000m

3

(635,500 ft

3

) and

280 shipping containers of plant

and equipmentwas salvaged and

shipped toShandongProvince in

China.Over 2,000bulkunitswere

methodicallydismantled, cleaned

to export standard,matchmarked,

labelled, recorded andpacked, with

each itemgiven clear instructions on

how tobe reassembled inChina.

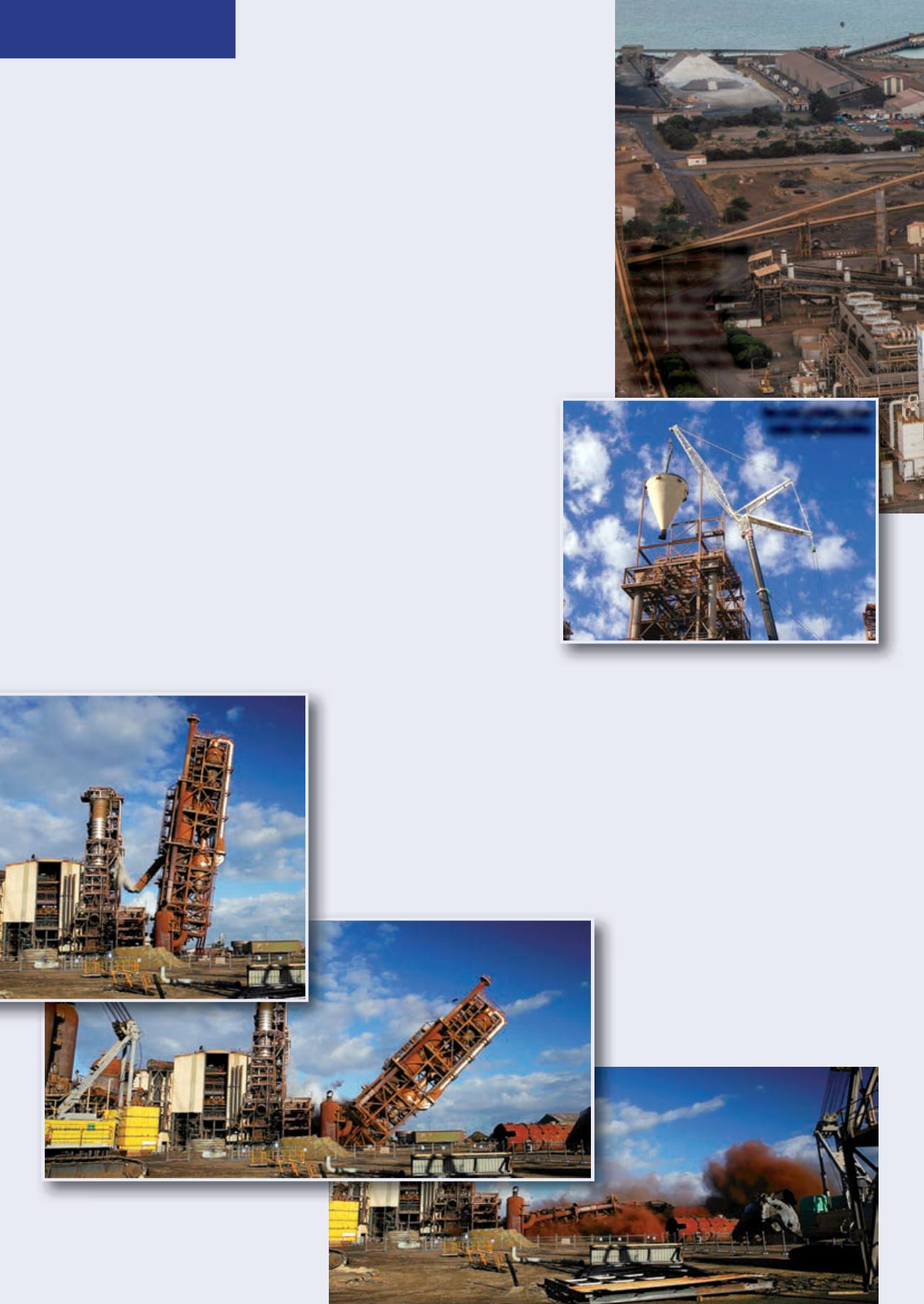

The salvaged items included

the 65m (214 ft) high, 1,200 tonne

coal drying andgrinding structure,

the flue gas desulphurisationplant,

hotmetal handling equipment, including an

80 tonne induction furnace, thehotmetal

desulphurisationplant, off gas scrubbing and

cooling infrastructure and a 25megawatt

power station. Carryingout lifts of up to108

tonne, thedismantlingprocess reliedheavily

on complex engineering lifts using large

crawler andmobile cranes.

Throughout theproject Liberty Industrial

managedmultiple crews acrossmultiple

workfrontswithin a small footprint.

Theprojectworkforcehit its peak in the

dismantlingphaseof theproject at 60

personnel including significant senior

management and a supervisory teamof two

projectmanagers, three safetymanagers,

five supervisors and three leadinghands,

supportedby a teamof fiveproject engineers.

Once thedismantlingphaseof the

project hadbeen successfully completed,

Liberty Industrial commenceddemolition

of themajor structures, utilising engineered

induced collapsemethods todemolish the

larger structures, including the 75m (246

ft) tall, 1,700 tonnepreheater structure. This

structure, due to risks associatedwith its

proximity to adjoiningoperating industrial

facilities, wasmodelledusing the company’s

proprietaryASI ExtremeLoading software.

Liberty Industrial implemented its

DemolitionRiskAssessmentWorkshop

(DRAW) systemon theproject. TheDRAW

system forms part of its thirdparty certified

AS4801:2001SafetyManagement System and

is the foundation for the company’s approach

tohazard and riskmanagement. The resulting

DRAW then feeds down to thedevelopment

of task specificRiskAssessments and Job

HazardAnalyses.

L

iberty Industrial carriedout the

deconstructionof RioTinto’sHigh

Intensity Smelting facility inKwinana,

WesternAustralia. Theproject involved

thedismantling and relocationof almost

half of theHismelt plant, whichwas sold to

Chinese companyMolong anddismantled

and shipped toChina for reconstruction. This

undertakingwas the first of its kindwith the

project involving the complexdismantling

of significant components of industrial plant

- never beforehas adismantlingproject of

this scale and complexitybeen attempted in

Australia.

Deconstructionworks commenced in

January2013with thedismantlingphase of

theproject. In total,more than7,000 tonnes

The 75m tall, 1,700 tonne

preheater structure falls

following a simulation of

the collapsemethod

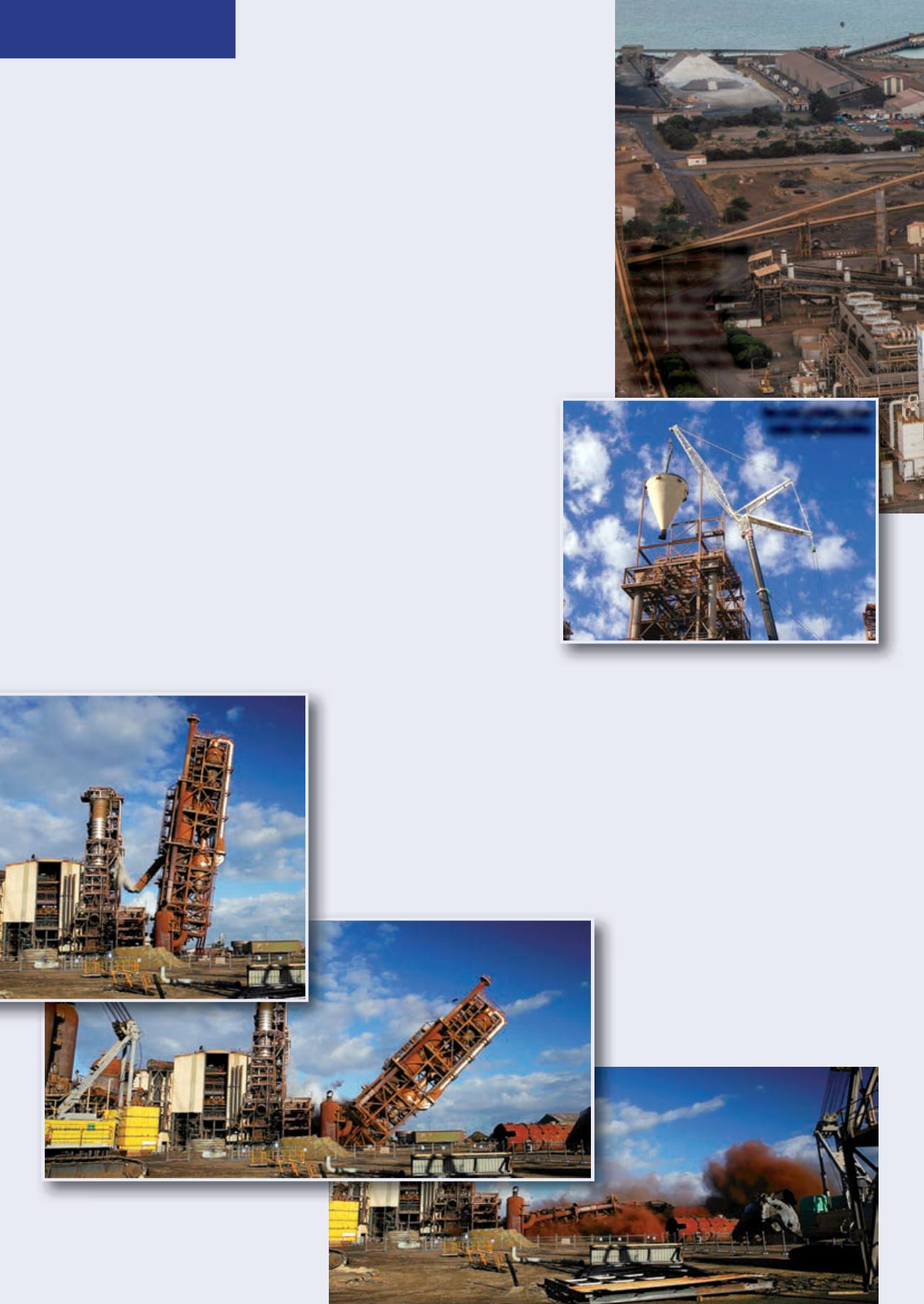

Rio Tinto’s High Intensity

Smelting facility in

Kwinana,Western

Australia. Almost half

of the plantwas sold

to Chinese company

Molong and dismantled

and shipped to China for

reconstruction

The coal grinding plant

under deconstruction