33

AUGUST 2013

ACT

INSPECTIONS

INDUSTRY FOCUS

Up and

running

Peter Juhren

explains that

resurrecting a tower crane

that has been mothballed

requires a strategic

inspection process and

due diligence.

in compliance with the manufacturer’s

instructions, as well as state and federal

regulations. In many cases this can

amount to 50 percent or more of the

anticipated rental income for the first job

after refurbishing.

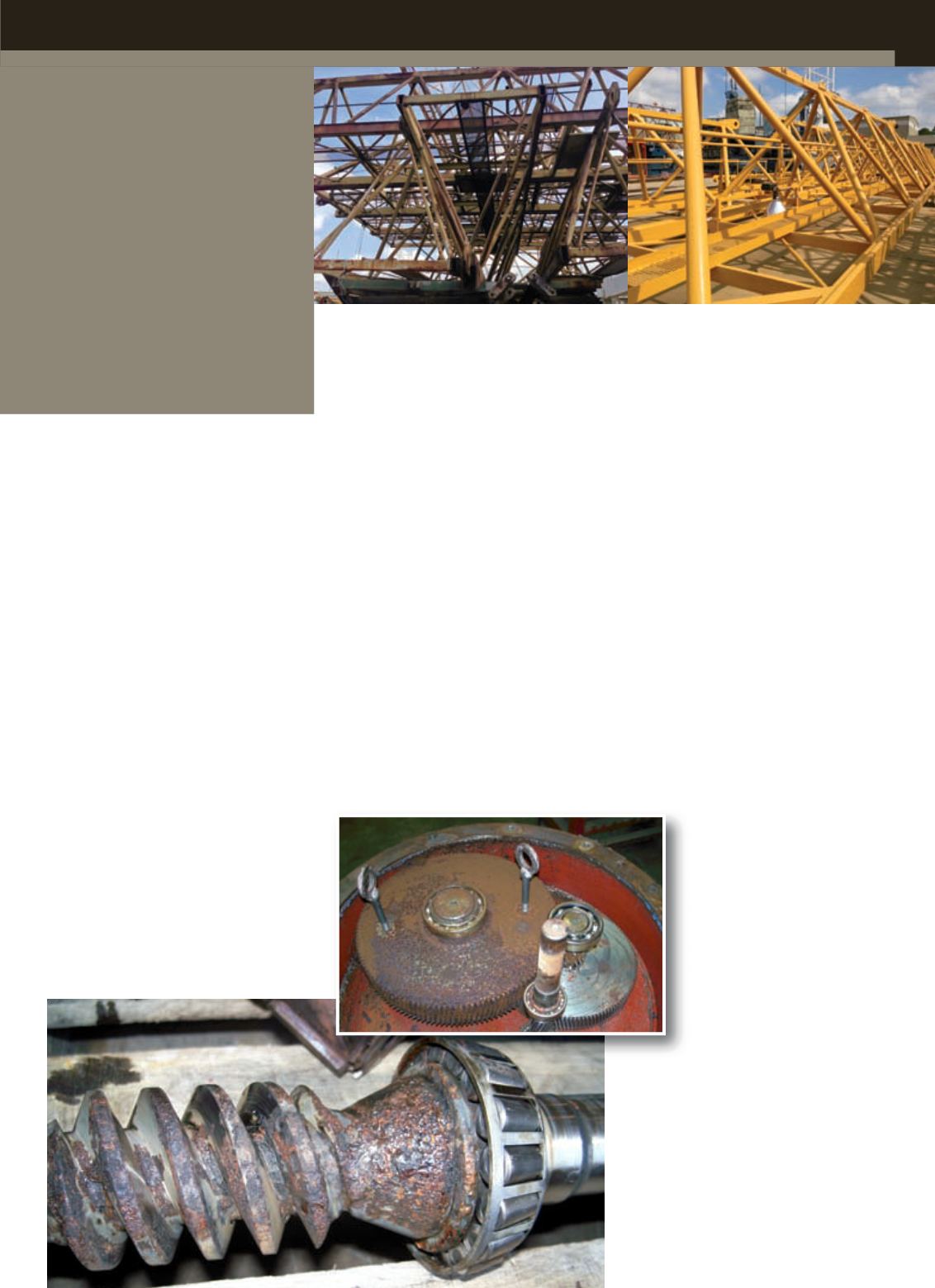

It’s not a matter of simply changing some

oils and making sure the crane runs. To

properly complete a thorough refurbishing

requires a tear-down of all drives,

inspection of the entire steel structure

and replacement of many key electrical

components, such as motor refurbishing.

Complete assessment

First course of action is to assess the crane

completely. Moving the crane to an open

staging and inspection area makes the task

easier and more complete.

Having a dedicated and written Quality

Control/Quality Assurance program is

important to ensure the evaluation meets

the requirements your company has

dictated to achieve the level of quality

expected. For the first evaluation, assess

the complete steel structure, looking for

previous damage or damage that may have

occurred during storage and

handling. If the structure has

severe corrosion, NDT testing of

suspected areas may be required.

An engineer with expertise in

this area should be consulted.

It is strongly suggested that

all structural hardware is

NDT tested. At Morrow, we

inspect and NDT test all of our

structural bolts on a rotating

cycle.

Test the electrical motors. If

the crane was stored outside, at

a minimum the motors should be dipped

and baked to ensure the insulation has

not deteriorated causing premature failure

once the crane has been put back into

service. Key here is to use a quality motor

shop that understands how your motors

are wound.

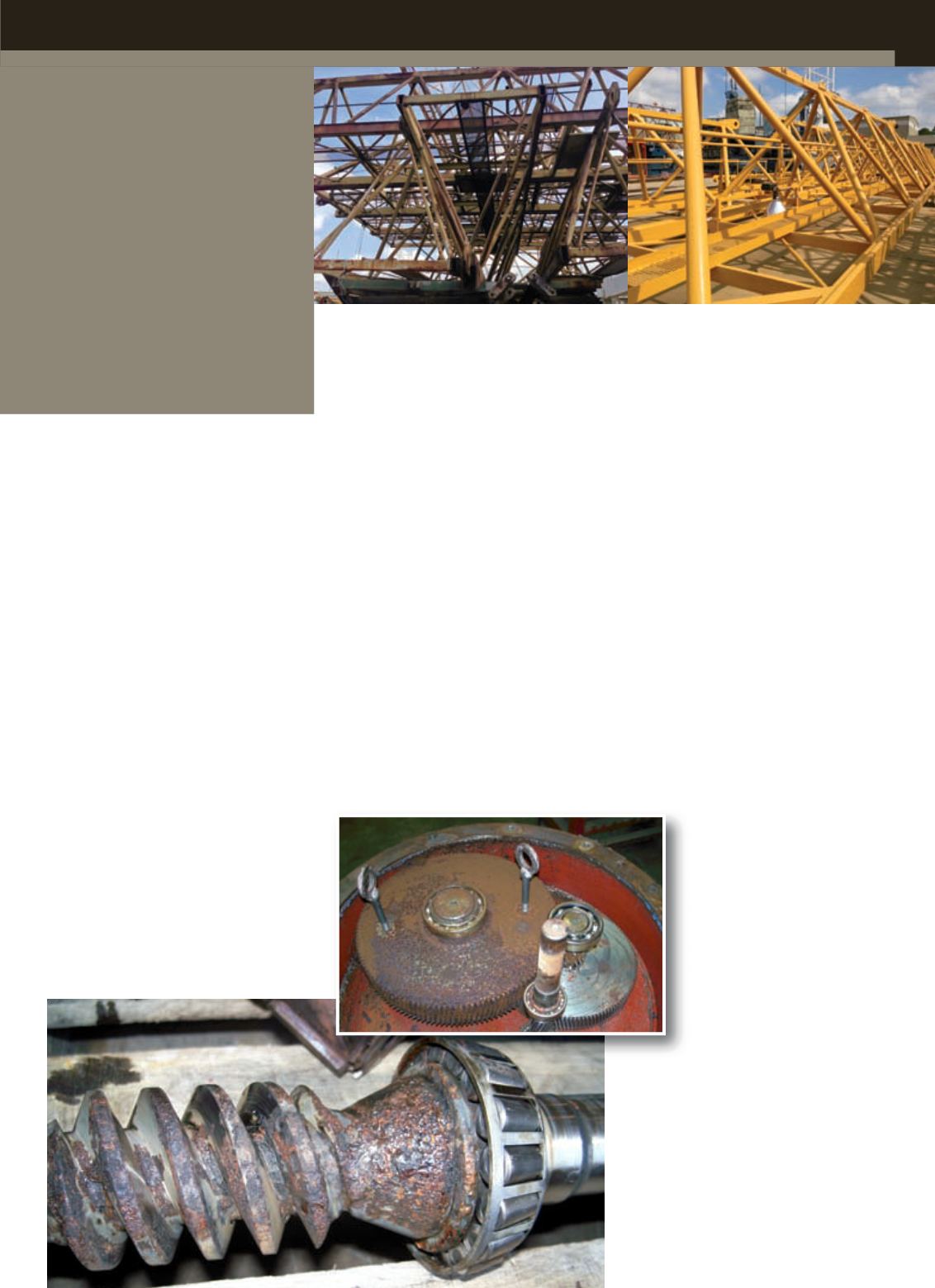

Inspection, repairs and a new paint

job can give a mothballed tower

crane many hours of safe service.

T

he tower crane industry is finally

starting to gain traction after

four years of the worst down

market in history. Fleet utilization is

steadily climbing after dropping below 25

percent, and backlogs for most companies

continue to grow.

Tower crane sales are still very soft

as the market continues to absorb the

excess inventories still present with most

crane owners. The failures of some larger

companies also added to excess inventory

issues between 2008 and 2011. Rental rates

for tower cranes have slowly risen, but still

remain depressed. The outlook for the

second half of 2013 into 2014 is predicted

to see a continual increase in monthly

revenue.

As the utilization of tower cranes

continues to grow, rental fleet and

individual owners face another pressing

issue – how to restore their fleets after so

many cranes sat idled and stored.

Resurrecting a tower crane that has

been mothballed requires large sums of

money, time and due diligence to restore

the crane to its original condition and stay

Don’t simply fix things. Develop a step-by-

step inspection plan to ensure compliance.

Done properly, a refurbished crane can

perform as good as a new one.