AUGUST 2013

ACT

37

SPECIALIZED LIFTING

PRODUCT FOCUS

at the same time, until it could be lowered

5 feet, 6 inches below grade. Once it was

below grade we were able to then skate the

unit, with our steerable rollers, into a live

energy center at the university.”

Martin says the rigging plan required

strategies for every scenario.

“We had to really think about how we

were going to safely finish the project

under the time constraints that we were

given,” he says. “We had to think about the

feasibility of many options. Ultimately our

team decided the gantry, skates and GMK

7550 would be the right equipment. This

was truly a job that involved many of our

companies’ resources and teams.”

Bridging the gap

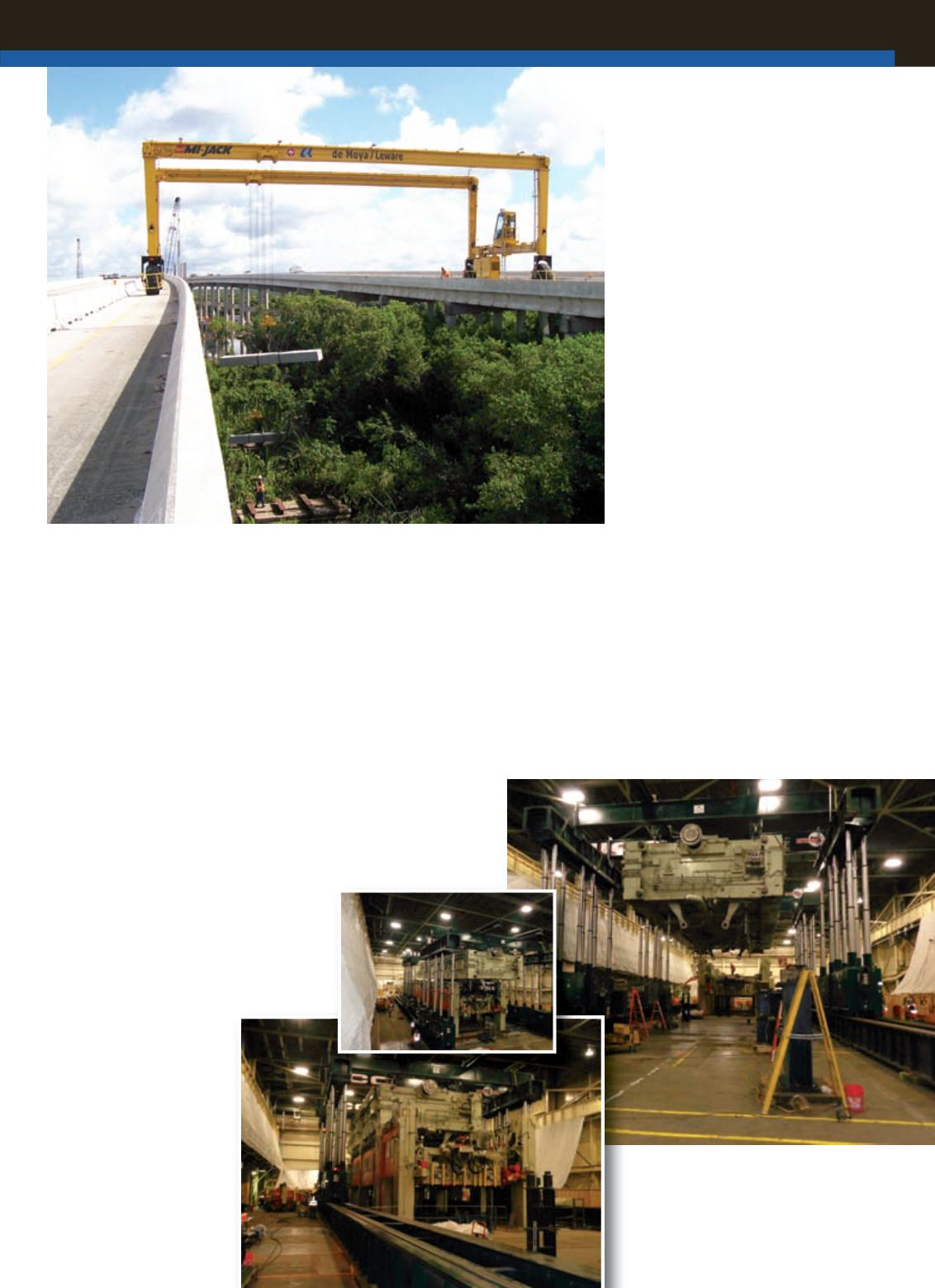

An AccuSteer Differential GPS navigation

system by Mi-Jack Products is a key

component for a project in Central Florida

that involves the addition of two lanes

to the Caloosahatchee River Bridge. The

bridges are high-level, fixed structures

over a major navigable waterway and

require heavy construction

activities in an

environmentally sensitive

area.

The construction

companies chose to use

a pair of MJ70 Travelift

cranes to implement a

top-down construction

method. The cranes are

handling piling, bridge

beams, decking and

reinforcement materials.

The MJ70 Travelift cranes were built to

specifications to have an 83-foot, 6-inch

inside clear width, 25-foot, 5-inch hook

height, and a 40-foot wheelbase. The

construction companies also chose to use

the Mi-Jack AccuSteer Differential GPS

navigation system based on the precision

required to steer the machines on such

tight aisle ways as well as the large span

between the tires.

AccuSteer is a sophisticated navigation

system based on leading differential GPS

technology employing

precision GPS

navigation, according

to Mike Lanigan, Jr.,

Mi-Jack Sales manager.

“The system is crucial

to this job as it allows the operator

to concentrate on the loads they are

moving,” he says. “This is made possible

because the AccuSteer Differential GPS

navigation system generates information

on the cranes’ position within accuracies

of 2 centimeters by employing two sets

of dual-frequency receivers and antennas

fixed to each of the cranes and one set

located at the base station. Solar-powered

base stations were placed at the peak of

the bridge outside the lanes of traffic.”

The clear line of sight allows the

Navigation Processor to accurately

generate steering correction data for the

crane’s electronic control system, which is

then translated into crane movements.

“That process allows the cranes to

travel along a GPS-generated pathway

to within plus or minus 2 inches of the

center line of the tire,” Lanigan explains.

“Without this system the job would not

be completed as efficiently as it could be.”

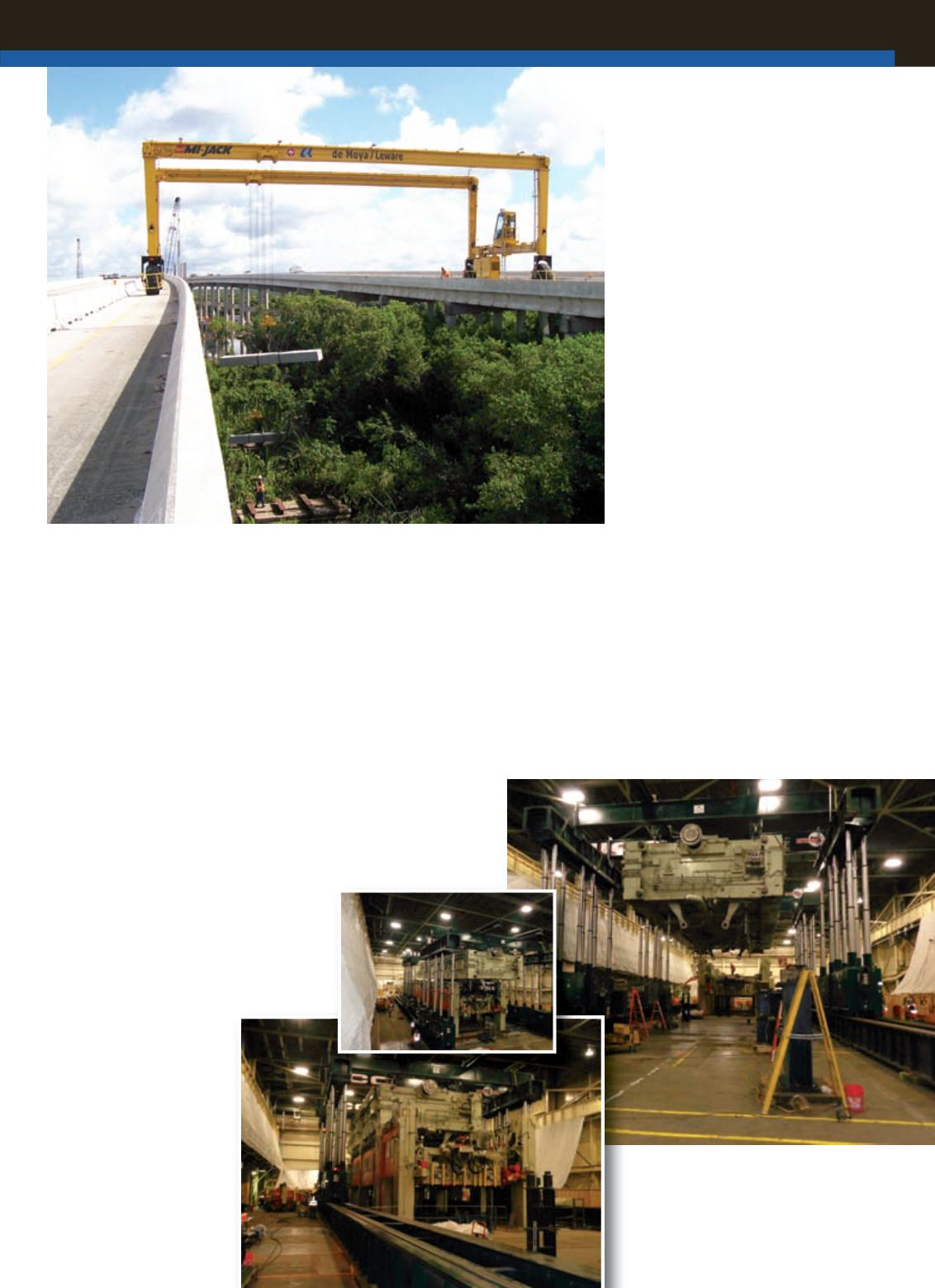

Transfer press conundrum

General Motors awarded International

Industrial Contracting Corporation (IICC)

a project that involved the installation of

an IHI 6,500-ton capacity transfer press

system for GM’s Fairfax assembly plant in

Kansas City, MO.

The new press was a critical addition

to the automaker’s ability to turn out

new models of Chevy Malibu and Buick

LaCrosse, according to IICC’s Randall

Goddard.

A pair of Mi-Jack MJ70 Travelift

cranes are used to implement

a top-down construction

method to add two lanes to the

Caloosahatchee River Bridge.

The cranes are handling piling,

bridge beams, decking and

reinforcement materials.

International Industrial Contracting

Corporation installed an IHI 6,500-ton

capacity transfer press system for GM’s

Fairfax assembly plant in Kansas City, MO.