36

PRODUCT FOCUS

SPECIALIZED LIFTING

Crane Service Inc. developed a rigging

plan that would involve the use of its

Grove GMK 7550 all-terrain crane,

Amital USA - AL12G steerable rollers

and a Model 22A 220-ton, 2-point lift

system rented from Rigging Gear Sales.

With such a short window of time,

rapid dispatch of the equipment to the

jobsite was critical.

“We had to check on the availability

of the gantries and delivery of such

from Dixon, IL,” Martin says. “We had

to mobilize our Grove GMK 7550 a

week after being awarded the job. The

Grove GMK 7550 was already on a job

in Colorado. We had a zero hour, if you

will, of when we needed the GMK 7550

to finish. It did come close, but we were

able to finish in Colorado and make it

back to New Mexico on time. We are

thankful that Rigging Gear Sales was able

to help us on short notice.”

Martin says the ingenuity of the rigging

plan was the key to the success of the

project.

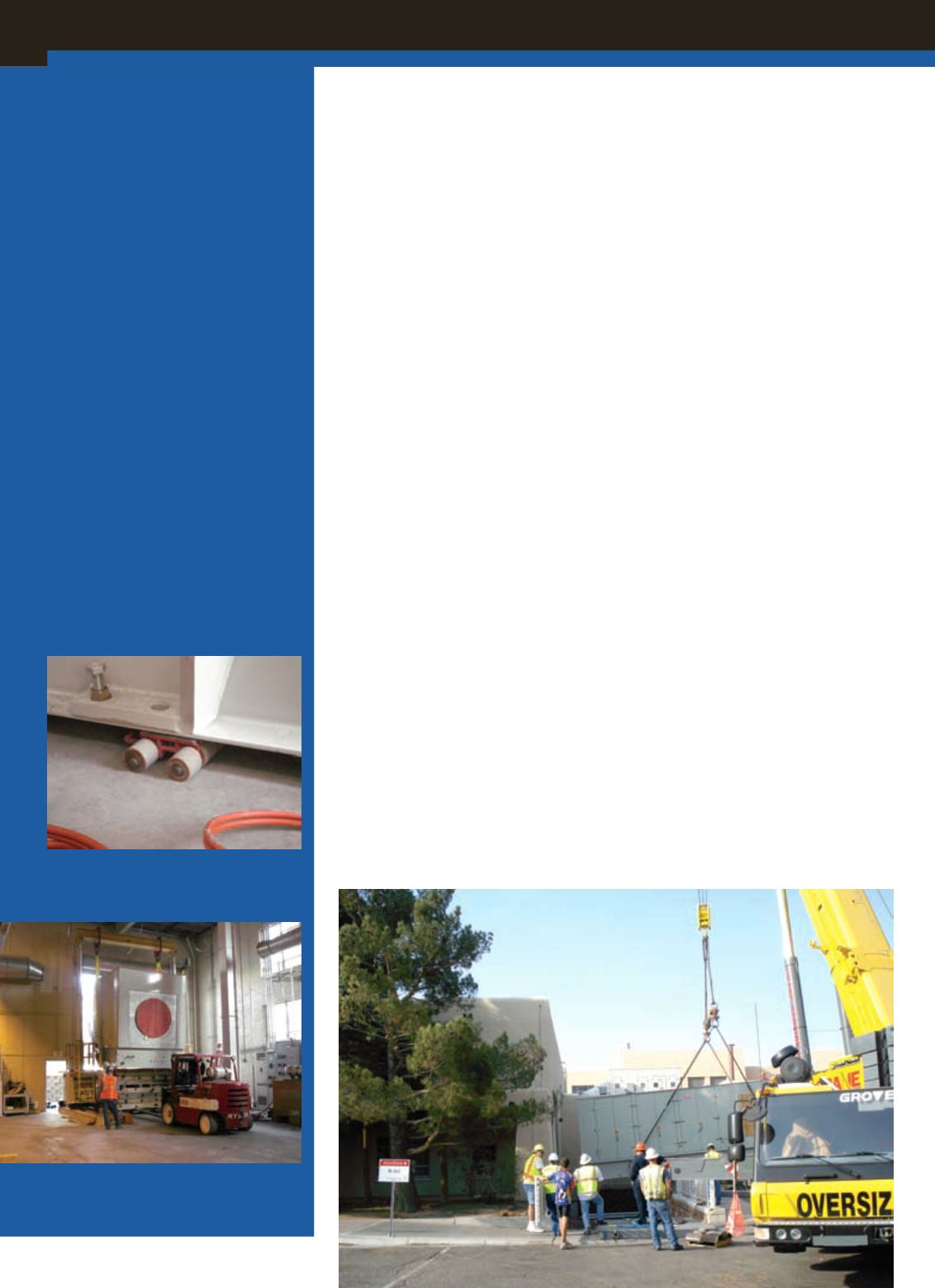

“Site wise, the project area was very tight,

with only 10 inches between the gantry,

natural gas turbine and a roll-up door,” he

says. “The gantry could not go through

the doorway with the turbine. Instead,

the natural gas turbine had to be set in

part way with the Grove GMK 7550. We

had to hoist with GMK 7550 and gantry

ACT

AUGUST 2013

Ingenuity is the name

of the game when

it comes to rigging

projects that require

specialized lifting

equipment.

Super

specialized

Crane Service Inc.

developed a rigging

plan that would

involve the use of

its Grove GMK 7550

all-terrain crane,

Amital USA - AL12G

steerable rollers

and a Model 22A

220-ton, 2-point lift

system rented from

Rigging Gear Sales.

The turbine measured 35-feet, 7-inches

long, 10-feet, 2-inches wide and weighed

123,500 pounds.

Crane Service crews had a small working

area with only 10 inches between the

gantry, the turbine and a roll-up door.

S

imply put, things that need

lifting are getting bigger,

heavier and more awkward.

For this reason, rigging and lifting

jobs are more complex than ever and

require solutions that involve all types of

specialized lifting equipment.

With the power grid in the United

States needing expansion, upgrading

and replacement, among the most

challenging rigging jobs are those that

involve transformers, turbines and other

power plant components and vessels.

Manufacturing facilities are also retooling

and updating their plants, which means

putting heavy equipment in tight spaces.

Turbine enigma

Crane Service Inc. was award an

intriguing project at the University of New

Mexico – Albuquerque. The job involved

installing a natural gas turbine, formally

known as Taurus 70S Onshore Power

Generation Turbomachinery. The turbine

measured 35-feet, 7-inches long, 10-feet,

2- inches wide and weighed 123,500

pounds.

“Scheduling was one of the first

challenges we faced,” says Chris Martin,

marketing coordinator for Crane Service

Inc. “We were awarded the job on a

Thursday morning, a week before the job

was set to take place.”