42

SITE REPORT

LIFTING

ACT

reports on the

construction of the

world’s first precast

network arch bridge and

the rigging innovation

used by Burkhalter

Rigging on the jobsite.

New bridge for

for the city of Fort Worth, this precast

network arch bridge is a safe, sound and

high-quality structure that will benefit

both motorists and businesses.”

The new $26 million West 7th Street

Bridge, which replaces its 100-year-old

predecessor, is a unique and beautiful

design that offers much more pedestrian

access, Wilson says. The new bridge

features a series of sculpted network

arches and modern architecture.

TxDOT has a history of building

durable, high-strength, precast concrete

bridges quickly and at costs that

consistently rank among the least in

the nation, according to Wilson. The

innovative design of the Fort Worth

bridge met the challenges of quick

construction, aesthetic beauty and

improved mobility and safety while also

providing a large hydraulic opening to

mitigate flood conditions, the agency says.

Precast technology

“The idea was to turn to our successes in

precast technology and mass production

– only, we knew we wanted something

more attractive for the West 7th Street

Bridge,” says TxDOT Structural Engineer

Dean Van Landuyt. “Aesthetics were

paramount.”

The contractor, Sundt Construction

Inc. of San Antonio, began work over

T

he world’s first precast network

arch bridge, featuring 12 arches,

is changing the landscape of

downtown Fort Worth, TX. The West

7th Street Bridge is the first-of-its-kind

and will serve as a gateway to the city’s

cultural district, where buildings designed

by luminaries such as Louis Khan, Tado

Ando and Renzo Piano line the landscape.

“The West 7th Street Bridge design

and construction techniques are further

examples of Texas leading the way in

innovation,” says Texas Department

of Transportation Executive Director

Phil Wilson. “In addition to being an

architectural and engineering landmark

The new West 7th Street Bridge in Fort

Worth is a wider, safer alternative to its

100-year-old predecessor. Its design is

highlighted by the 12 lit arches that rise

about 20 feet above the roadway.

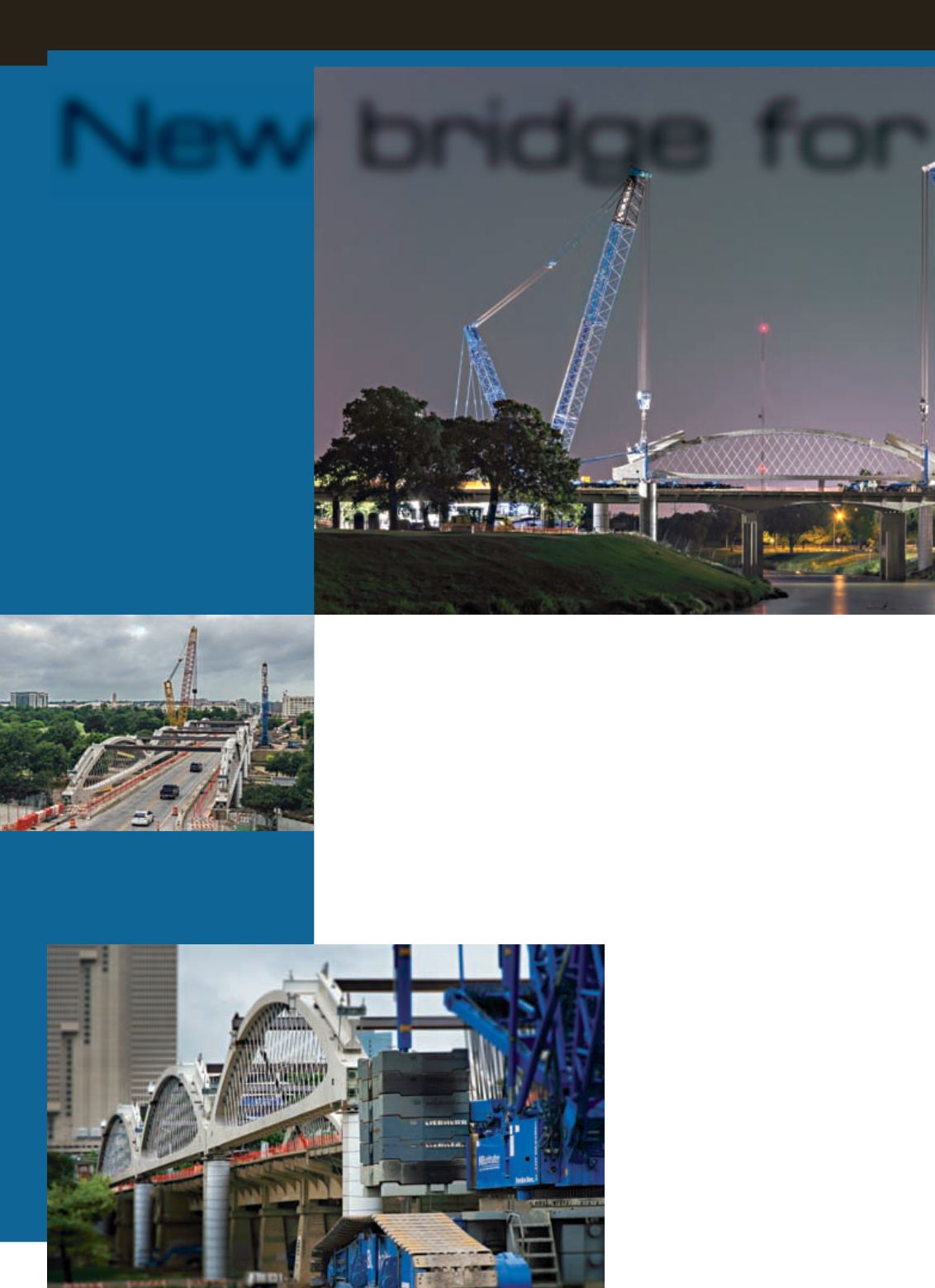

Burkhalter Rigging transported the arches

on SPMTs to the jobsite. Two Liebherr LR

1400s rigged with superlift attachments

were used to lift and set the arches on

columns.

ACT

AUGUST 2013