23

AUGUST 2013

ACT

RIGGING REVIEW

failure analysis, among other things, once

an accident has occurred.

Bristow recalls one particular case

involving a 1988 Krupp KMK5100. While

working on a water well installation

project in northern Mississippi, the

crane was being utilized to assist in the

extraction of a well casing. While in the

process of applying force to the casing, the

crane’s upper structure suddenly failed

and separated at the rear, directly behind

the rotation bearing and right in front of

the counterweights.

The break was so clean and so swift

that it caused a split between the upper

engine and the pump drive gearbox. The

boom fell and landed on a $350,000 drill

rig that was deemed a total loss by the

insurance company. The subject crane

was also deemed a total loss at $195,000,

with additional clean up and recovery

costs totaling some $40,000. The resulting

investigation revealed that a sticker on the

upper cab indicated that the crane had

been inspected and was actually certified

30 days prior to the accident.

Recalling the incident, Bristow notes his

theory. “Obviously one of two scenarios

took place,” he says. “Either an inspection

was never performed, and the sticker was

provided for a fee, or the inspector failed

to recognize a preexisting fracture that

measured 12.5 inches vertical on the right

side, 30 inches horizontal across the rear,

and 12 inches vertical on the left. You be

the judge.”

Regardless of what caused the fracture

to go unnoticed, the outcome remained

the same – equipment and property

damage totaling $585,000. And though

this particular case was fortunate in the

fact that there were no injuries, not all

accidents have the same results.

Crane inspectors are in a unique position

to look at the crane through a lens that

neither the crane operator, lift director,

general contractor, nor anyone else for

that matter, is practiced enough to see

through. They typically have time on their

side and can methodically go through a

crane’s mechanical, structural and boom

components with a great deal of diligence.

Routine inspections

According to Ray Feidt, CCAA president

and inspection/training manager for

Stephenson Equipment, routine and

regular crane inspection is extremely

important.

“The reason for routinely inspecting

a crane is to have a consistent review of

the condition of the crane and its specific

components,” Feidt says. “If a component

is beginning to show wear, then that

component must be carefully analyzed

during every inspection. An immediate

decision must be made as to whether the

component will be repaired, replaced or

continue to be monitored.”

Most companies in the construction

industry find common ground when it

comes to issues of safety. The heartache –

both financial and personal – a company

goes through when a serious incident

occurs on a jobsite affects almost every

company in the same way. Accidents have

a profound impact on everything from

employee morale to operating margin.

Because of this, safety as a category is

ever evolving. New technology, better

procedures and innovations in science all

play a pivotal role in safely moving the

industry forward. Each of the individuals

on a jobsite – regardless of his or her

position or role – has a duty to act safely.

Whether we’re advocating for more

adequately trained operators, riggers,

signalpersons or inspectors, when we

break it down fundamentally, we’re

ultimately arguing for a better industry.

Having higher standards for crane

inspectors to aspire to is just another

piece in the ever-evolving puzzle of crane

and rigging operations.

■

Inspection items:

Among the items that must be inspected

are: the crane structure, sheaves and

drums, pins and bearings, brakes, safety

devices, engine, tires, hydraulic hoses,

electrical components, pumps, valves

and wire ropes. See the OSHA regulation

for a full list of items that must be

inspected.

Three questions to ask

your crane inspector:

■

How much experience do you have

with this particular crane model?

■

What type of experience does you

have with this particular crane?

(As an operator, technician, etc.)

■

What type of insurance does your

company carry?

(General liability, professional liability,

etc.)

Six times your crane

should be inspected:

WHEN IT IS MODIFIED

Anytime a crane is modified, a qualified

person must inspect the modification.

WHEN IT IS REPAIRED OR ADJUSTED

Anytime a crane has had a repair to a

component that relates to safe operation,

it must be inspected by a qualified person

prior to initial use.

AFTER IT HAS BEEN ASSEMBLED

After assembly is completed, the crane

must be inspected by a qualified person.

Tower cranes must also have a pre-

assembly inspection

DURING A SHIFT

OSHA no longer requires a daily

inspection; instead, shift inspections

must be performed by a competent

person. Documentation is not required

for this inspection.

MONTHLY

The monthly inspection is simply a

documented shift inspection done by

a competent person. The employer is

responsible for maintaining the last three

monthly inspections, and they must be

made available to an inspector.

ANNUALLY (COMPREHENSIVE)

This inspection must be performed

by a qualified person and must be

documented. Disassembly is required, as

necessary, to complete the inspection.

In addition, a functional test must be

performed. Any deficiencies must be

assessed to determine if they represent

safety concerns. If so, the crane must

be taken out of service until repairs are

made.

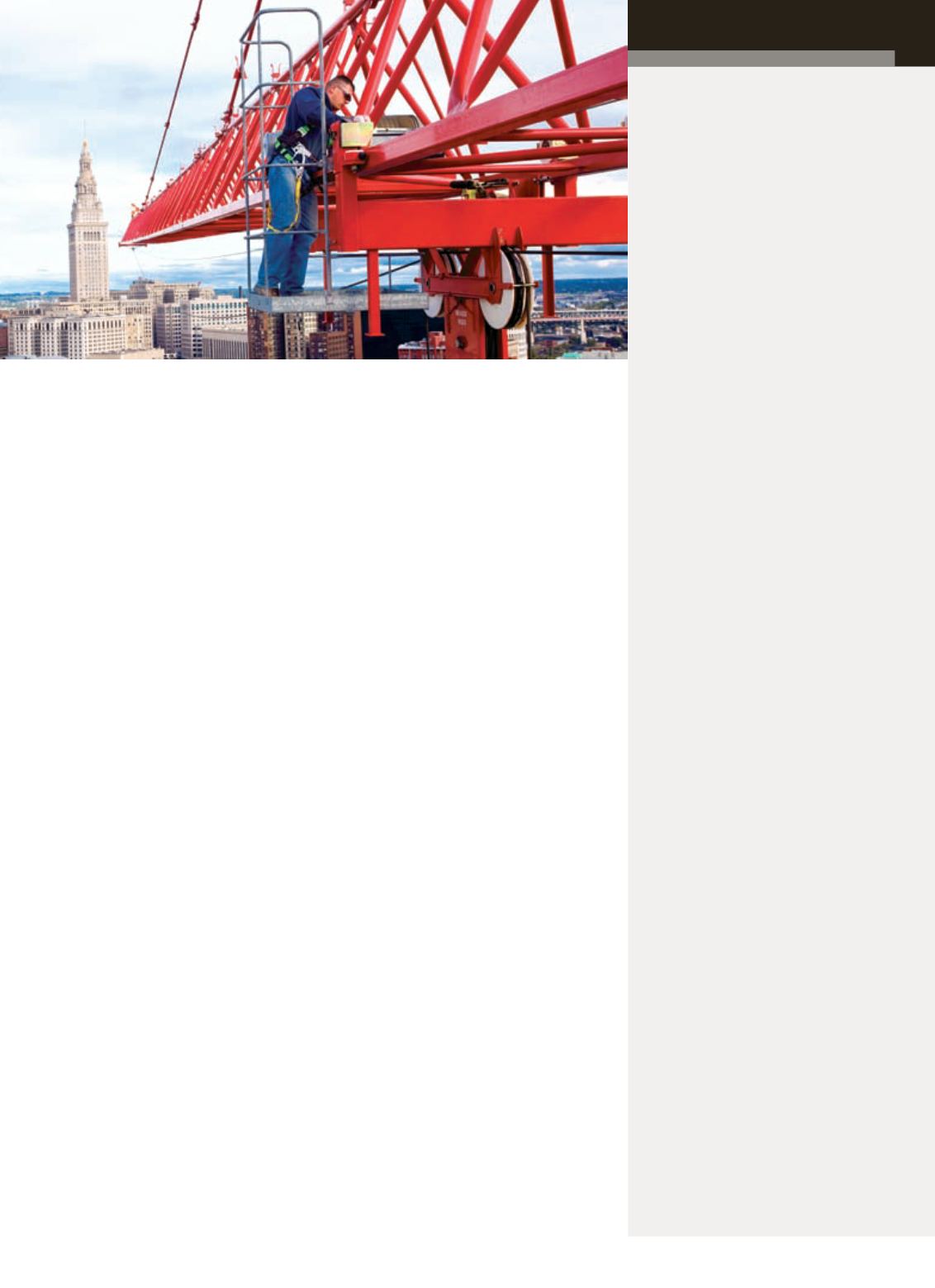

PHOTO COURTESY OF ALL

ERECTION & CRANE RENTAL.