31

Ekim

2013

international

construction

Türkiye

Ekİpman dosyası

Mikser teknolojilerinde yenilikler

Yeni kulelerde, GKA asfalt ilavesi iki

şekilde yapılabilmekte: bir geri kazanım

çemberi aracılığıyla ve bir asansör

tarafından doğrudan mikserin içinde. Bu

iki sistem birlikte kullanıldığında, %50’ye

varan oranda GKA kullanımı olanaklı

hale geliyor. Tesise GKA için ilave bir

paralel kurutma tamburu eklendiğinde ise

daha da yüksek oranlara ulaşmak mümkün.

eTower serisi, aynı zamanda ılık

asfalt alanında son dönemde ortaya çıkan

gelişmelerde de faydalanabilecek şekilde

tasarlanmış. Ilık asfalt karışımları, klasik

sıcak karışımlardaki gibi 140 ile 180°C arası

sıcaklıklar yerine, 90 ile 150°C arasında

üretiliyor.

Kaliteli bir ılık asfalt karışımının elde

edilebilmesi için, köpük bitüm gibi katkı

maddelerine ihtiyaç duyulmakta ve eTower

2500 modelinde de Marini’ye ait AQUABlack

köpük bitüm üretim sistemi dikkat çekiyor.

Sistem sayesinde, asfalt sıcaklığının 30°C’yi

aşan değerlerde düşürülebildiği ileri sürülmekte.

Ilık asfalt üretimi, enerji tüketiminin ve

emisyonların azalması gibi son derece açık

W

hatever the output needs,

manufacturers of mixing plants are

focussed on improving efficiency,

from consumption to more options for mixing

temperature and recipes, new control systems

and other environmental considerations such as

noise and fumes.

For instance, recycling old asphalt – also

known as reclaimed asphalt paving (RAP) – is

an absolute must in the industry, according to

Ammann.

In fact, Ammann claims to be the only

manufacturer that can offer plant technology to

produce new asphalt from 100% RAP and uses

a variety of technologies, depending on how

much RAP is added to the mix. It recommends

adding cold RAP directly to the mix for smaller

quantities of up to 30%, but provides a range of

specially designed drums for higher RAP rates

up to 100%. The RAH 100 drum, for instance,

can handle up to 100% RAP.

Ammann has also introduced a new asphalt

mixing plant, the Universal HRT, that is designed

to cope with up to 60% RAP. The plant features

a fully integrated parallel drum directly above

the mixer for optimal material flow, and has an

output capacity of 320 to 500 tonnes/hour.

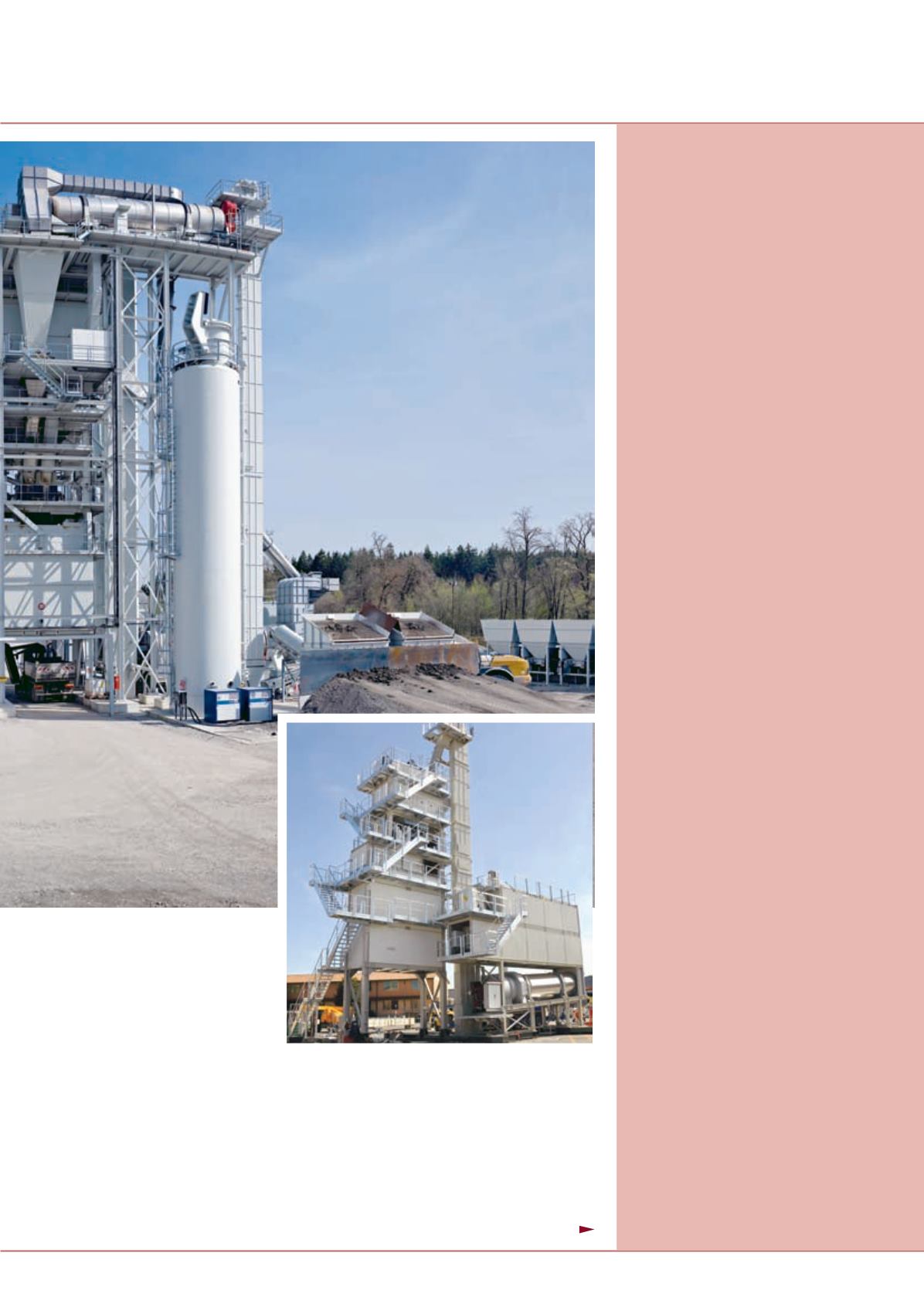

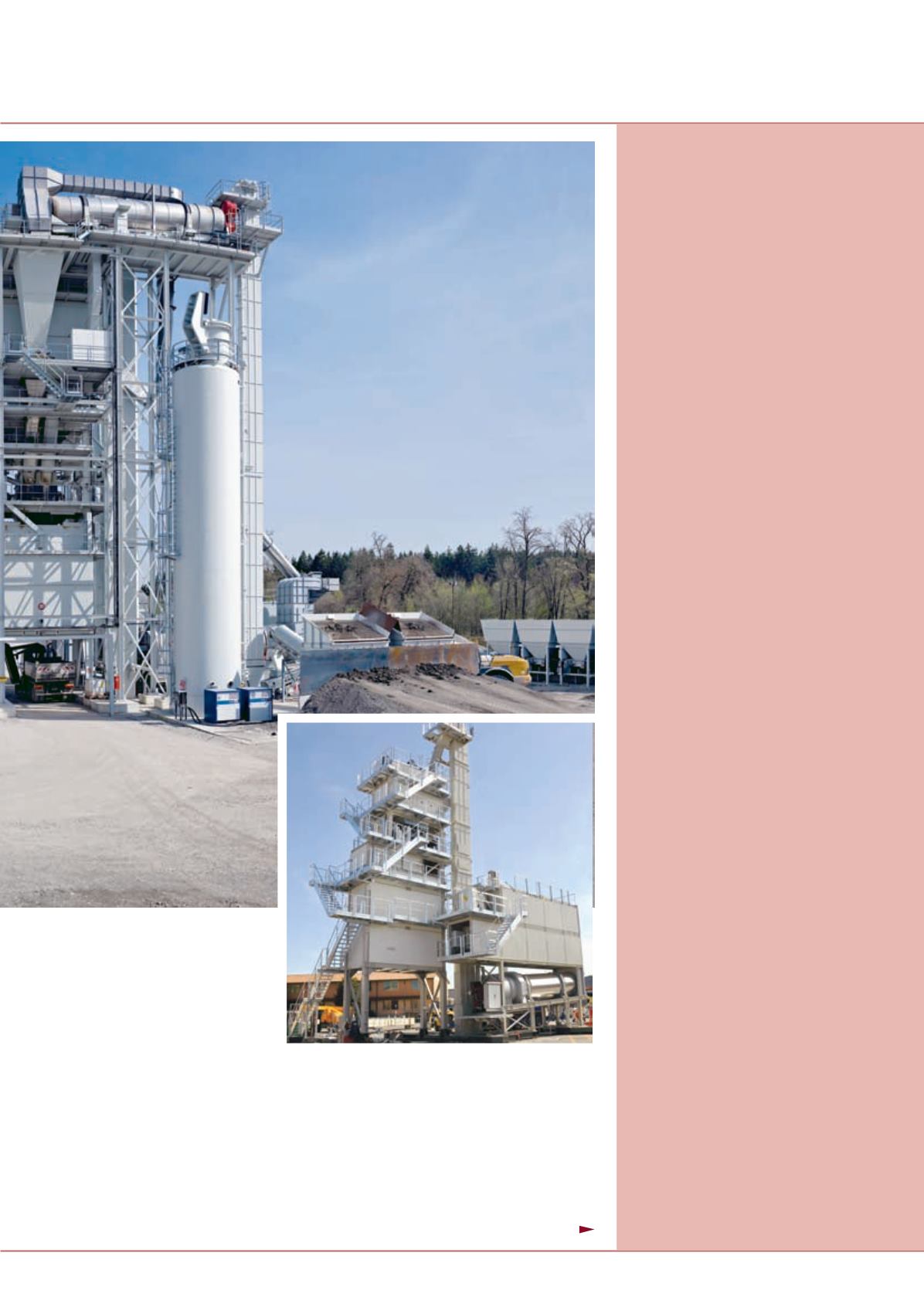

Fayat-owned mixing plant manufacturer Marini

is also developing new mixing towers focussed

on coping with higher quantities of RAP.

The company has introduced the new eTower

family of asphalt plants, which currently

consists of two models – the eTower 2000 (150

tonnes per hour) and eTower 2500 (200 tonnes

per hour).

The towers feature two systems for introducing

RAP – a recycling ring and direct introduction

in the mixer via an elevator. Their combined use

means that recycling rates of nearly 50% can

be achieved, while even higher recycling rates

can be achieved by equipping the plant with an

additional parallel dryer drum for RAP.

The eTower range has also been designed to be

able to gain from recent developments in warm-

mix asphalt production – a process that allows

asphalt to be produced at a lower temperature of

around 90°C to 150°C instead of traditional hot

mix temperatures of 140°C to 180°C.

Adding to the mix

Additives such as foam bitumen need to be

added to the mix to achieve quality warm mix

asphalt and Marini’s eTower 2500 is fitted

with its AQUABlack foam bitumen production

system, with the result that the final asphalt

temperature can be cut by more than 30°C,

claims the company.

Warm mix production has the obvious

Adding to

the mix

Increasing the use of recycled materials is a

key focus for the mixing technology industry.

Helen Wright reports

>

Marini’nin yeni asfalt tesisi eTOWER, %50’ye yakın

oranda geri kazanıma olanak tanıyor