international

construction

july-august 2014

50

MIXING TECHNOLOGY

Spin cycle

in support of operations. The largest project undertaken so far

has been in Kenya where concrete has been mixed for use in the

construction of a training facility.

Nurock’s technical teamworks closely with the Royal Engineers

to provide assistance and parts when required. The mixers are

expected to be in service for the next 10 years.

Twin technology

Italy-based manufacturer Simem offers a wide range of mixers.

The company is currently promoting its MDC and MSO

models.

The Simem MDC continuous flow mixer adopts twin shaft

technology and is especially designed for zero slump concrete

and RCC.

The MDC is offered in two main variants, MDC200 and the

MDC500. Options include side overflow discharge, extended

tank, stainless steel tank, and inflows for water or any other

materials.

The Simem MSO is also a twin shaft mixer. Available in

models ranging from 1 m

3

to 9 m

3

, the mixer is suitable for any

type of concrete, from wet to zero slump, with aggregates up to

200 mm in diameter.

All Simem models come with the company’s Mixer Mind

electronic check system, which monitors temperatures and

power consumption.

>

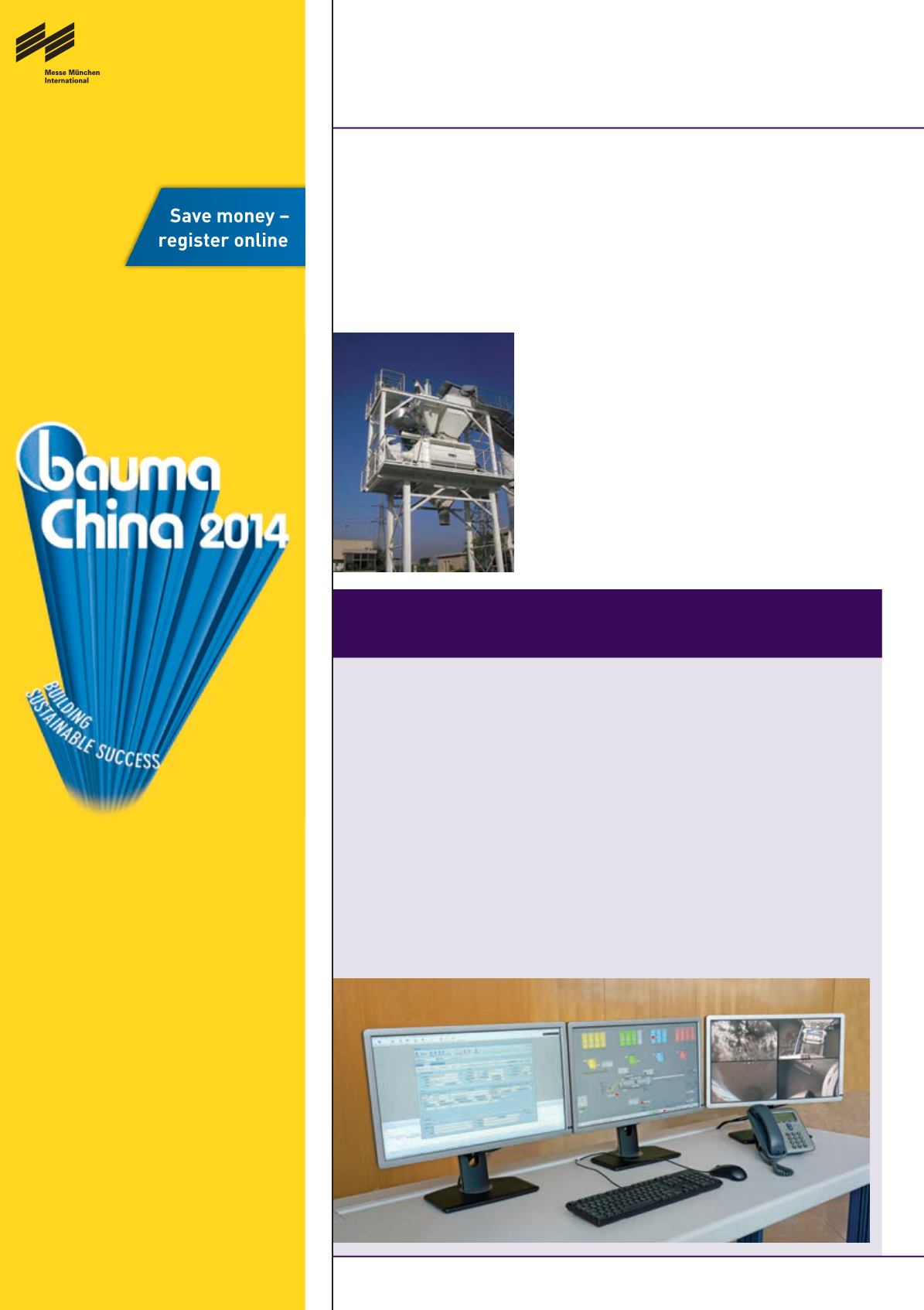

Liebherr takes control

Quick reaction times and maximum precision with MPS

L

iebherr has upgraded its MPS system for the control of concrete mixing plants. The software-

based Litronic-MPS III solution now provides a real-time capable operating system to manage

plant outputs and concrete quality.

The Litronic-MPS III provides a comprehensive overview of functions for the mixing technician to

provide uniform consistency in concrete production. The two-monitor control system provides data on

customers, material orders and concrete types on the left monitor, while the right monitor displays real

time interactive plant details.

The system comprises a computer, a four-channel precision amplifier, keyboard, two monitors, VPN

router for the Teleservice and a control panel with PC box and software. The PC box is equipped with a

ventilator and fine dust filter.

The Litronic-MPS III can be adapted for each plant. It can be connected to CAD/CAM processing

systems, remote access terminals and controls of bucket transport systems or gantry cranes. It is

also compatible with interfaces for concrete laboratory programmes such as Prolab, or with invoicing

programs.

For smaller plants the Litronic-MPS III LV microprocessor control can be operated with a single

monitor.

The software is available in 20 languages, with more languages under development or available on

request.

The Simem MSO

twin shaft mixer

is suitable for all

types of concrete,

from wet to zero

slump

November 25–28

SHANGHAI

NEW INTERNATIONAL

EXPO CENTRE

7

TH

INTERNATIONAL TRADE FAIR FOR

CONSTRUCTION MACHINERY,

BUILDING MATERIAL MACHINES,

CONSTRUCTION VEHICLES

AND EQUIPMENT