international

construction

july-august 2014

QU

AR

R

YING

42

Efficiency imperative

F

irst, look at underfoot conditions. W

ill

the machine work on a hard, rocky

surface, where tyre cutting will be a

threat?

In that case, you would want a tyre

with more rubber and less tread void, or a

higher net-to-gross pattern with a more cut-resistant compound.

Another factor to consider is the speed and distance that the vehicle will travel. This will

help determine if you need a more heat-resistant compound to handle longer hauls and higher

speeds.

Quarry operators should also consider the advantages of radial tyres versus bias tyres.

R

a dial tyres, in general, offer wider footprints and better fl

otation, plus greater resistance to

cutting and longer wear due to the more even distribution of pressure. A heavier bias sidewall

can provide more stable load conditions and possibly better sidewall cut protection. However,

it can run hotter than a radial.

Eric Matson is Goodyear’

s manager for global field solutions in the Off-The-R

oad (

OTR

)

.

continuously in reverse for asphalt applications.

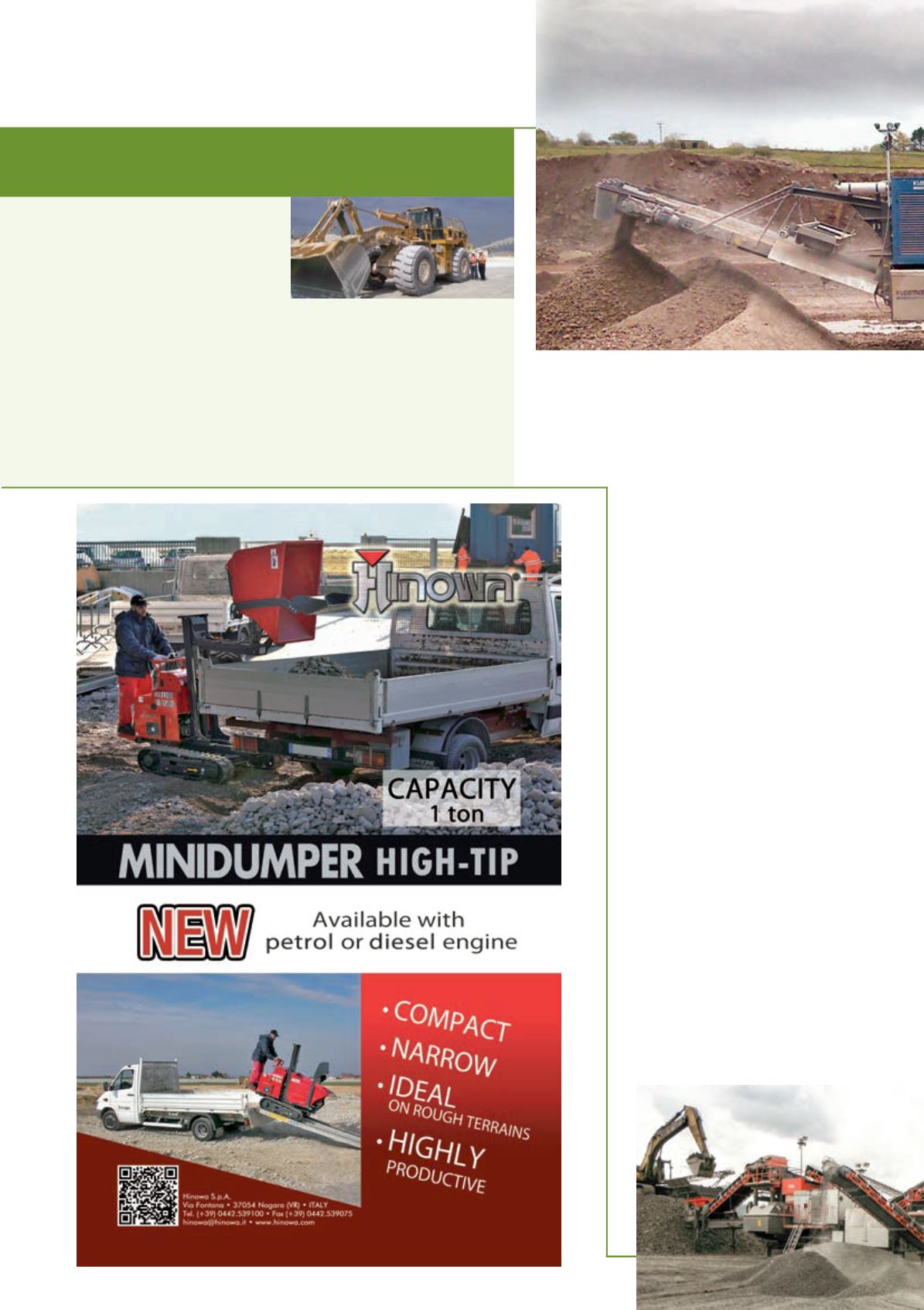

The Warrior 2100 screen comes with triple shaft technology to

maximise on efficiency and is especially suited to sticky scalping

applications. With amplitudes and accelerations in excess of 16

mm and 6 g respectively, the Warrior 2100 triple shaft screen

outperforms conventional screens in a multitude of applications

including aggregates, overburden, processed

ores, topsoil, compost, demolition waste,

foundry waste and biomass.

The mid-sized Maxtrak 1150 cone crusher

is offered in two configurations: a direct feed

model and a pre-screen version that enables

customers to handle dirty feed material and

achieve higher production rates. With a

choice of strokes and four liner options that

are all compatible with a single upper frame,

the Maxtrak 1150 cone crusher can be easily

configured for all applications.

The Premiertrak 600 jaw crusher comes

to market in two possible configurations:

diesel-hydraulic and diesel-electric. The diesel-

electric machine can be powered directly from

an on-site source. The unit boasts a 1,200 mm

x 820 mm modern jaw chamber including a

fully hydraulic closed side setting (CSS) range

of 75 mm-200 mm and a reversing system to

clear blockages.

Terex offers the complete crushing and

screening package. Its Terex Washing Systems

unveiled its Aggresand modular aggregate and

sand washing plant at the end of last year.

Aggresand has the ability to wash and

produce multiple aggregates and sands within

one machine, with a throughput of 250 tonnes

per hour.

The first Aggresand machine is now working

Burning rubber

Top tips for tyre selection for quarry equipment

The Sandvik UJ640 is a tracked jaw crusher

that has been purposely designed for the

global aggregates industry and features the

Sandvik CJ615 jaw