international

construction

july-august 2014

QU

AR

R

YING

40

Efficiency imperative

radio controls.” The new Metso MH-

series hammers and MB-series booms

include five boom-hammer combinations

for jaw crushers and one for primary

gyratory crushers.

Attachment manufacturer Montabert

meanwhile has launched a new heavy-

duty range of hydraulic breakers. The

V65 provides variable-speed technology,

automatically adjusting its impact energy

and striking rate to match material

hardness. Designed for use on large

excavators ranging in size from 50 to 80

tonnes, the 5.6-tonne hydraulic breaker

delivers up to 950 blows per minute.

Recommended for use in quarrying

applications, especially those involving fragmented, heterogeneous

materials, the breaker’s energy chamber acts as a hydraulic shock

absorber, reducing pressure variations in the hydraulic circuits to

provide consistent energy to the breaker.

Standard features include a progressive start system, a blank-fire

protection system and an automatic lubrication system.

Crushing & screening

German manufacturer Kleemann has seen strong demand for its

Mobirex MR 122 Z impact crusher, one unit of which is currently

in action at Grange Quarry in the UK.

One of the largest producers of aggregates and ready-mixed

concrete in the south of Scotland and the north of England,

Grange Quarry has been working with Kleemann for a couple

of years.

“Since 2012, we have been working successfully with a mobile

Mobicat MC 110 Z jaw crusher and we are really impressed with

the quality of the crushed end product,” said Stuart Dodd, owner

and managing director. The Grange Quarry uses the mobile plant

to crush whinstone for road construction, with a maximum feed

size of 600 mm to 125 mm at an output of around 200 tonnes of

crushed material per hour.

The new MR 122 Z impact crusher has been in use since

October 2013 and crushes limestone breccia of 600 mm down to

a final grain of 60 mm.

Blasting straight

New guidance system for straight blast holes

Also in the UK, a Kleemann MC 110 Z

EVO jaw crusher is being put to work on

the remote Shetland islands.

The island archipelago is currently

experiencing an oil and gas boom, as gas

fields are explored 125 km north-west

of the islands. In Sullom Voe on the

Shetlands the need for crushed stone is

rising rapidly to support this economic

growth.

EMN Plant. extracts a type of granite,

granodiorite, which is predominant in the

Scatsta quarry. The stone is naturally hard

and abrasive, which is why Ellis Nicolson,

a director at EMN Plant Ltd, invested in

a new jaw crusher.

The unit can crush a feed size of up to 1000 mm down to a grain

size of 100 mm in a cubic shape. The crusher can also process

recycled concrete.

“Our stone has a high level of fine grain. This is why we were

looking for a plant with good preliminary screening. Kleemann

provided an excellent solution with the MC 110 Z EVO,” said

quarry manager Craig Dickie.

Winning combination

In Nigeria, Asphalt Unity Construction now operates a Sandvik

mobile crusher and screening combination made up of a UJ640

jaw, together with US440i and UH640 cone crushers to work

alongside two QA451 Doublescreens.

The company specialises in crushing basalt and granite to be sold

to building contractors. The jaw and cone crusher combination

work to break down the materials to 25mm from a maximum

feed size of 975mm.

Asphalt Unity also operates a QA451 triple-deck Doublescreen.

The advanced triple deck system enables operators to make

changes to the drive, angling, vibration and meshes of each screen

box, which enables versatility in size and specification of the

finished products.

Powerscreen, part of Terex Materials Processing, launched

four new machines at this year’s Hillhead exhibition. New to

the catalogue are the Powerscreen Premiertrak 300 HA jaw

crusher, Powerscreen Warrior 2100 screen, and the Powerscreen

Premiertrak 600 diesel electric jaw crusher, which feeds the new

Powerscreen Maxtrak 1150 cone crusher.

The Premiertrak 300 jaw crusher features a new hydrostatic

drive system option allowing it to reverse and unblock or run

The Warrior 2100 screen includes Powerscreen’s

Triple Shaft technology, designed so the 16’ x 5’

screen box is highly effective and efficient while

maintaining exceptional throughput productivity.

>

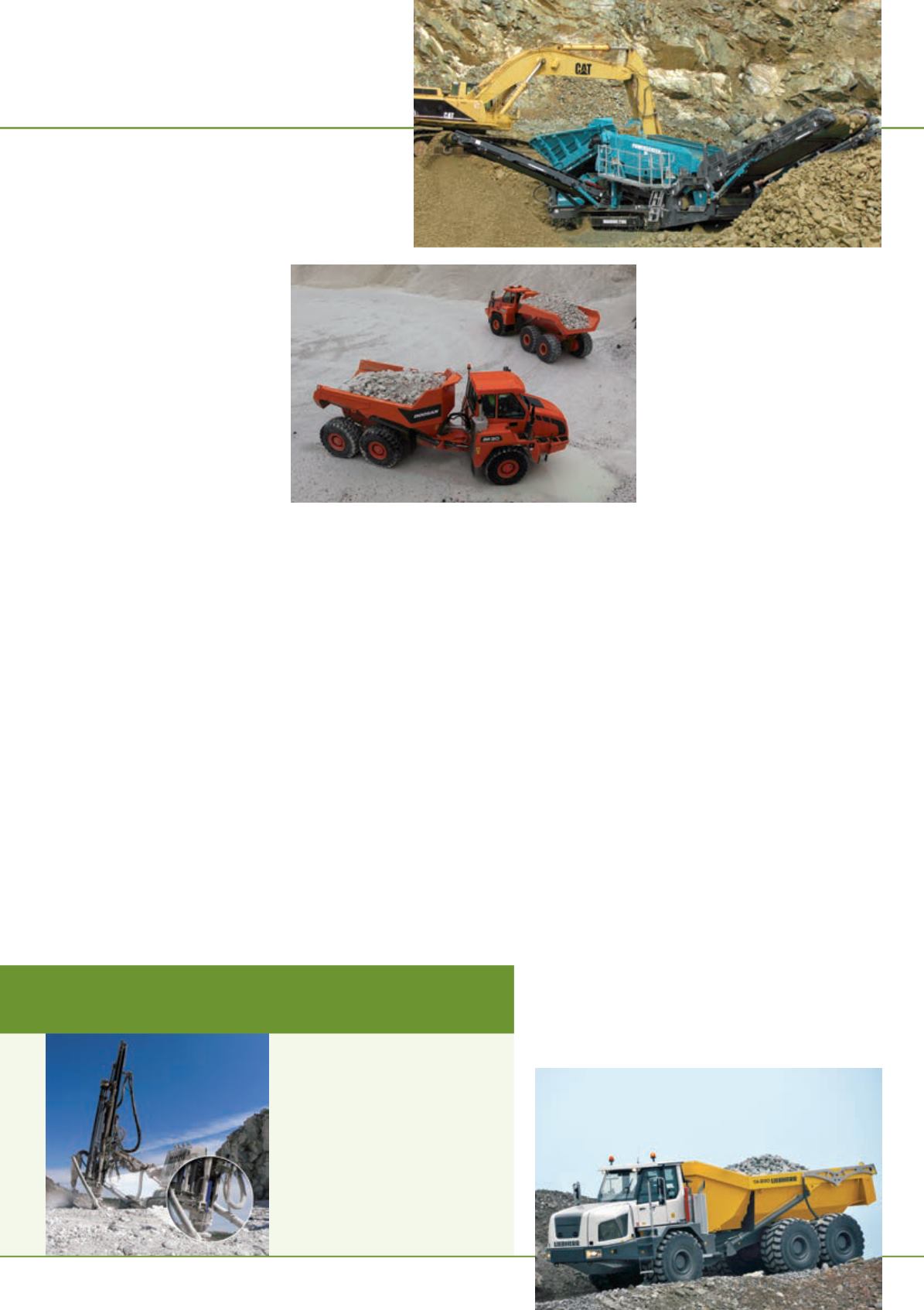

Doosan’s two

largest ADTs

now come with

Tier 4 final

engines, which

the company

says offer

fuel efficiency

savings.

F

innish manufacturer R

obit has

introduced a new product group for

creating straight blast holes. The line

consists of steel guide tubes and guide rods

with outer dimensions of 5

6

mm to 8

7

mm.

The lengths vary from 1.8

m to 6

.1 m.

The products can be used as single starter

tube to increase the straightness of the

holes or they can be used as a full drill string

in conditions where the rock is so broken

that a single starter tube is not enough.

Liebherr’s TA 230 Litronic articulated

dump truck has a transport capacity

of up to 33 tonnes