43

july-august 2014

international

construction

QU

AR

R

YING

Efficiency imperative

successfully in Dowling’s Quarry, Abbeyleix, County Laois in

Ireland where it is processing glacier sand and gravel material. The

Aggresand plant at Dowling’s Quarry is fitted with a 12 ft (3.6

m) double deck vibrating grid with 100 mm bofor bars and 50

mm woven wire mesh. This particular plant separates 0-40 mm to

the wash plant that gives three aggregate materials and two sand.

Ready to go

In the articulated dump truck (ADT) sector,

one of the latest machines on the market is

the Liebherr TA 230 Litronic, with a transport

capacity of up to 33 tonnes. According to the

manufacturer, the large dump body combined

with the robust drivetrain guarantee efficiency.

Even in the tough conditions encountered in a

quarry, the truck impresses with good driving

characteristics, and it is always safe when it is

on the move because of its efficient retarder

performance.

Komatsu’s latest ADTs, the HM300-3 and

HM400-3, offer an EU Stage IIIB engine

platform offering increased horsepower and

lower fuel consumption and emissions. The

Komatsu Traction Control System, along with

a new suspension and retarder system, helps

the vehicles stabilise on any ground.

The HM300-3 offers a maximum payload

of 28 tonnes, while the larger HM400-3 has a

capacity of 40 tonnes.

Meanwhile, UK manufacturer Bell

Equipment showcased its next-generation

E-series ADTs at Hillhead 2014: the new

B25E and B30E. Both come with a diesel

engine with Blu@dvantage technology to

provide high tonnes per litre ratios. On

board weighing is also standard, while Bell’s

Fleetm@tic system provides up-to date

operational data for desktop fleet management.

New additions from Doosan meanwhile are

the DA30 and DA40 articulated ADTs, which

are now fitted with Stage IV/Tier 4 Final

engines. Like all Doosan ADTs, the new DA30 and DA40 models

feature an articulation hinge positioned behind the turning ring

to provide equal weight distribution to the front axle even during

maximum steer articulation.

This together with a free-swinging rear tandem bogie ensures

equal distribution of weight to each wheel and guarantees

permanent 6-wheel contact and drive for equal power distribution

and excellent performance on difficult terrain.

Doosan says its new models offer best-in-class fuel efficiency

thanks to the use of new Scania engines and ZF EP transmissions.

The DA40’s body capacity has been increased to 24.4 m

3

,

enabling it to carry 40 tonnes without a tailgate, which is a +15%

increase on the previous model.

This illustrates the clear common theme throughout the

quarrying sector – whether it is new low emission machines for

Europe, Japan and the US, or equipment for lesser regulated

markets – that higher productivity and better fuel efficiency are

available with the latest generation of equipment.

iC

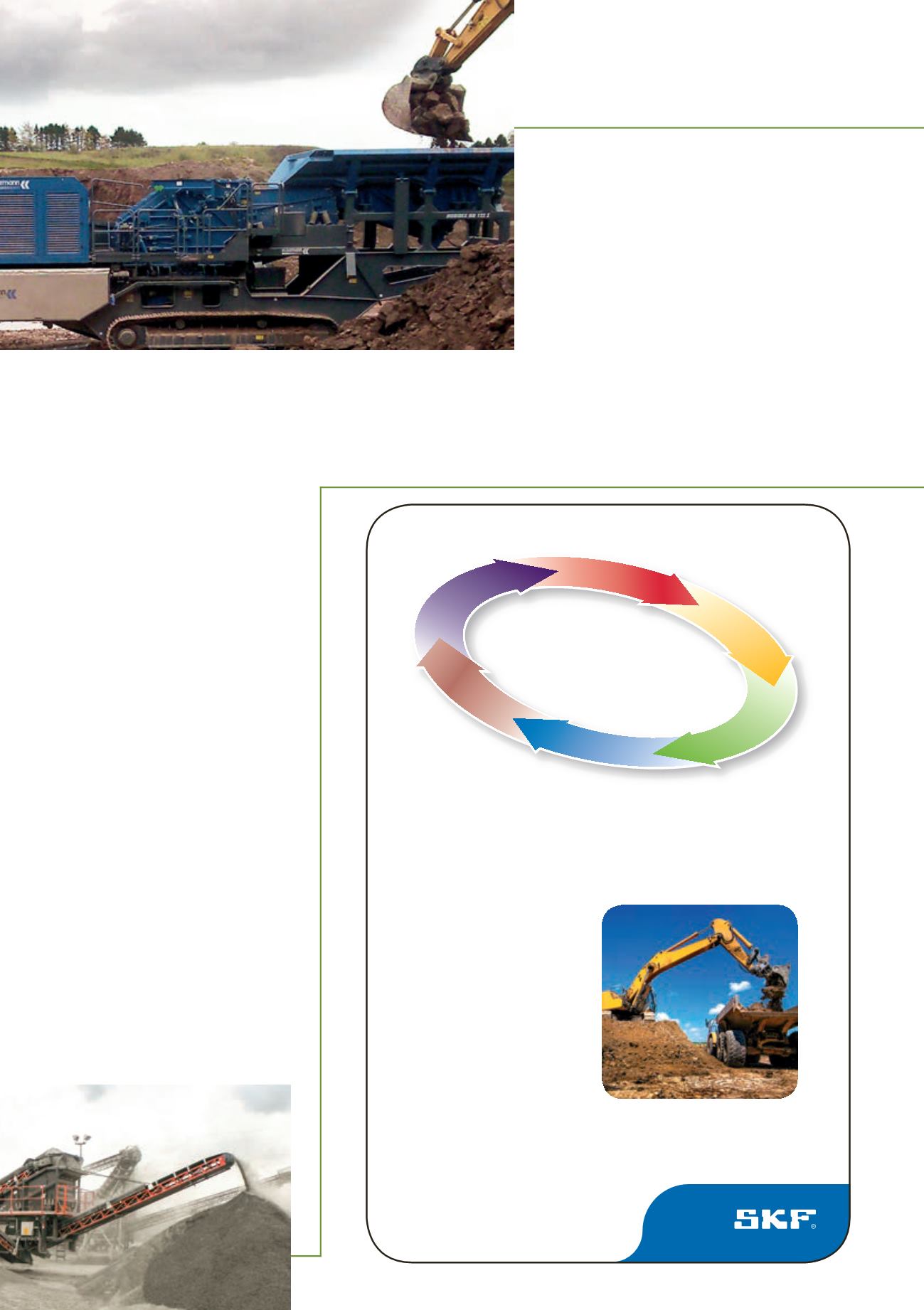

The new MR 122

Z impact crusher

from Kleemann in

action at Grange

Quarry.

I

n

s

t

a

l

l

a

n

d

c

o

m

m

i

s

s

i

o

n

O

p

e

r

a

t

e

a

n

d

m

o

n

i

t

o

r

M

a

i

n

t

a

i

n

a

n

d

r

e

p

a

i

r

S

p

e

c

i

f

i

c

a

t

i

o

n

D

e

s

i

g

n

a

n

d

d

e

v

e

l

o

p

M

a

n

u

f

a

c

t

u

r

e

a

n

d

t

e

s

t

SKF Life Cycle

Management

The Power of Knowledge Engineering

®SKF isa registered trademarkof theSKFGroup | ©SKFGroup2014

A “living” process for equipment optimization

Construction equipment OEMs and end users understand that

effective management of assets throughout their life cycle can

deliver significant value and reduce total cost of ownership.

SKF draws on decades of

construction application

experience and a unique mix

of products, tools, services

and technologies to help you:

• Improve productivity

• Reduce maintenance costs

• Improve energy and

resource efficiency

• Extend service intervals

• Optimize designs for

higher reliability

To learn more about SKF

solutions for the construction

industry, visit

skf.com/construction

or contact