53

july-august 2014

international

construction

MIXING TECHNOLOGY

Spin cycle

Asphalt

Asphalt provides even more challenges when it comes to mixing,

especially due to the rise in popularity of reclaimed asphalt

pavement (RAP) as a material..

Mixing asphalt and aggregate to make asphalt concrete (AC) is

all about temperature options. Hot mix asphalt concrete (HMA)

can see aggregates heated to as much as 150°C while the asphalt

is heated to just below boiling point, at 95°C. This is favoured

for high-traffic paving, such as highways and airport runways.

Warm mix asphalt concrete (WMA) is made by adding

zeolites, waxes, emulsions or water in the mixing process. This

is a more eco-friendly option as it uses less energy and produces

fewer emissions and carbon dioxide.

Mixing the asphalt with water and soap, before adding the

aggregate, produces cold mix asphalt concrete. Cold mix is most

often used as a patching material and on less busy roads.

US-based asphalt plant manufacturer Astec launched a number

of new product lines at the ConExpo-Con/Agg exhibition

earlier this year.

The manufacturer has increased the ability of its signature

Double Barrel drum dryer/mixer to handle RAP. The Double

Barrel HR includes enhancements to the drum which allows

use of up to 65% RAP. The company also offers its 100% RAP

plant – the RAP King.

Astec president Malcolm Swanson said, “The Double Barrel

HR is a key product in the Astec line. It fulfils a need for those

producers who already run high percentages of RAP and in

whose markets the trend toward running more RAP is expected

to increase.”

Astec also introduced its 120 tonne per hour Voyager plant.

The Voyager 120 has the ability to run up to 30% RAP and

offers a compact, highly portable design.

The Voyager 120 is built around a counter flow drum featuring

Astec v-fights. The v-flights provide greater uniformity of the

aggregate veil during the drying process, which results in better

heat transfer, a reduction of fuel use and increased productivity.

To enhance portability, a hydraulically driven swing out drag

and batcher can be set and ready to go in 10 minutes. Other

features include a reverse pulse baghouse, a control cab with

fully automated PLC controls, gravity take-up with direct

drive, air ride suspension and up to five cold feed bins and two

RAP bins.

On the rails

High output concrete train

N

urock’s cement mixers have proved an integral part in Network Rail’s North

West Electrification Project between Liverpool and Manchester, as the railways

operator installs 25 kV overhead power on the lines between the two cities.

The UK manufacturer created a bespoke High Output Concrete Train (HOCT) for the job.

Created from Nurock’s 7-m

3

truck mounted mobile concrete catching plant, the HOCT

was designed to comply with rail gauges and tunnel heights.

The HOCT carries sand, aggregate, cement and water in separate compartments,

mixing them on demand to reduce waste.

“The HOCT has just finished phase 2 of electrification works between Liverpool and

Manchester. It’s been operational for two years successfully supplying concrete six nights

a week,” explained Graham Jones, managing director of Nurock Mixers.

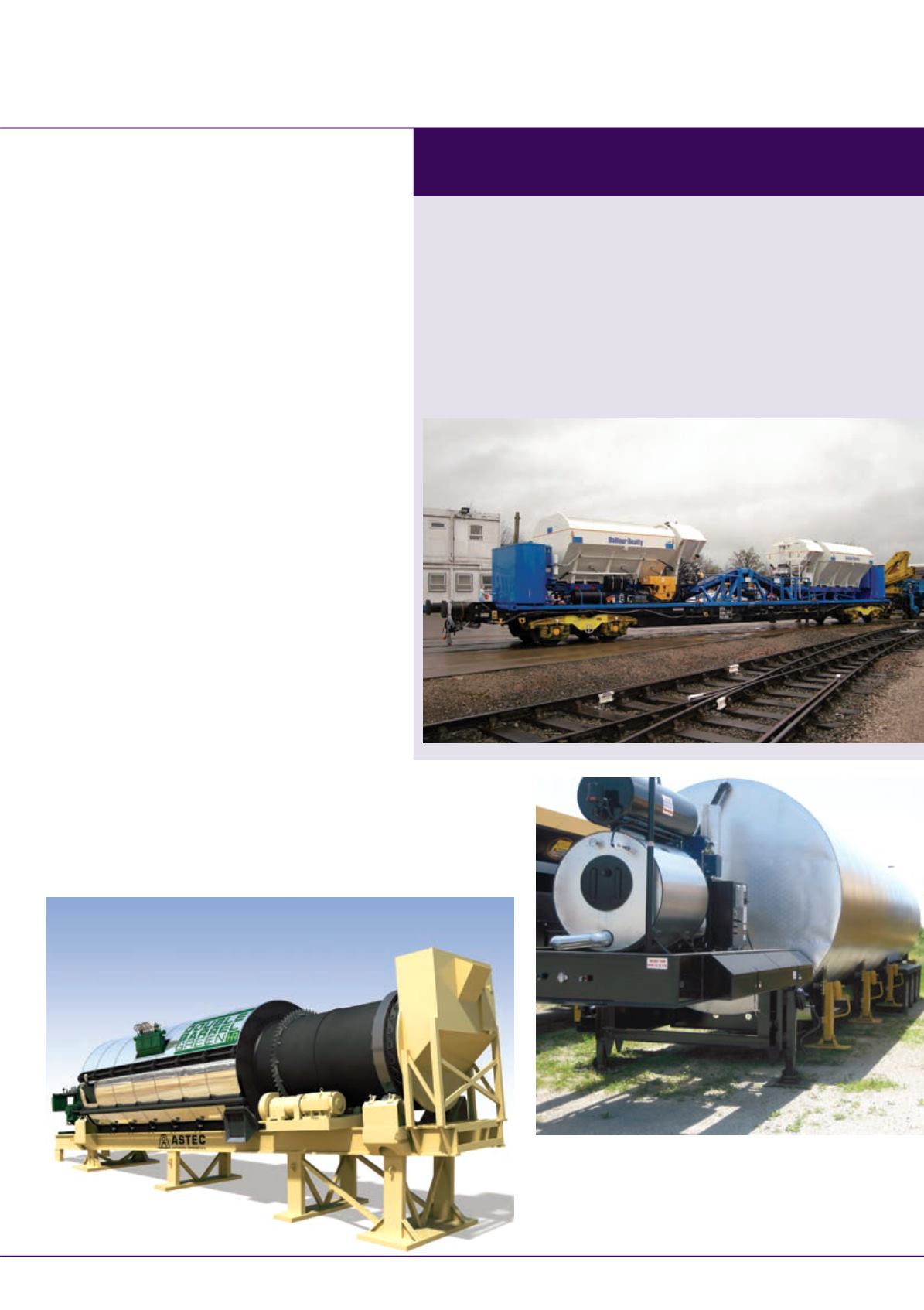

The Astec Double

Barrel HR allows

producers to use

up to 65% RAP

in mix

ADM’s AC tanks

are available

in vertical and

horizontal/

portable

configurations

>