59

EQUIPMENT

july-august 2014

international

construction

TEREX

Tipping point

T

erex AWP, better known by

its brand name Genie, has

had a presence in China

since the mid-1990s. It started

out selling big telescopic boom

platforms to Chinese shipyards,

building its business up to a

point in 2010 when it opened a

dedicated access platform factory in

Changzhou.

It is a mark of how far the

business has come that today the

Changzhou factory is Genie’s global

production centre for shipyard

booms. On the regional level, it

also builds numerous other models

for sale throughout Asia-Pacific and

of course has a big focus on the

potentially huge Chinese market.

Despite a continued slow-down

in the Chinese construction

market, the ramping-up of

production for the wider region

has seen big changes over the last

year at the 278,000 ft

2

(26,000 m

2

)

facility, as general manager Clint

Weber explained.

“If you were to compare last year

to this year, we have brought in 15

models that we are building instead

of importing now,” he said. “We’ve

had good growth, but it’s not just

China. Changzhou supports Asia-

Pacific now, so it’s a much bigger

piece of the pie.”

This has seen the facility’s

workforce swell from 140 staff a

year ago to more than 210. But it

People in the powered

access industry talk

about new territories

reaching a turning

point, when suddenly

the concept takes root

and the market takes

off. Genie believes that

moment could be just

around the corner in

China.

Chris Sleight

reports.

is not just about more people on

the production side. There is also

a design capability in Changzhou,

and one of the priorities at the

moment is to localise the products

more to take out costs.

“We have a strategic plan, and

the point is that anything we do to

take cost out will be imperceptible.

We are maintaining the global

standard of our machines. If we

were to localise a component

or weld something in house, it

has to pass all the rigours of the

Genie Engineering Standards

that we have, which are difficult

to pass, rightfully so. There are

opportunities to take cost out, but

we’re not going to go to the lowest

of the low.

“It has to be imperceptible. You

won’t be able to see the difference

between our machines and those

made in Redmond (Genie’s home

facility in Washington state, US).

There might be slightly different

components, but those components

will be interchangeable. If you

have one component and it won’t

fit on another machine, then that

becomes a different machine. When

we’re exporting to Asia-Pacific and

the rest of the world, that becomes

important,” said Mr Weber.

While the Changzhou plant has

come to establish itself as Genie’s

regional hub for Asia-Pacific, the

big prize is of course China, which

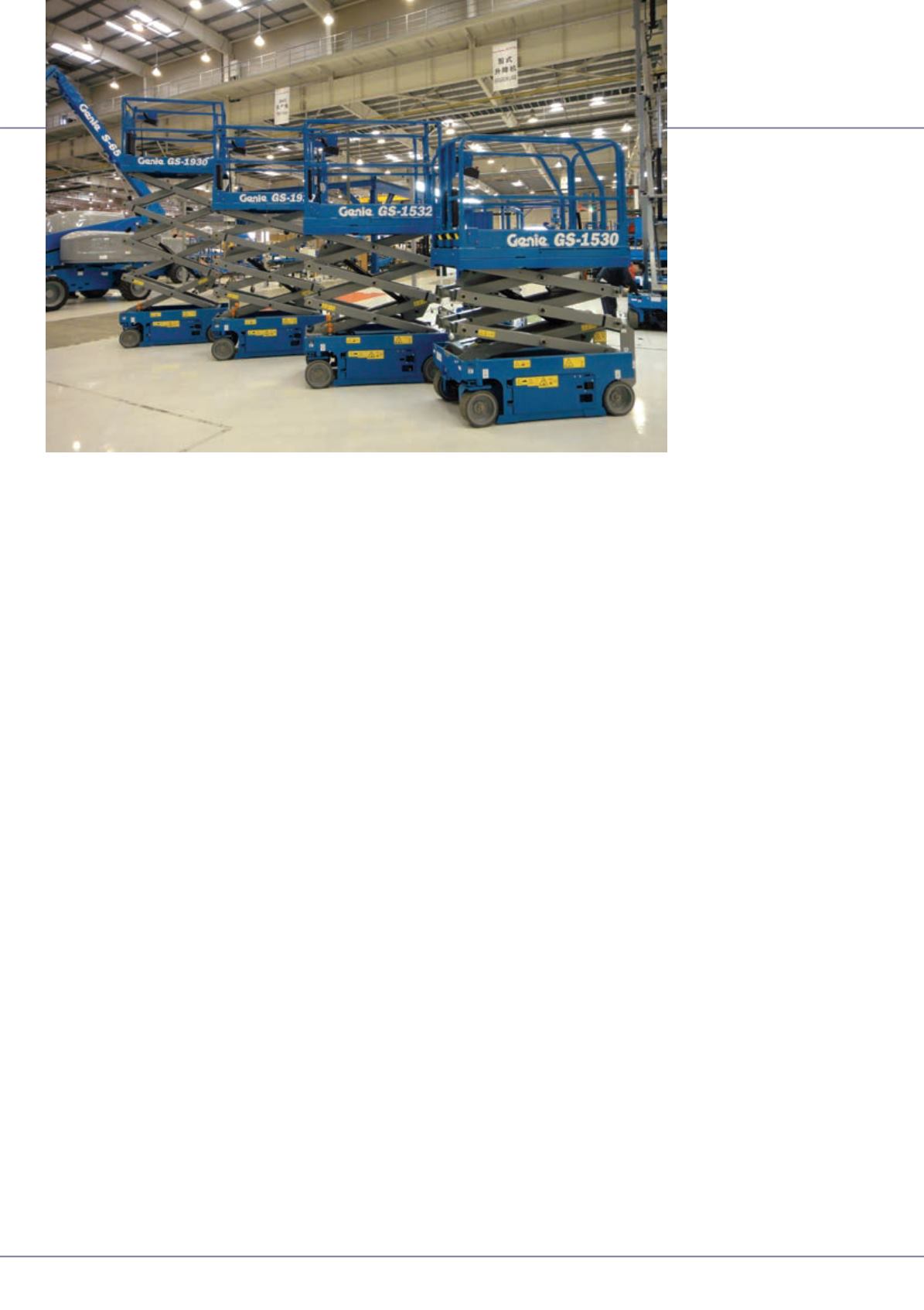

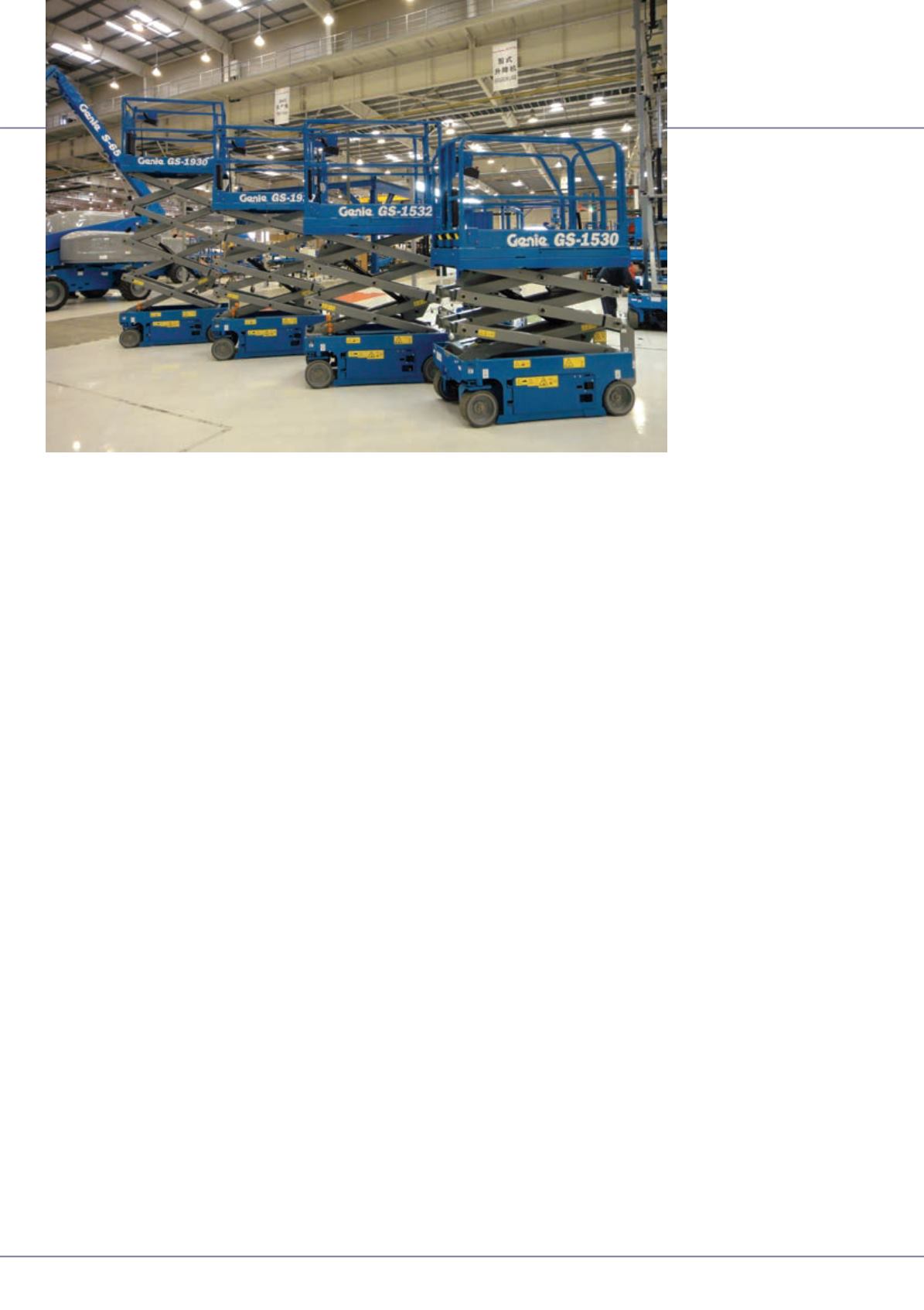

Genie’s Changzhou, China factory is now making

eight scissor lifts per day, among other products.

is by far the biggest construction

equipment market in the world

in unit terms. But although

staple construction machines like

excavators and loaders sell in the

hundreds of thousands per year

in China, access platforms are far

from enjoying the same level of

acceptance.

Tipping point

It is a pattern that has been

reflected in many countries around

the world over the years, and

those close to the industry observe

that after many patient years of

introducing products and educating

the market, powered access

eventually tends to take off. This

tipping point is just around the

corner according to Jim Barr, Terex

AWP’s vice president and general

manager for Greater China.

“Obviously everybody’s waiting

for that exponential growth that

happens in new markets. In Korea

it happened in 1999, Singapore

happened in the early 1990s and

Australia happened around 1988.

There’s an inflection point and

China feels very close to that, at

least from my experience in the

marketplace,” he said.

One of the curious things about

this is that platform sales in China

are on the up at the time when

the wider construction equipment

industry is suffering a third straight

year of contraction, following the

huge stimulus-spending boom of

2009 to 2011.

Mr Barr acknowledged this. “It’s

going from strength to strength,

but at the same time we’re cautious.

A lot of the key elements in the

marketplace are there for that

inflection point. A huge project

might push it, or a change in safety

rules - which is what happened in

Brazil and Singapore. There’s going

to be something that pushes it over

the top.”

He continued, “This is my take

on the marketplace. You have

construction at the centre and

you have three key elements –

safety, availability of product and

efficiency & productivity. Right

now in China, safety is coming.

We have a reduction in scaffolding.

I don’t see it as being forced – it

seems to be organic as more aerial

work platforms become available.

Social pressure is there and the

standard of living is increasing. You

see in every emerging market that

as the standard of living improves,

people are more concerned about

safety.

“None of this will happen unless

there are affordable products in

the marketplace. Contractors need

to be able to look at projects and

say ‘I’m going to bid this based on

19 ft scissors or 32 ft scissors.’ We

have professional rental in place

>