international

construction

april 2014

TUNNELLING

46

Unique challenges

backwards and forwards to handle up to 1,000 tunnel lining

segments.

Falsework& formwork

Meanwhile, several falsework and formworkmanufacturers have

added specialist tunnel formwork to their portfolio. Alsina, for

instance, offers a self-supporting formwork system that ismoved

by a hydraulically-driven carriage along a tunnel, allowing the

use of several formwork systems to line a tunnel.

Another method for tunnel building is Alsina’s Modular

Curved formwork for the construction of false tunnels and

tunnel entrances. This system supports a maximum pressure

of 60 kN/m

2

, requires a minimum bend radius of 2.5 m and

allows a modulation of 2.4 x 2.4m.This means it is adaptable

to different radii, while Alsina said it also facilitated quick and

securemounting, boosting productivity.

For its part, Doka used different techniques to support

construction of four tunnels during the building of the

€ 718 million (US$ 996 million), 22 km S 10 highway in the

Mühlviertel district of Austria.

These included itsmodular heavy-duty supporting systemSL-1

in combinationwith the large-area formworkTop 50 and high-

capacity hydraulics, and its new cut-and-cover tunnel formwork

system, Doka CC. This system supported construction of

both tubes of the Pernau Subsurface Tunnel, each of which is

270 m long. The formwork can be adapted to the complex,

slightly rotating geometry of the structure.

Doka CC also supported construction of the Ganglsiedlung

SubsurfaceTunnel,whichconsistsof two tubes, each275m long.

The manufacturer said adaptation to the structural geometry of

this tunnel required little additionalmaterial cost.

Ambitious

The tunnelling sector is busy and ambitious, with a range of

very large infrastructure projects currently underway around

the world. Of course it is ideal when everything runs smoothly

and projects are completed on schedule, but the sector’s ability

to overcome unforseen challenges like TBM breakdowns also

speaks volumes about the ability to solve problems.

iC

Qatar mega project

Work is ready to get underway on planned newmetro network

T

he first of 15Herrenknecht EPB TBMs has just been built and is ready to start work on

the newmetro network inDoha, Qatar. By 2019, they are planned to drive about 90 km

of tunnel through the limestone below theQatari capital for theRed Line South, theRed

LineNorth and theGreen Line.

Further plans envisage the completion of a second section of themetro by 2026. The

completed networkwill have four lines and around 100 stations, connecting the residential

and business centres of the capital with each other and the suburbs.

The first five EPB TBMswill be used to drive 34.7 km of 7m diameter tunnels through

limestone for theRed Line South. The contractor for this part of the project is a joint venture

betweenQatari Diar, Vinci ConstructionGrands Projects (QDVC), aswell as GS Engineering&

Construction andAl Darwish Engineering.

TheRed Linewill not only handle the bulk of the national transport and connect themost

important stadiums of the football World

Cup in 2022. As a central line it also

connects the city centrewith the airport and

theWestbay Central.

L to R, former German Chancellor

Gerhard Schröder, Herrenknecht

chairmanMartin Herrenknecht and

Qatari Transport Minister Jassim Saif

Ahmed Al Sulait.

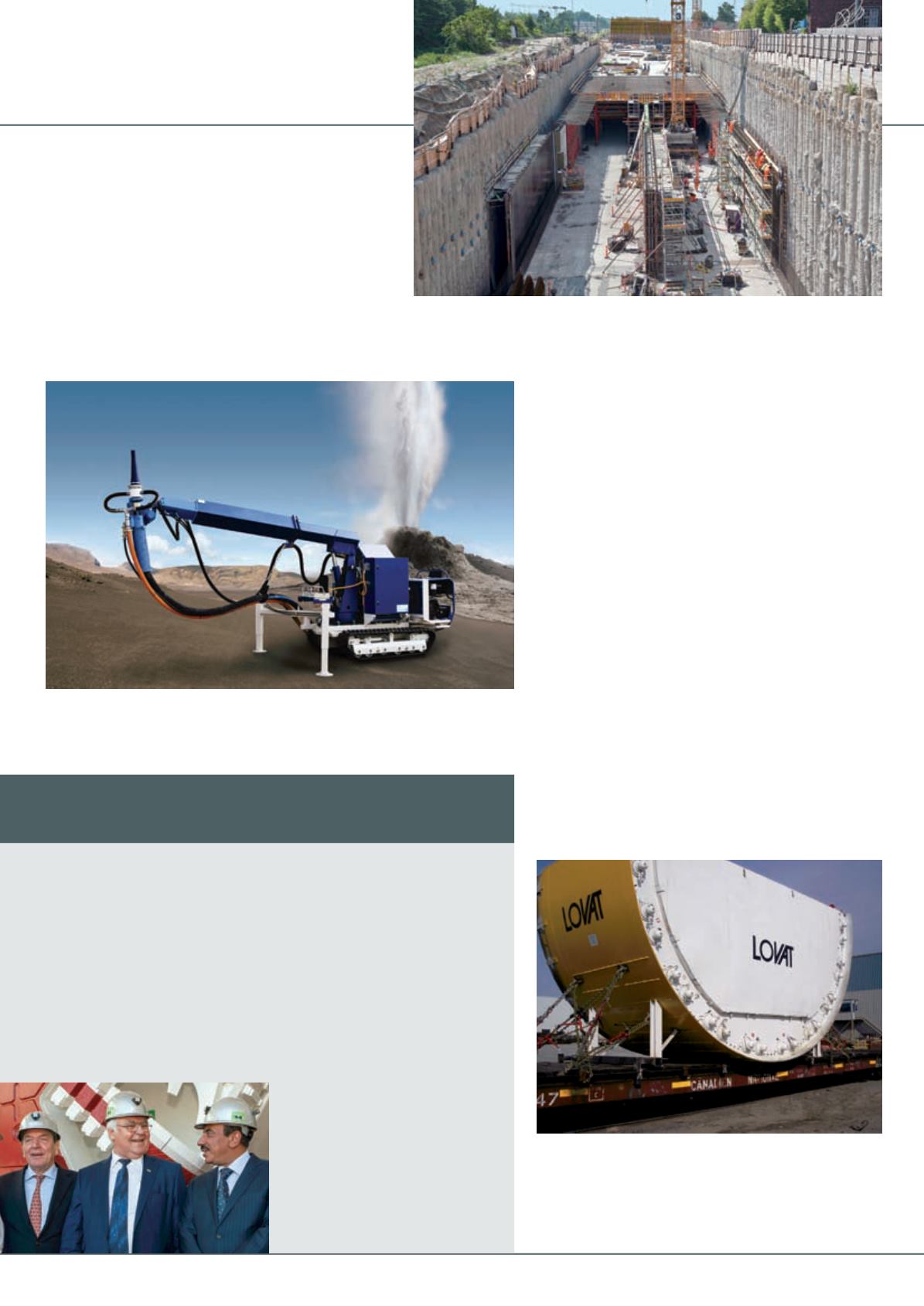

The new 620m long Nordhavensvej road tunnel in Copenhagen, Denmark, is

being built using the cut-and-covermethod. Thewalls are concreted against the

up to 25m deep bore pilewall. Following this, the 80 cm slab is concreted using

Peri’s Variokit slab formwork carriage.

Eight Meyco Shotcreting units fromAtlas Copco are supporting construction of

the Tottenham Court Road underground station in London, UK. These include three

Suprema units for shotcrete pumping, three Oruga units (pictured) for general

sprayingworks, and two Piccola units for dry spraying.

Caterpillar is to sell the assets of Caterpillar Tunnelling

Canada Corporation to Chinese company Liaoning Censcience

Industry Co., Ltd. InMay last year, Caterpillar said it planned

to exit the sector and close the operation – formerly known

as Lovat, which it acquired in 2008. The new deal is expected

to close in the third quarter of 2014.