45

april 2014

international

construction

TUNNELLING

Unique challenges

>

The US$ 3.1 billion tunnel is a replacement for the Alaskan

Way Viaduct, and was initially scheduled to be completed by

September this year, and operational by December 2015. The

difficulties being faced by Bertha serve to highlight how critical

the smoothprogressofTBMs are to thecompletionof tunnelling

projects.

New tools

Elsewhere in the sector, manufacturers continue towork closely

with contractors to boost productivity and safety, developing

customised equipment from new excavation units to flexible

formwork designs.

GTAMaschinensysteme, for example, specialises in building

machines that run on monorails for use in tunnels. It has

introduced two new machines designed to support specific

aspects of tunnel lining and excavation.

Thefirst is amultifunctional uphill excavator, developed for the

Crossrail metro project in London, UK – currently the largest

infrastructure project inEurope (see box story).

GTA said the machine was designed and produced in six

months, andwas introduced inOctober last year.While themain

tunnels for the Crossrail project are driven byTBMs, secondary

incline shaftsneed tobedugout to connect theCrossrail stations

to the new subway lines. The idea is that escalators will be

installedhere once complete.

These incline shafts are being driven from TBM-level to

subway-level (bottom upwards), and GTA said the 30

o

tunnel

incline was not possible to tackle with floor-bound machines.

The uphill excavationmachine and its working platform are also

suspended on two overhead monorail tracks, and moved along

byGTApush-pull units.

Themachine features four breaking trolleys to keep it safe and

secure at steep inclines, and digs forward using a specialised

shovel. It alsoboasts adrill feed andbeused todrill blast holes in

case hard rock ismet, aswell as a hydraulic hammer for breaking

up rock, and a nozzle and lines for shotcreting.

Another new machine from the manufacturer is the TAM

7500A liningmachine for subway tunnels–apieceof equipment

developed with the idea of mechanising the installation of cast

iron or steel tunnel lining segments.

TheTAM7500A is a28 tonnemachine,

also suspendedon twooverheadmonorail

tracksmounted on the inside of a tunnel.

An additional rail track is suspended at

the side and is used as travel rail for the

transport unit. The machine has two

booms which are separately mounted in

two guideways, where they can bemoved

Crossrail’s 8th TBM launches

Progress on largest construction site in Europe continues

T

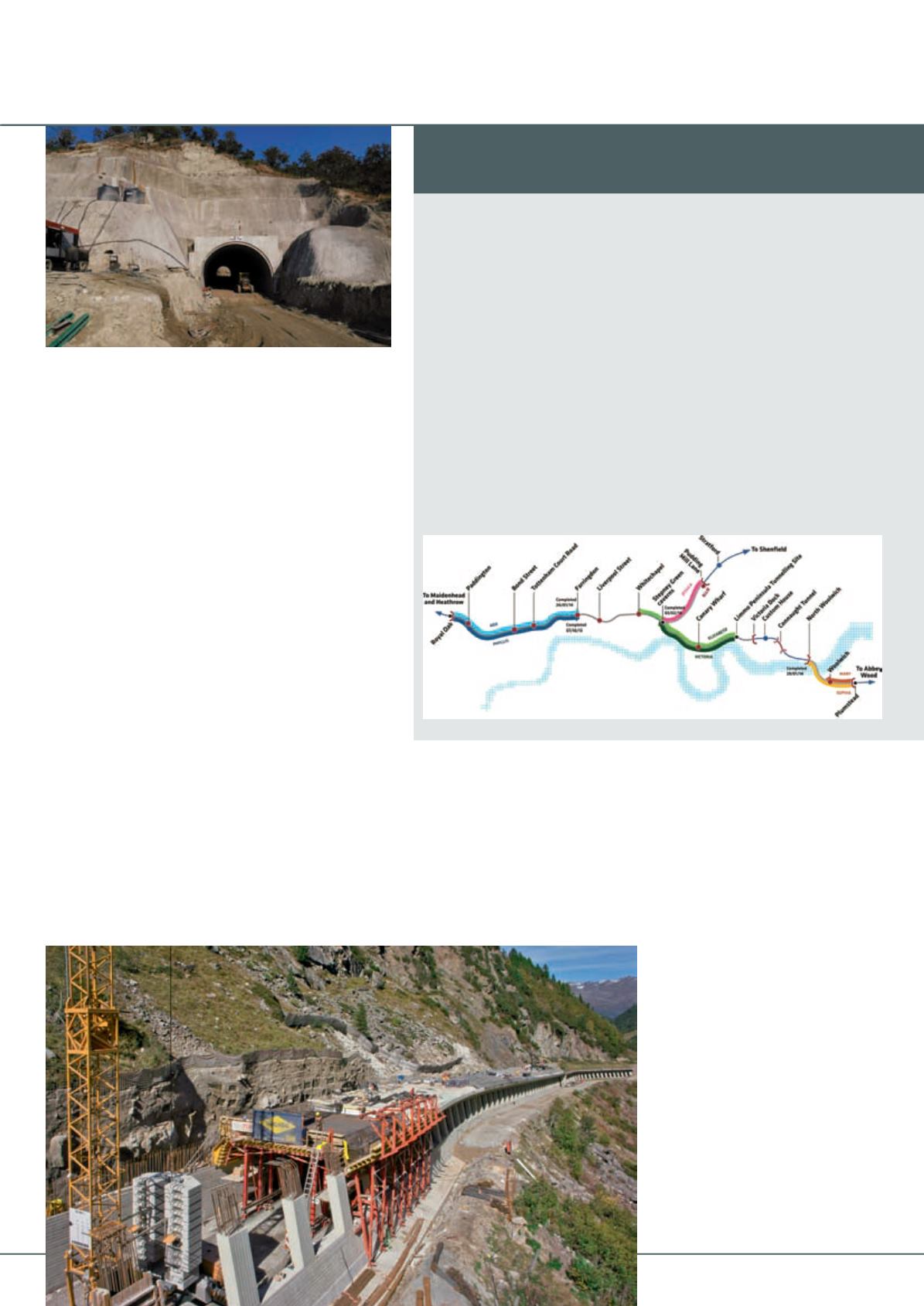

heUK£ 14.8 billion (US$ 24.6 billion) Crossrail metro project in London, UK– the

largest construction site in Europe – is progressing quickly, with the eighth tunnel

boringmachine (TBM) launched in February.

Developer Transport For London is building the project, whichwill pass through 38 stations

and run fromMaidenhead andHeathrow in thewest of the country’s capital to Shenfield and

AbbeyWood in the east.

Manufactured by Herrenknecht, TBM Ellie began its 2.7 km journey fromPuddingMill

Lane to Stepney Green in London’s East End on 25 February, at depths of up to 30m below

ground. The tunnel will form part of Crossrail’s north east spur fromWhitechapel to Shenfield

in Essex.

At 150m long and 7.1m in diameter, Ellie is staffed by 20 people andweighs 1,000

tonnes. Its sistermachine, Jessica, completed the journey fromPuddingMill Lane to Stepney

Green on 3 February, and in the comingweekswill be taken to Limmo Peninsula near

Canning Town in east London, where shewill beginCrossrail’s last tunnel drive towards

VictoriaDock Portal.

Crossrail recently passed the halfway point in its construction, and is said to be on time and

within budget. Over 30 km out of 42 km of bored tunnels are now complete. The eight TMBs

will construct ten different tunnels, with tunnelling 70% complete.

A customised Variokit tunnel formwork

solution from Peri is said to have sped

up construction on the 228m long

Marchlehner gallery on a road situated

at a height of 1,800m above sea level

in Austria. The gallery is designed to

provide protection against avalanches

and falling rocks.

Sandvik DT820 tunneling jumbos supported contractor Afcons

Infrastructure in redeveloping India’s 65 kmNational Highway

1, a US$ 350million project that included four twin tube

tunnels through the Himalayanmountains totalling 1.5 km.