international

construction

april 2014

EARTHMOVING

38

Reducing the burn

they nowmeet Tier 4 Final emissions standards. It highlighted

the fact that its DPF cleaning process occurs automatically with

no impact tomachine operation, andwith anup to 15,000hour

service interval.

It said ithadensured that integrating theTier4Final enginehad

not affected visibility for the G Series, which range in operating

weight from the 19 tonne class 670G/GP to the 21 tonne class

872G/GP. In addition, it integratedLEDwork lights to the new

models, while its telematics technology – JohnDeereWorkSight

– also comes as standard.

And another new grader has been released by Volvo, the

Tier 4 Final-compliant G946C. This 17 tonne class machine

features technology including load-sensing hydraulics and an

all-wheel drive system with creep mode, which only engages

the hydrostatically-powered front wheels for fine grading

applications.

If required, theG946Ccanalsobefittedwitha third-partygrade

control system, using the Technology Ready Option. Volvo has

developedacommon interfaceand installationpackage toensures

high productivity and precision in fine grading applications,

regardless of customer preference.

Advantages

Ithasclearlybeenabusy time for theearthmoving sector, andwith

fuel consumption savings of asmuch as +25% being claimed on

some of the latestTier 4 Final models, there are clear advantages

to the latest engine and transmission technology for end-users.

However, now that the Tier 4 Final laws are in place, forcing

all the sector’s manufacturers to install new engines, it will be

interesting to see where manufacturers invest their research and

development funds next.

A trend seems to be for automating more andmore functions

and further integrating machine control and telematics

systems, targeting further increases inproductivityandequipment

security.

Volvo, for instance, said one area of technological development

that it is looking into is machine-to-machine and machine-

to-infrastructure communication. This is also an area being

emphasised by pure technology companies in the sector like

Leica,Topcon andTrimble.

“One of the advanced engineering projects we’re working on is

wireless machine communication technology,” said PeterWallin,

research coordinator at Volvo CE. “By increasing machine

intelligence and making it possible for machines to ‘talk’ to

each other we can reduce operational costs through improved

fuel efficiency, while also increasing safety and maintaining

productivity.

“So far we’ve looked at the quarry and aggregates segment and

road construction – but this technology can be used in all the

applicationsVolvomachineswork in.”

iC

Managing data streams

New technology is being developed to help combat downtime

T

elematics systems are reaching every corner of the construction equipment industry,

allowing end-users and dealers tomonitor the status of a fleet of machines in real-

time. However, Grathwol Automation claims there is a flaw in the current evolution

of the real-time telematics diagnostics picture –what happenswhen themachine has

stopped?

It has launched new technology dubbed IntelliMaticswhich has been developed to

showwhy an enginewill not start and/or why other production systems on themachine

have stoppedworking. These includewhy the upper conveyor won’t operate on amilling

machine or why the screedwon’t move

on a paver.

The device –which can be installed in

old and new equipment and is powered

from the vehicle’s electrical system – also

provides a visual guide so the operator

can seewhere the voltage path stops

in the circuit under test and create

customised fault codes for themachine,

not just the engine.

Hyundai’s prototype R220LC-9 HI-POSS excavator features

its Hyundai Intelligent Power Optimal Sharing and Energy

Saving (HI-POSS) system. This is said tomaximise energy use

through an electronically-controlled pump and valve, rather

than the conventional spool-operated valve. Fuel savings of

up to 20% are expected as a result of this technology.

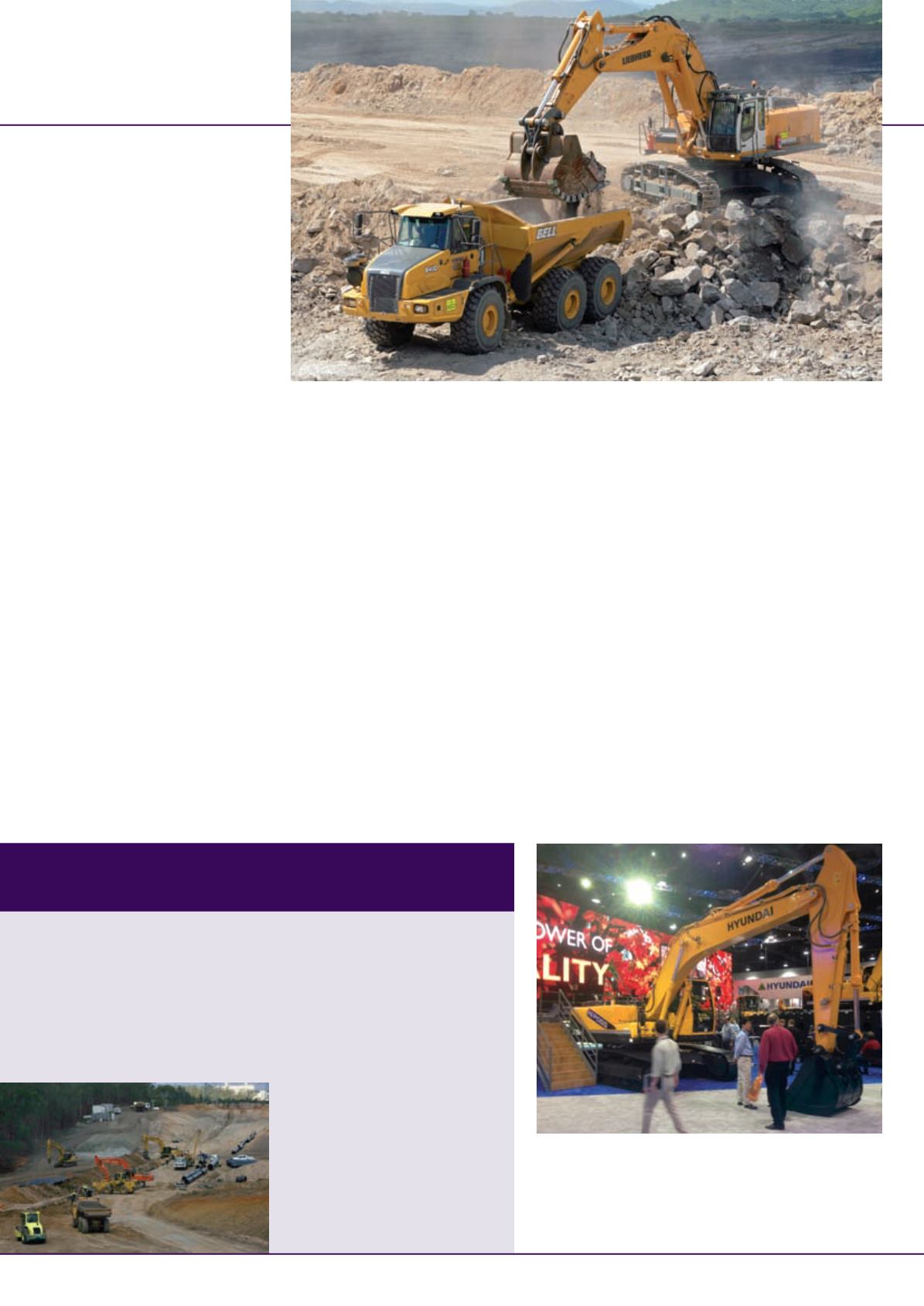

Contractor TayannaMozambique

bought four Bell B40DADTs and a

Liebherr R964C excavator, a Bell

770G grader and a Bell 315SK 4x4

backhoe loader for a range of hauling

and earthmoving tasks, including

building earth bridges spanning rivers

for abnormal loads on the road to the

Cahora Bassa hydro-electric scheme

inMozambique.