38

CONSTRUCTION EUROPE

SEPTEMBER 2013

COMPACT LOADERS

The LX-cab is a lighter version, and particular

attention was given to enhanced visibility for

the operator, said Avant. The door and the

side window can be removed and the new

design of LX-cab offers more space within the

cab for the driver.

Avant’s loader range has also expanded

with a new R-series featuring two newmodels

– the R28 and R35. The R-series is different

from other Avant models as the cab is located

on the back frame instead of the front frame.

Jani Käkelä, vice president Avant Finland,

said, “With the new models, we want to

provide the benefits of Avant loaders also

to those customers who are used to driving

the loader with the cab located on the back

frame.

“Our aim is that the R-series driving

experience should be similar to a typical

Avant loader.”

The new models are based on the existing

Avant 528 and 635 models. “You can really

notice the driving benefits of R-series in small

spaces and tight corridors,” said Mr Käkelä.

“Although the turning circle is itself exactly

the same as the familiar sibling Avant models,

the new R-series loaders are easier to reverse

in tight spaces because the cab in these

loaders will not turn outside the tyre line.”

LOAD STABILITY

The L60G, L70G and L90G from Volvo

Construction Equipment in the 11 to 15 tonne

class, claim that their loader arms’ patented

TP linkage offers superior breakout and lifting

forces, while also remaining perfectly parallel

throughout the lifting range, which ensures

load stability.

Volvo said the combination of power

throughout the lift cycle, parallel movement

and long reach made the models suitable

where fast work cycles are needed. It said

the D6 engine also led the industry in terms

of fuel efficiency, reliability and noise. The

production of torque and power at low

engine speeds, combined with load-sensing

hydraulics, removed the need to overrun the

engine, said Volvo, which in turn extended

engine life, lowered fuel usage and reduced

noise.

Fuel use and noise are also reduced, thanks

to a hydraulically driven, electronically

controlled fan, which is only activated when

needed.

Volvo claimed that load-sensing hydraulics

delivered power to hydraulic functions only

when needed, eliminating unnecessary oil

pumping.

Volvo’s L45G and L50G wheeled loaders are

in the 9 to10 tonne class of machine – but are

said to have the versatility and performance

of much larger models.

They also feature Volvo’s TP Linkage. It

claims high tilt-back torque and lifting power,

which Volvo said increased productivity when

loading or rehandling.

Smaller in size than many competitor

machines, these models’compact dimensions

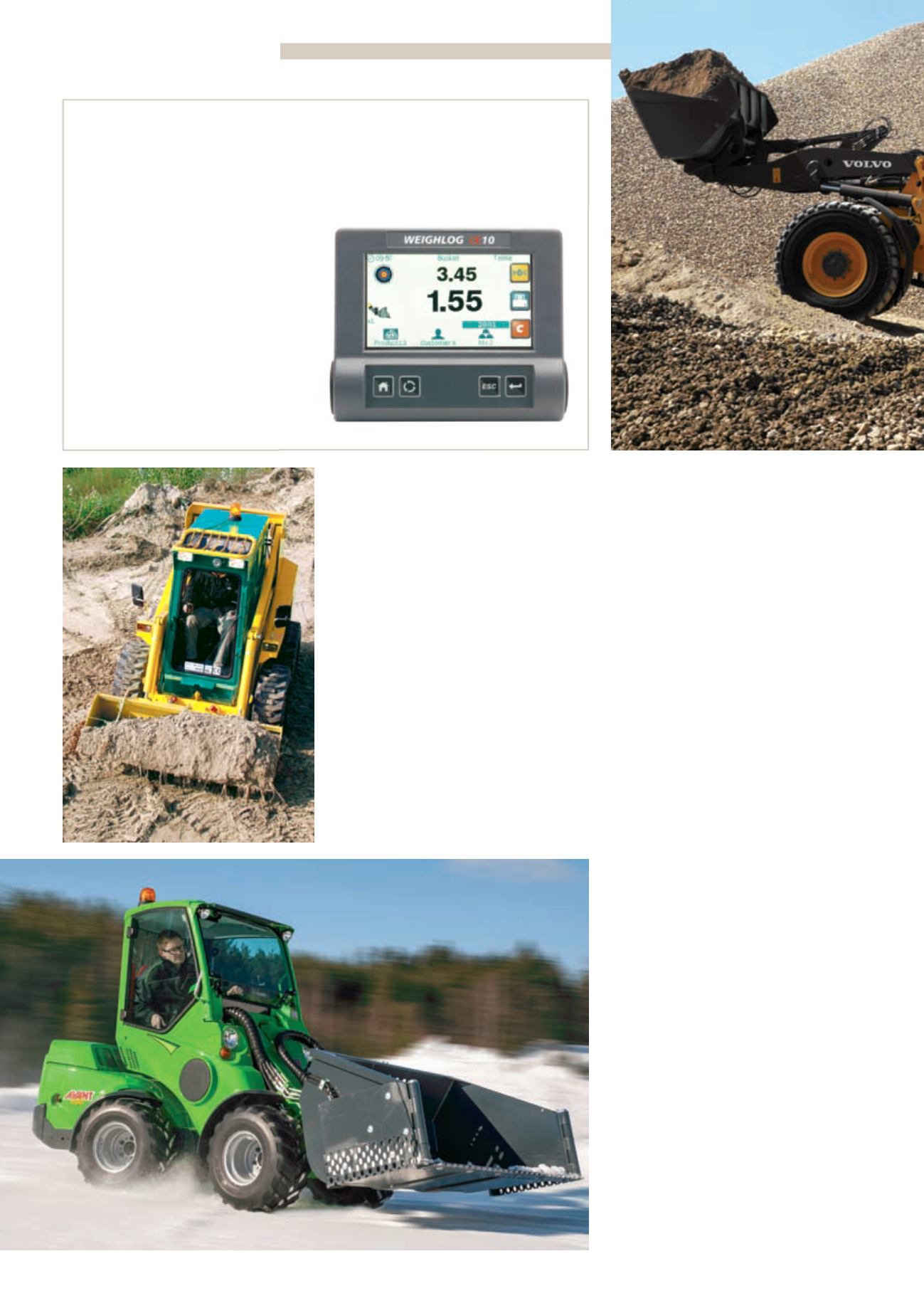

On-board weighing for compacts

RDS Technology has introduced the Weighlog α10 onboard weighing system designed

specifically for compact loaders.

TheWeighlog α10 incorporates a 110mm colour, hi brightness resistive touchscreen display

and additional physical keys providing an

on-board weighing system that can be used

for truck loading or check weighing.

It is said to be suitable for use with up to 10

different attachments – for instance, buckets

or forks – and the system can be retrofitted

onto compact wheeled loaders.

The system measures hydraulic pressure

using up to four sensors at a certain position

on the lifting cycle compensating for

pressure changes in the system.

System can be retrofitted onto compact

wheeled loaders

Yanmar’s skid-steer loaders are

described as very compact

The L50G fromVolvo is in the 9

to10 tonne class of machine

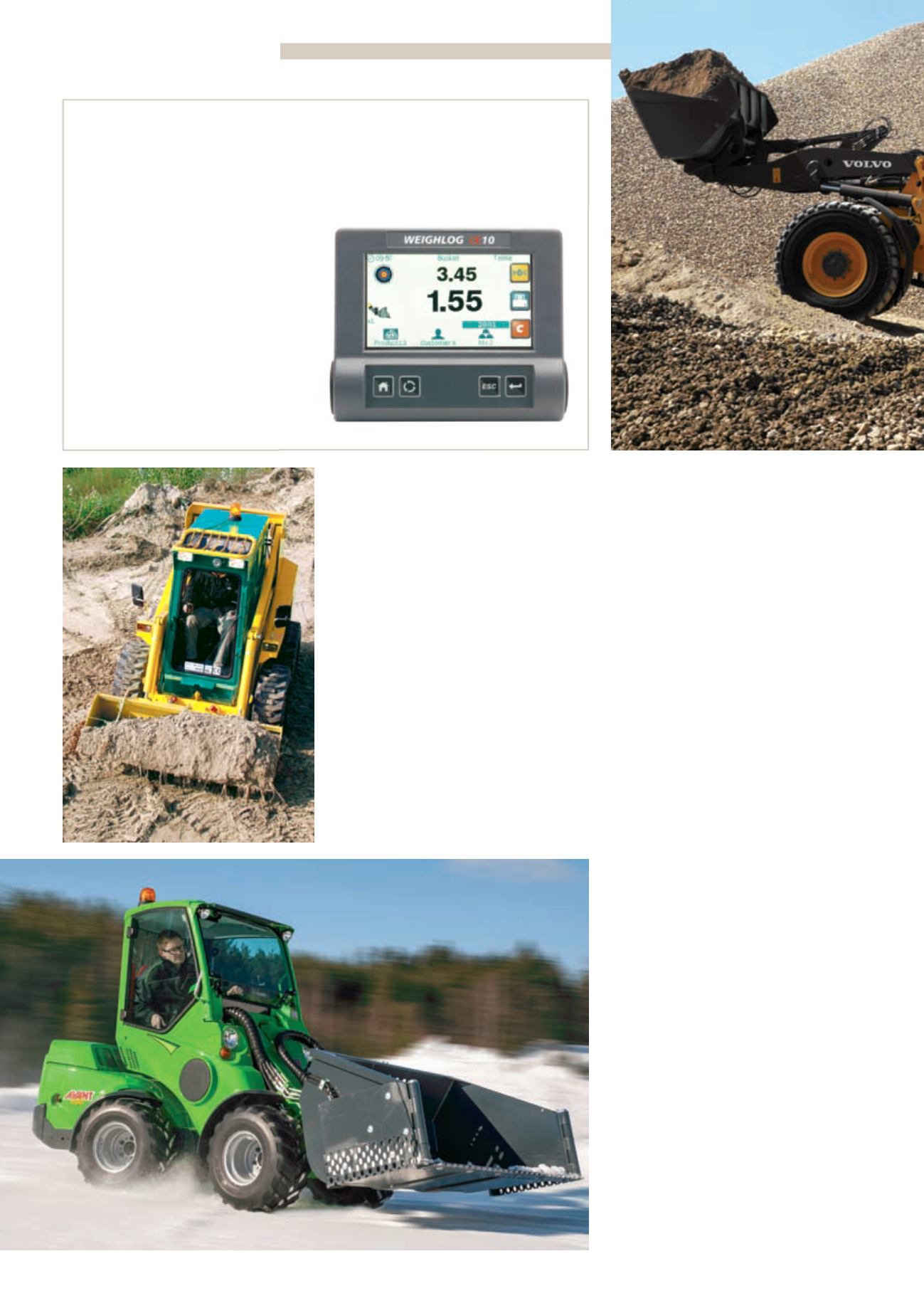

The Avant 640 is said to be small enough

to work in tight working conditions yet

powerful enough to lift over a tonne