34

CONSTRUCTION EUROPE

SEPTEMBER 2013

COMPACT LOADERS

>

In the new cab, there is a new full-colour LCD

monitor, and a menu system that provides a

wide range of real-time information for the

operator.

The cab is also said to benefit from reduced

noise levels and, for the first time on machines

of this size, JCB will offer full climate control

air conditioning as an option.

The 417 will use a 93kW version of JCB’s

Ecomax Stage IIIB engine. This drives through

a ZF four-speed transmission to JCB axles

front and rear.

It has a transmission disconnect feature

incorporated into the service brake pedal,

which JCB said would deliver further fuel-

saving benefits.

It added that the engine offered a fuel

efficiency gain of up to 15% compared to

the previous Dieselmax engine, without any

loss of digging and loading performance.

The 411 is also said to benefit from improved

fuel efficiency with the 68kW version of JCB’s

Ecomax Stage IIIB engine.

The 411 is available with both standard and

super high lift loader configurations, with

the standard arms offering a pin height of

3,487mm and a dump height of 2,624mm

when using a 1.2m

3

bucket.

JCB also has a line-up of 17 new generation

skid steer and compact track loaders. It

claimed the machines were 16% more fuel

efficient than rival models and would save

customers around €2,000 annually.

The new machines include nine large

platform models – the 225, 260, 280, 300 and

330 wheeled skid steers, and the 225T, 260T,

300T and 320T track loaders.

The 260 model and above use a vertical lift

version of the JCB Powerboom single arm,

which is said to provide maximum reach at

full height, while the 225 and 225T feature

radial lift designs and are said to provide

maximum reach at the mid-point of the

lifting path.

The manufacturer's new range also includes

eight small platformmodels. The 175, 190, 205

skid steers and the 190T and 205T compact

track loaders are vertical lift machines. The

135, 155 and 150T models feature a radial

lift design, which is said to offer improved

digging.

JCB said the machines were manoeuvrable

in tight, confined areas, and easily transported

between job sites. However, it claimed the

machines did not sacrifice power, safety,

visibility, comfort or productivity.

The newmachines feature JCB’s PowerBoom

design, which uses a single arm rather than

the conventional two-arm skid steer design.

RUBBER TRACKS

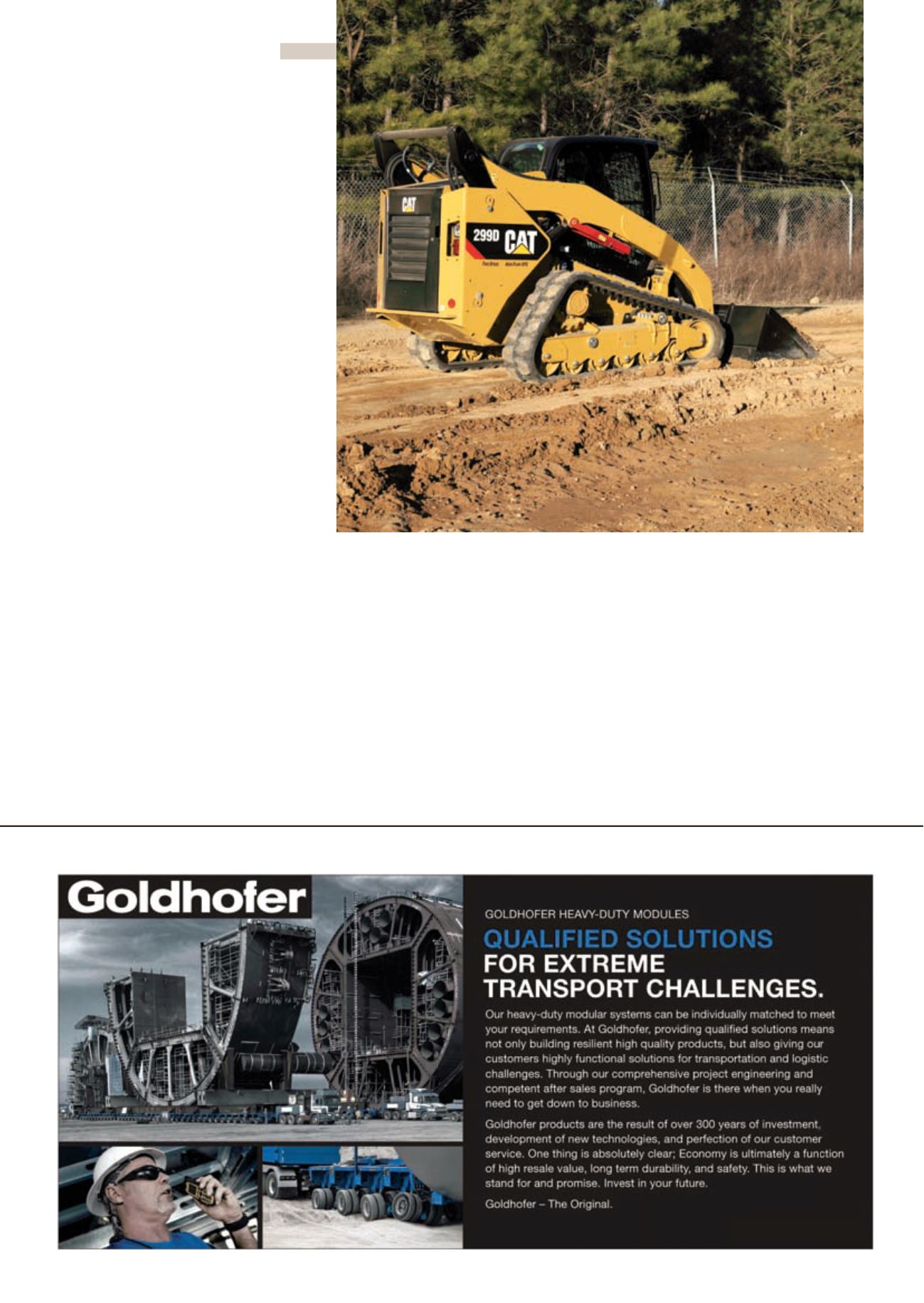

A few years after entering the compact

equipment market with its skid steer loader

in 1999, Caterpillar introduced its first rubber

track loader models.

It claimed that the rubber track multi-

terrain loaders offered best-in-class flotation,

traction and operator comfort in ride. In

2008, Caterpillar added the steel embedded,

rubber track compact track loader with a

steel undercarriage. It claimed that this made

Caterpillar the only manufacturer that could

provide a best-fit traction solution, both in

The Cat 299D has a fully-suspended, steel

embedded rubber track undercarriage