33

CONSTRUCTION EUROPE

SEPTEMBER 2013

COMPACT LOADERS

Like the rest of the new generation machines,

the S450 will come with an enhanced cab

providing superior comfort, visibility and

access to and from the machine.”

He added that a second point of focus was

on the actual performance of the machine,

especially the hydraulics.

“The hydraulic circuit has been redesigned,

involving the reduction of linkages and

introducing straight fittings instead of

adjustable fittings,” said Mr Cuadrado,

“resulting in higher hydraulic power, reduced

maintenance and increased attachment

performance.

“Last but not least, the durability of the

machine has been our third point of focus.

The new generation models come with

auxiliary hydraulics totally protected within

the arms of the machine, as well as a more

robust and protected tailgate.”

The changes that the manufacturers make

can be prompted by a number of elements –

for example, new regulations – but overall, a

machine has to appeal to its customer base.

According to Mr Cuadrado, “The application

in question tends to drive the decision to

purchase one size and type of loader or

another.

“In the case of the compact loader, the

compactness and the versatility provided by

the extensive attachments on offer are the

key decision makers.”

At Gehl/Mustang, Mr Chatillon agreed,

comparing the requirements of a European

customer with a US counterpart. He cited

compactness so that machines could move

easily in European cities, which tend to be

smaller than in the US, with narrow historical

town centres where there is no access for

large loaders.

“Versatility is linked to the wide range

of attachments you can use,” he said, “but

also reliability to do the job by saving time

and by increasing productivity, and easy

maintenance on site by the operators. It’s

reducing the maintenance costs allowing

better productivity.”

He added that more and more, better fuel

efficiency was important because the cost of

fuel was higher in Europe than in the US.

“For instance,” he said, “on the new Gehl

V400/Mustang 4000 V, we introduced a new

cooling fan controlled by hydraulics to reduce

fuel consumption and noise.”

Comfort was important for European

customers, according to Mr Chatillon, who

said some customers were concerned about

vibration noise outside and inside the cabin.

“It means the models dedicated to European

markets offer better comfort to the customer

with less vibration and less inside/outside

cabin noise,” he said, adding that in Europe,

his company sold more closed cabins than in

the US to meet customer needs for comfort.

FUEL EFFICIENCY

One area that JCB is concentrating on with

the launch of two new compact wheeled

loading shovels is fuel efficiency and the JCB

Ecomax engine.

The new models, the 411 and 417, are

powered by the low emission Ecomax

diesel engine, which JCB claimed delivered

improved fuel consumption, reduced noise

and increased productivity.

A larger operator’s cab also features, with

improved ergonomics, a new high lift arm

option on the 417 for increased versatility,

and improved lift capacity.

The 417 – which replaces the previous 416

– and the revised 411 feature JCB’s new

generation appearance, with a new single-

piece bonnet which is said to help with

service access and visibility.

>

is collapsing strongly due to the economic

crisis. This has stopped a large number of

construction programmes where compact

loaders could be used.

“At the same time, Russia is becoming the

biggest market for this range of product

with constant growth over several years,” he

added.

“Let me cut to the chase – Northern

European markets are suffering from the

crisis less than Southern European markets.

This trend should remain the same in 2014.

Growth in Southern Europe will only occur

if Italy and Spain launch new programmes

for construction – individual construction

mainly.”

Regardless of the market situation,

companies have tomove forward, introducing

improved models and working hard on new

technology.

Mr Chatillon said that in Europe, his

company had launched the new Gehl V400

and Mustang 4000V this year. He claimed

these new models, which were launched in

the US and Canada in June 2012, were the

most powerful skid steers on the market.

He said they offered a large range of

applications with dedicated attachments that

required hydraulic power, such as large size

hammers, trenchers and cold planers.

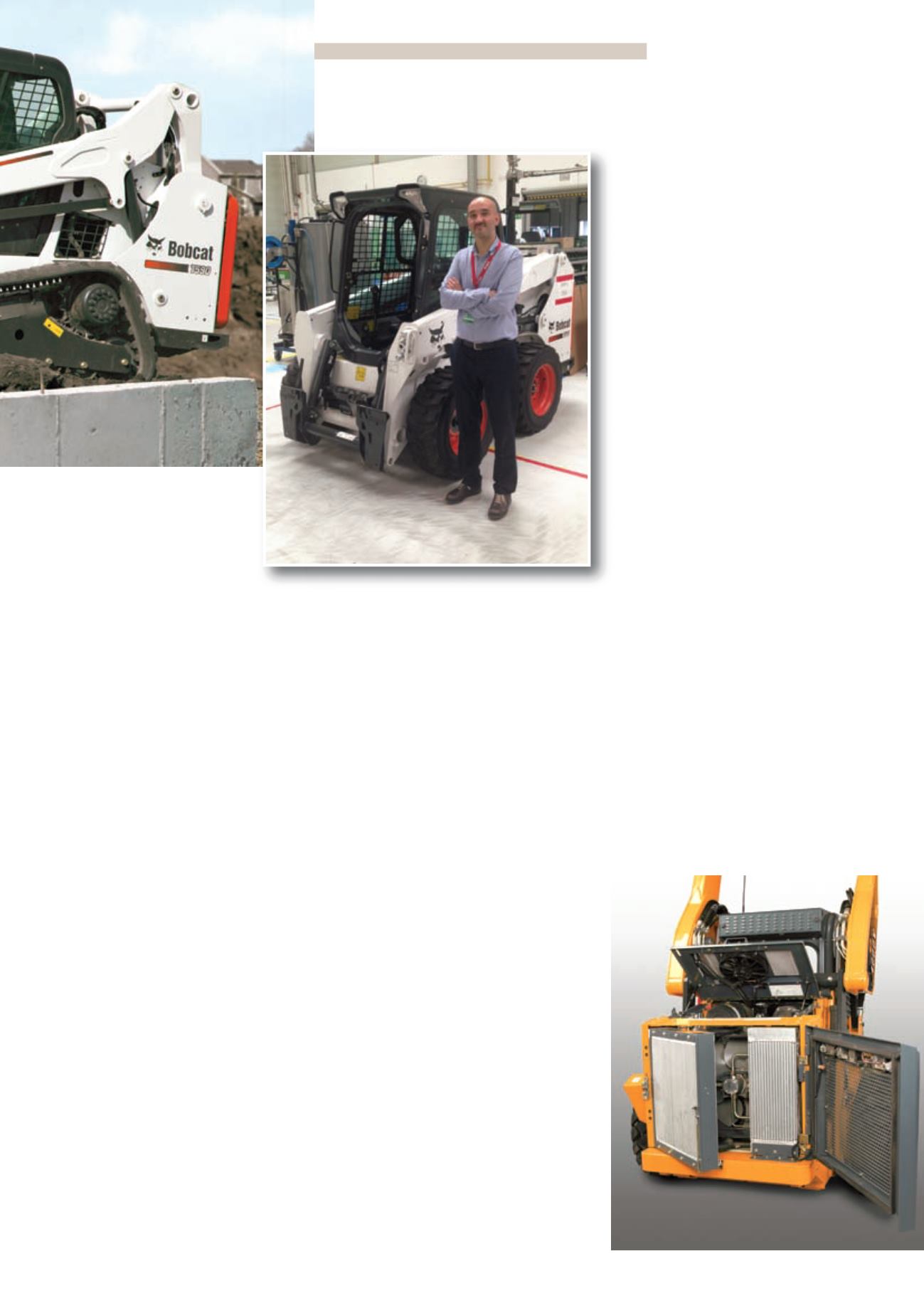

FULL RANGE

Bobcat launched its new generation loaders

in 2010. Mr Cuadrado said, “Following the

launch of the new 500 platform loaders at the

beginning of 2013, we have now successfully

launched all the new Bobcat large- and

medium-sized skid steer, compact tracked

and all-wheel steer loader models.

“In early 2014, we will launch the S450, the

replacement for the S130 skid steer loader.

The Bobcat T590 – one of the new 500

series of platform loaders launched at the

beginning of 2013

Mr Cuadrado, “Conditions are

still challenging”

The Mustang 4000 V has a new cooling

fan controlled by hydraulics to reduce fuel

consumption and noise