international

construction

may 2014

DEMOLTION&RECYCLING

50

Cutting-edge techniques

River restoration

Dams demolished usingmodified breakers

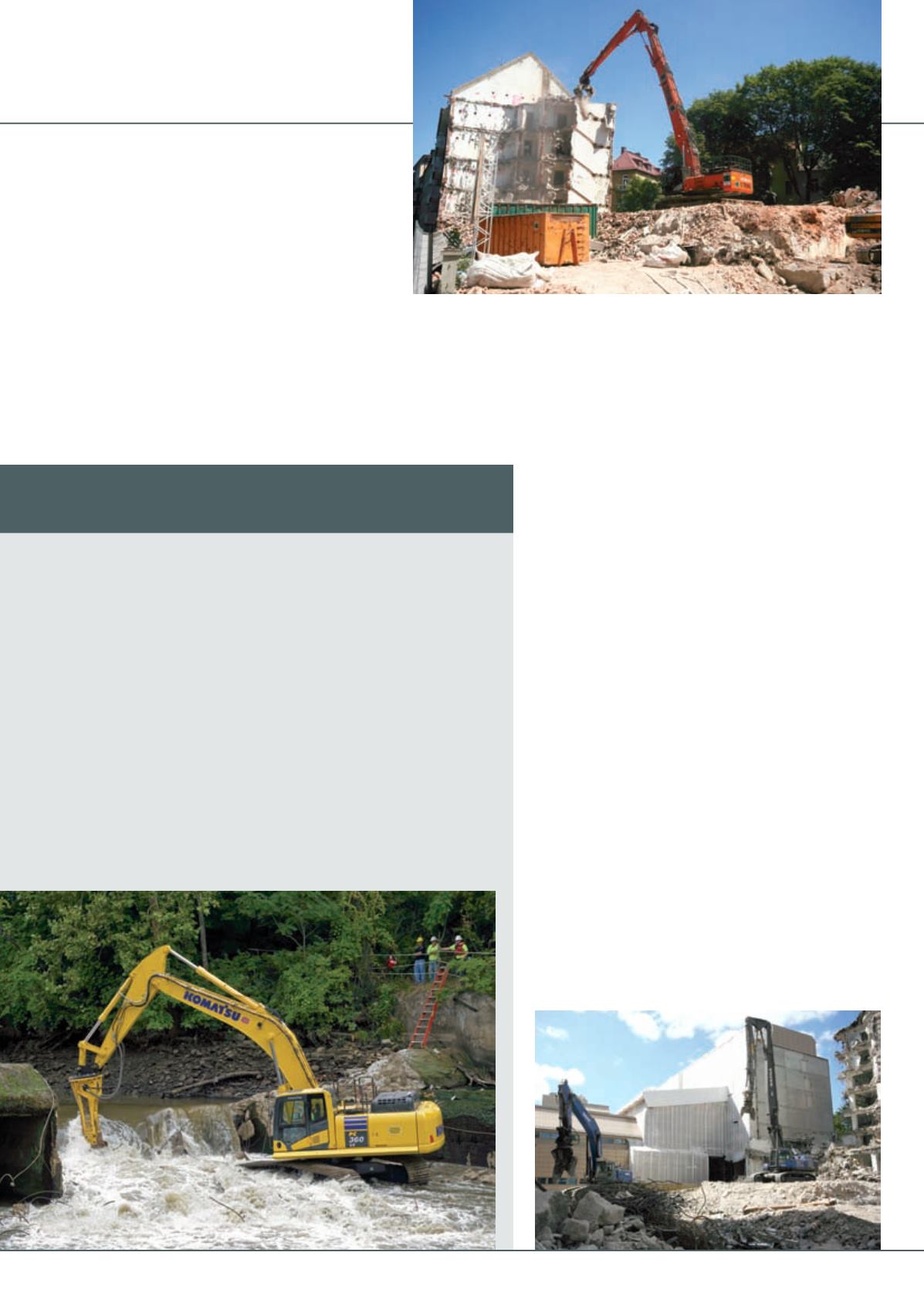

A

s part of the project to restore the once-pollutedCuyahogaRiver inOhio, US, to its

pre-industrial state, River ReachConstructionwas awarded the contract to remove

the SheratonMill Dam and the LeFever Dam that once provided hydroelectric

power. Among the keymachines usedwere Atlas Copco hydraulic breakers equippedwith

underwater kits.

Atlas Copco distributor Columbus Equipment Company suppliedRiver Reachwith a

heavy duty HB 3100 breaker and amuchmore compact SB 552, alongwith an XAS 185

Atlas Copco compressor, whichwas used to pump air into the breakers and prevent water

entering the percussionmechanisms.

The 12mwide, 3m highSheratonMill damwas demolished from an upstream position,

using the SB 552mounted on amini excavator, whichwas positioned on a bargewith the

compressor. The techniquewas then to open up ‘windows’ in the structure to let thewater

through and lower the reservoir behind the dam.

Then a 36 tonne excavator equippedwith theHB 3100moved in from downstream and

it took just a day to remove the rest of the structure. “It was almost too easywith that big

breaker,” said operator ShannonSwaino.

The LeFever Damwas larger at –27.4mwide and nearly 4m high, but the process

proved easier as River Reachwas able to construct downstream access, so no upstream

bargewas needed, and the jobwas completed quickly.

>

The last two years have seen this need for flexibility addressed

even furtherby thedevelopmentofnewconcepts.Thishasreached

the point where a single carrier can be supplied with a range of

front ends allowing it to be used across different applications in

addition todemolition and standarddigwork.

One company at the forefront of this is Kocurek Excavators,

based in Ipswich, UK. In 2013, working together with UK

demolition contractor Armac, which was the driver behind the

project, it developed what is now known as the ABC concept.

This consists of a single carrier than can be equipped with three

different front ends thatprovidevariableworkingheights and tool

sizes in addition to a standarddigboom.This allows themachine

to be tailored to the application, but more importantly, only the

single carrier is required for fourpotential applications if all boom

configurations are available.

And the flexibility concept is being taken amassive step further

by Kocurekworking in partnershipwithGermanHitachi dealer

Kiesel.The result is a single carrier, in the first instance aHitachi

ZX470LC, which is able to carry an evenwider range of booms

for a varietyof different applications forGerman customerAWR.

It is thefirst inwhatwill beknown as theKMC470-BTV range.

KMC is theacronym forKieselMultiCarrier,with theB standing

for the OilQuick boom connect system, T for the Tritech three

cylinderquattrovalve lift systemandV for variableundercarriage.

The idea is that every470producedwill have the same stubboom

with the OilQuick and three lift cylinders. The three cylinders

provide the necessary power when in demolitionmode with the

valve providingmore normal flows for when themachine is in a

standard excavation configuration.

Range of booms

Kiesel and Kocurek are developing a range of booms for the

carrier, offeringvertical reaches from18m to34m fordemolition

work, as well as materials handling equipment and the standard

excavator boom.

The concept is also being applied toHitachi’s ZX350machine

to turn it into theKMC350-BTV.The various boomoptionswill

allow this to work as a standard excavator, materials handler or

demolition excavatorwith a range of reaches up to24m.

The fact that companies like Kiesel and Kocurek are at the

cuttingedgeofhigh-reachdemolitionexcavatordesignunderlines

the fact that this is an area where European companies tend to

lead theway.However, that is not to say that high reachmachines

are only used inEurope. Far from it.

Visitors to this year’s ConExpo-Con/Agg exhibition in Las

Vegas, US can’t have failed to notice the high-reachmachine on

Kobelco’s stand.The 112 tonne SK1000DLCoffers amaximum

reachof 38m.

The Japanese manufacturer said that it would be bringing 19

variants of its demolition machines into the US, along with 12

scrap handlers, over the next fewmonths. Interestingly, Kobelco

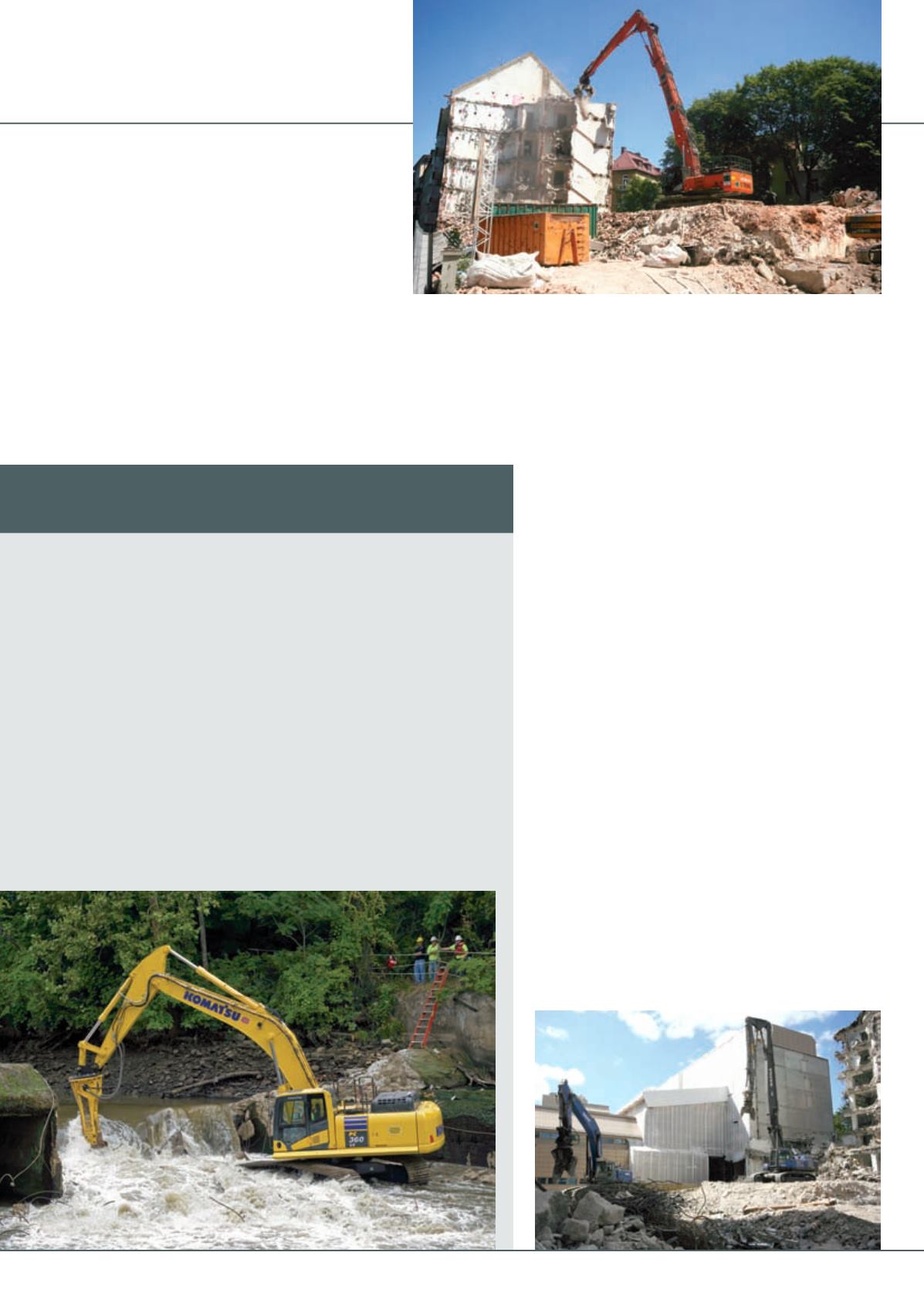

Hitachi’s 25m ZX470LCH is one of only three high reach excavators currently

available that complieswith the latest engine emission regulations.

Volvo launched Stage IIIB versions of its 27.4m EC480DHR

and 21m EC380DHR at the Bauma exhibition in April 2013.

Here the first EC470DHR is at work in Helsinki, Finland.