international

construction

may 2014

DEMOLTION&RECYCLING

54

Cutting-edge techniques

T

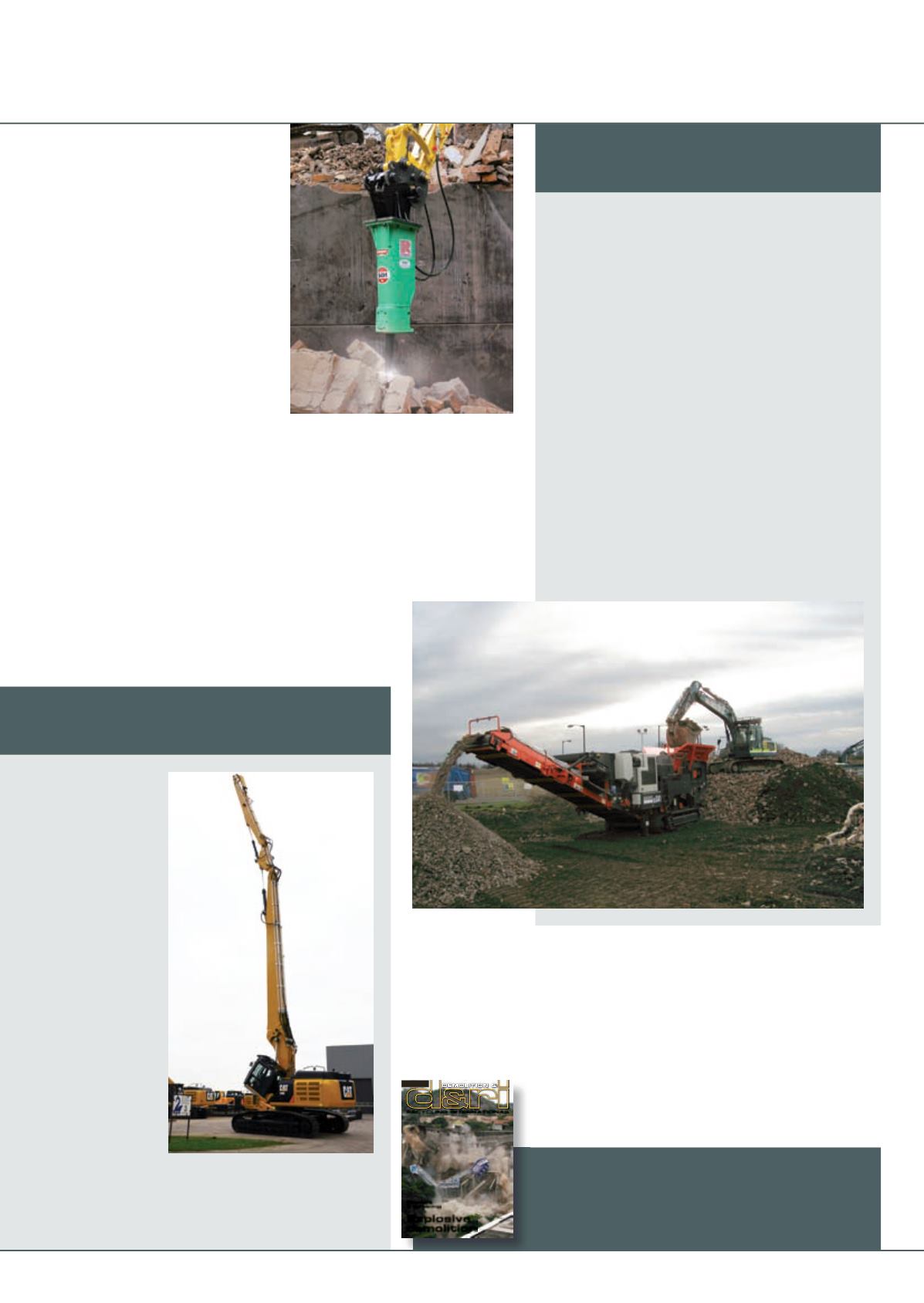

he latest addition toDurham, UK-basedMGLDemolition’s

fleet is aQJ341 tracked jaw crusher from Sandvik

construction.

Managing director, MarkDavison said, “One of the

distinct advantages of theQJ341 is that due to its inherent

transportability from site to site, andmanoeuvrability around

the site, it is literally able to go direct to thematerial, and

reduce it for reuse on-site. This not only providesmaterial for

use straight away, but reduces haulage costs, aswell as being

environmentally sustainable.”

The company’s newQJ341 is currently being used to crush

-75mm demolitionmaterial on a variety of projects. Key

features include its 1200 x 750mm feed opening, hydraulically

adjustable closed side setting, high reduction ratios and a

reverse crushing action to relieve blockages, plus an automatic

central lubrication system.

MGLDemolition’s QJ341 also features a load control system

for the feeder drive, level sensor fitted to the jaw, and speed

wheel fitted to themain conveyor. One of the key design

changes now sees themain conveyor being fittedwith a raise

and lower facility for increasedmagnet clearance together with

ease of transportation.

Giant cats

German sales successes for 29mmachines

Crusher addition

UK contractor adds new tracked jaw

G

erman

Cat dealer

Zeppelin

has reportedly

sold four 349E

UHD high reaches

to demolition

contractors around

Germany. The

machines have

pin heights of 29

m, can carry a 3

tonne tool at that

height and feature

hydraulic extending

undercarriages.

There is a

hydraulic boom

coupling system and

all the all hydraulic

hoses have quick

couplings, allowing

boom changes to

bemade in just 10minutes. Dutchmodifier STC conducted the

engineering design of the boom and hydraulic systems, with all

fabricationwork and hydraulic system production carried out at

its facility inCoevorden, theNetherlands.

DEMOLITION &

RECYCLING INTERNATIONAL

AKHLGroup publication

Explosive

demolition

VOLUME 16

NUMBER 2

MARCH-APRIL2014

Crushing

& screening

after the implosion for ease of sorting and

recycling. Following the soft strip, screens

were positioned around the outside of

everyfloor thatwouldhave charges placed

in them to guard against flying debris.

The implosion sequence of the

supporting columns was designed based

on a simulation by Applied Science

International (ASI). The concept was to

keep the implosion in the centre of the

buildings, rather than towards the edges,

to cause them to fall inwards and away

from surrounding obstructions.

Other measures were taken, such as the

use of steel cables in the second building

to ensure that the structure’s water tank

did not fall towards an adjacent flower

shop.

When it came to the implosion, delays

of 300 milliseconds were set up between

the blasts on each set of columns, starting

at the centre of the building, with the

perimeter columns the last to go. In fact, some of the perimeter

columns were not blasted to help ensure all the debris remained

on the existing buildings’ footprint.

Thecharge ratioof the implosionwas0.300kgperm

3

of column

volume. This ratio prevented any fragments from penetrating

the screens and hitting other buildings in the vicinity. A total of

130kgof explosiveswas used, spreadover 1,200manuallydrilled

holes.

The implosion was carried out at 8:00 am on November 2,

2012. No power cables were damaged during the event, and in

additionno cracks in anyof the adjacent buildingswereobserved,

while all the debris from the implosion was contained inside

the building footprint, as predicted by the engineers behind the

project.The peak particle velocity recorded by seismographs was

below 3mm/s, whichwas safely below themaximum limit of 15

mm/s allowedunder Brazilian standards.

This all illustrates how sophisticated the demolition industry is,

be it through scientifically engineered explosive demolition, or

the latest inflexible demolitionmachines.

iC

Demolition&Recycling International

is amagazine for

the global demolition industry. Formore information,

including how to arrange a FREE subscription, please visit

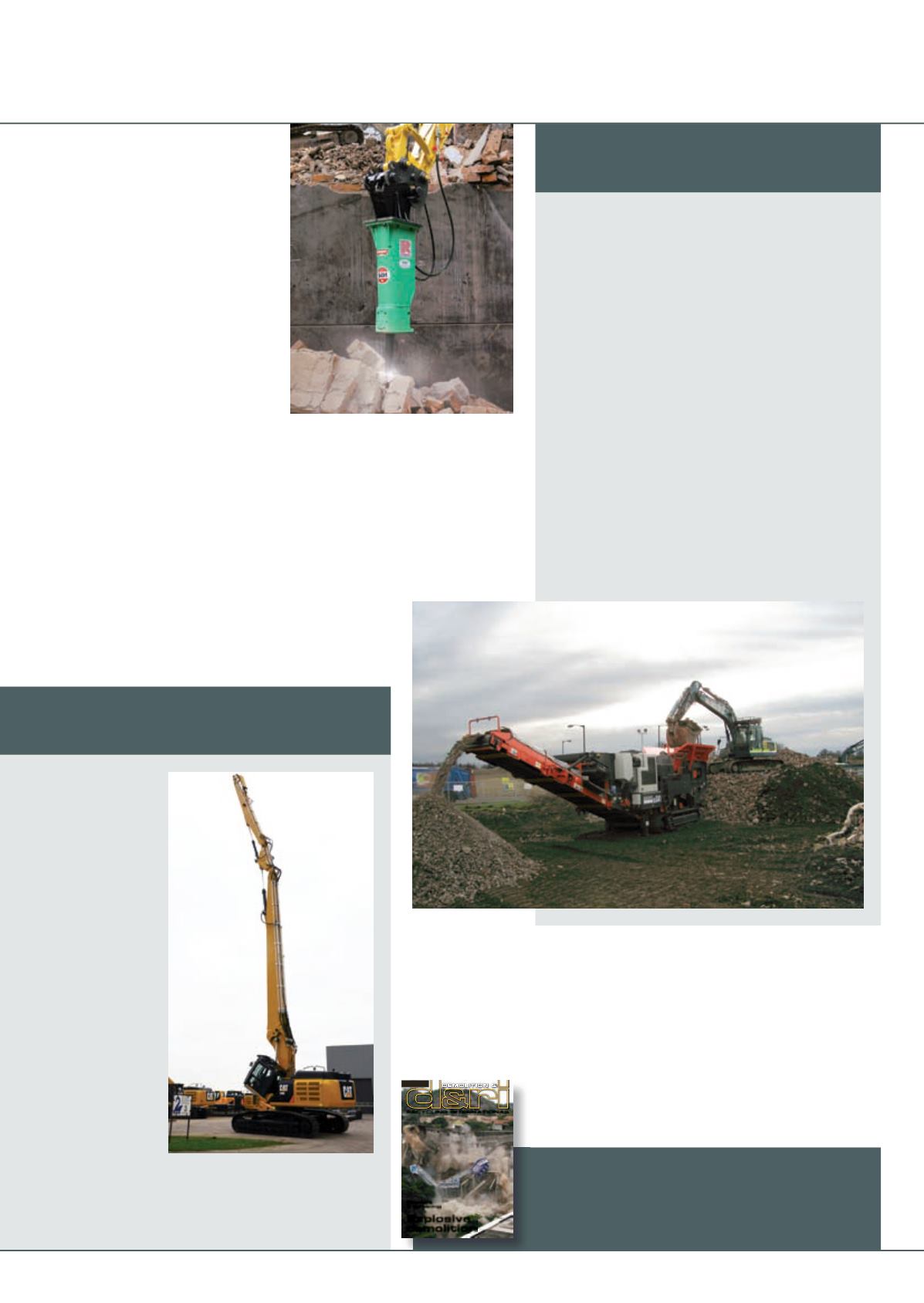

One of Montabert’s latest additions is

the 501 NG, a name that references a

famous product for the company, the

BRH 501 breaker launched in 1969. The

newmodel features an energy recovery

system and blank-fire protection.