international

construction

may 2014

42

Intelligent tools

UTILITES

various spraymethods. Somuch so that even the leading spray

companies are now starting their own departments that only

workwith lining.”

He said housing associations, property owners, property

managers and construction companies were coming to

understand the benefits of renovating sewer systems without

open cut construction.

“When the methods and materials are reliable and the end

result is the same as a traditional pipe replacement, we see that

>

evenmore people choose lining instead of breaking up property

to replace old leaky pipes.”

Trenching

However, those on the trenching side of the underground

utilitiesmarket would likely argue that theirmethod is themost

popular. In any case, if the job requires the ground tobe opened

up, it presents contractors with an entirely different array of

challenges.

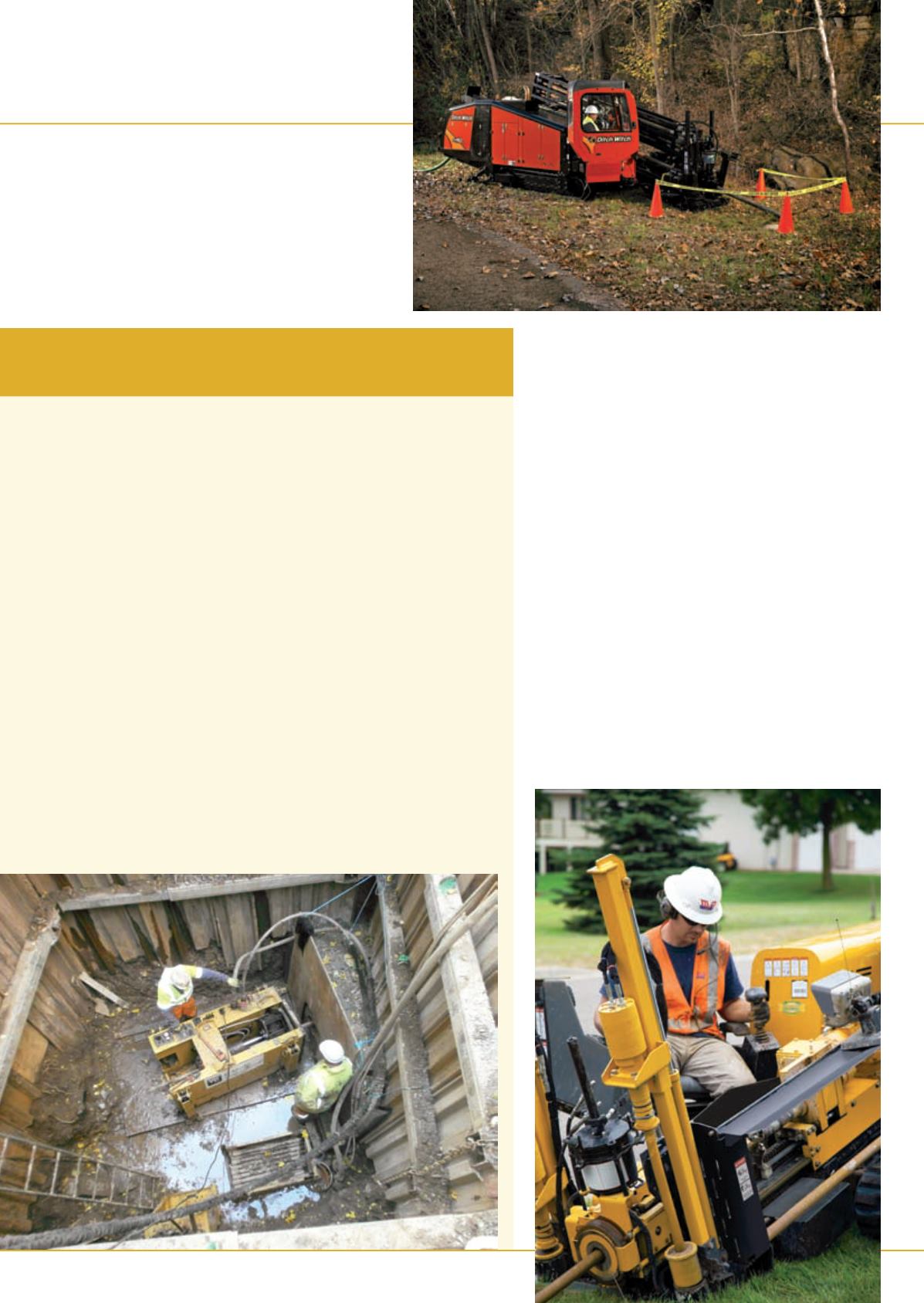

Indeed, National Trench Safety said trench shields were

evolving as contractors moved more and more towards using

lightweight excavationmachinery to dig trenches.

Joe Turner, director of engineering, said, “The change in

excavation technology is strongly related to the advancement

of smaller, lightweight equipment for excavations inmid depth

utilitywork.

“Large, heavydown anddeep excavators tear up streets, require

S

cottishWater required the replacement of a60m length of 300mmdiameter sewer

witha600mmdiameter pipe inEdinburgh, UK– a job that presenteda challenge to

contractor PipelineDrillers.

Various optionswere considered, including open cut, horizontal directional drilling (HDD),

standardpipebursting andauger boring. But all were rejecteddue to a range of factors

including the limited siteaccess and the risk of local disruptionandenvironmental damage.

A combined auger boring rig andpipeburst rigassemblywas selected for the task– at one

side of the run,where the existingpipe ranat 3.5mdeep, aPerforator PBA150 auger boring

systemwith150 tonnes of thrustwas used. At the reception end of the run, aHammerhead

100 tonne capacityHB100pipebursting rigwas positioned, providedbyUMole.

A series of pulling rodswerepassed through theexistingpipe to connect themachines.

Working together toprovideup to250 tonnes of forceat thepipe eatinghead, thePerforator

unit jacked the assembly head forwardwhileat the same time theburster rigpulled the

assembly towards its operatingpit.

Not only did this provide sufficient thrust to theburstinghead to fracture the oldpipe, but

also enoughpressure toensure thenewpipepassed into thegroundeffectively. At the same

time, thedisplacedearthand fragments of thebrokenpipewere transferredbackdown a steel

sleeveby the auger spiral, and removed to the surfaceby skips from the jackingpit.

A600mmdiameter sewer pipewas inserted through the sleevepipe and connectedat

either end to the remainder of the sewer network. Theduration of theworks totalled two

weeks.

Peter Taylor,managingdirector of PipelineDrillers, said, “Thiswas not an easy project by

anymeans. The logistics bordered onnightmarishwith limits on equipment size, site storage,

transportation andprecise timing. However, our crewworked extremelywell with [lead

contractor] George Leslie’sworkforce to safely andefficiently completewhatwas something of

auniqueproject under challenging circumstances in an excellent timeframe.”

Lateral thinking

A pipe bursting system came into its own on a sewer project

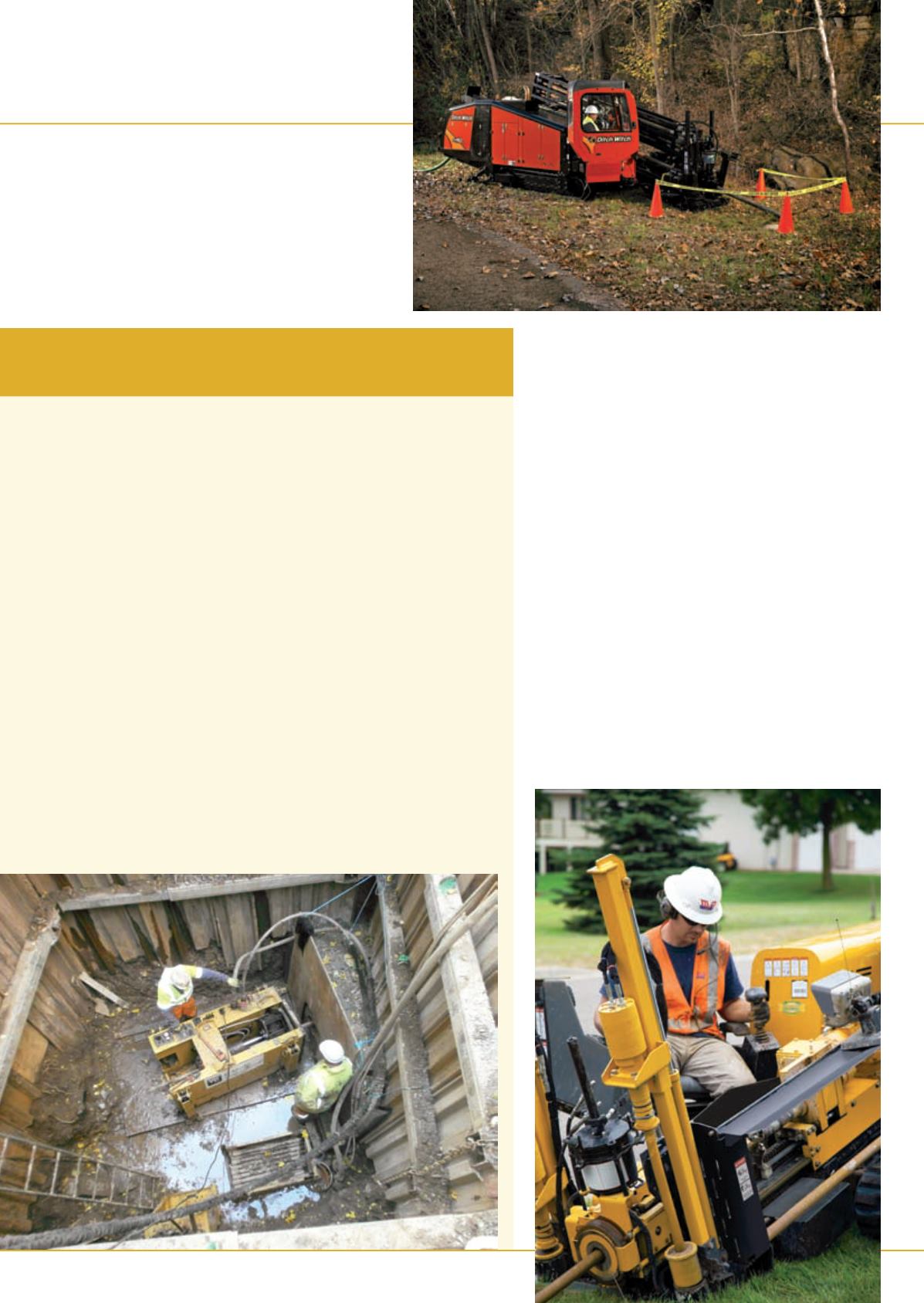

DitchWitch’s new JT60 and JT60 all-terrain HDD rigs come

factory-equippedwith GPS technology for fleet tracking and

remote viewing of machine data.

Vermeer’s new Tier 4 Final-compliant D9x13 S3 Navigator

HDD rig is the first of the S3 generation of drills, and

has been designed for installation of utilities such as

communication, power, gas andwater, aswell as some

limited sewer applications.