international

construction

may 2014

CONCRETE

36

Early involvement

made and we got a very positive and professional response.

Within a short time we had the drawings and they said ‘we

can do it.’We took a trip toNorthCarolina and purchased the

machines,” he said.

The wall was built using a three-pass operation – first, the

3.8 m base was poured with a 5700-C-MAX using a custom

pavingmold.Then, each 2.1m side wall was poured over steel

reinforcements to complete the canal.

The two 5700-C-MAX slipformers were fitted with custom-

engineered straddle legs to allow them to fit inside the canal to

pour the side walls, while a custom-designed belt conveyor was

alsoneeded to feed the concrete to the hopper on top of the tall

barriermould.

The contractor’s record for a single day’s pours were 274 m

on thewall and 251m on the base. In total, over 15,600m3 of

concretewas used.

However, it is one thing putting concrete in place, but quite

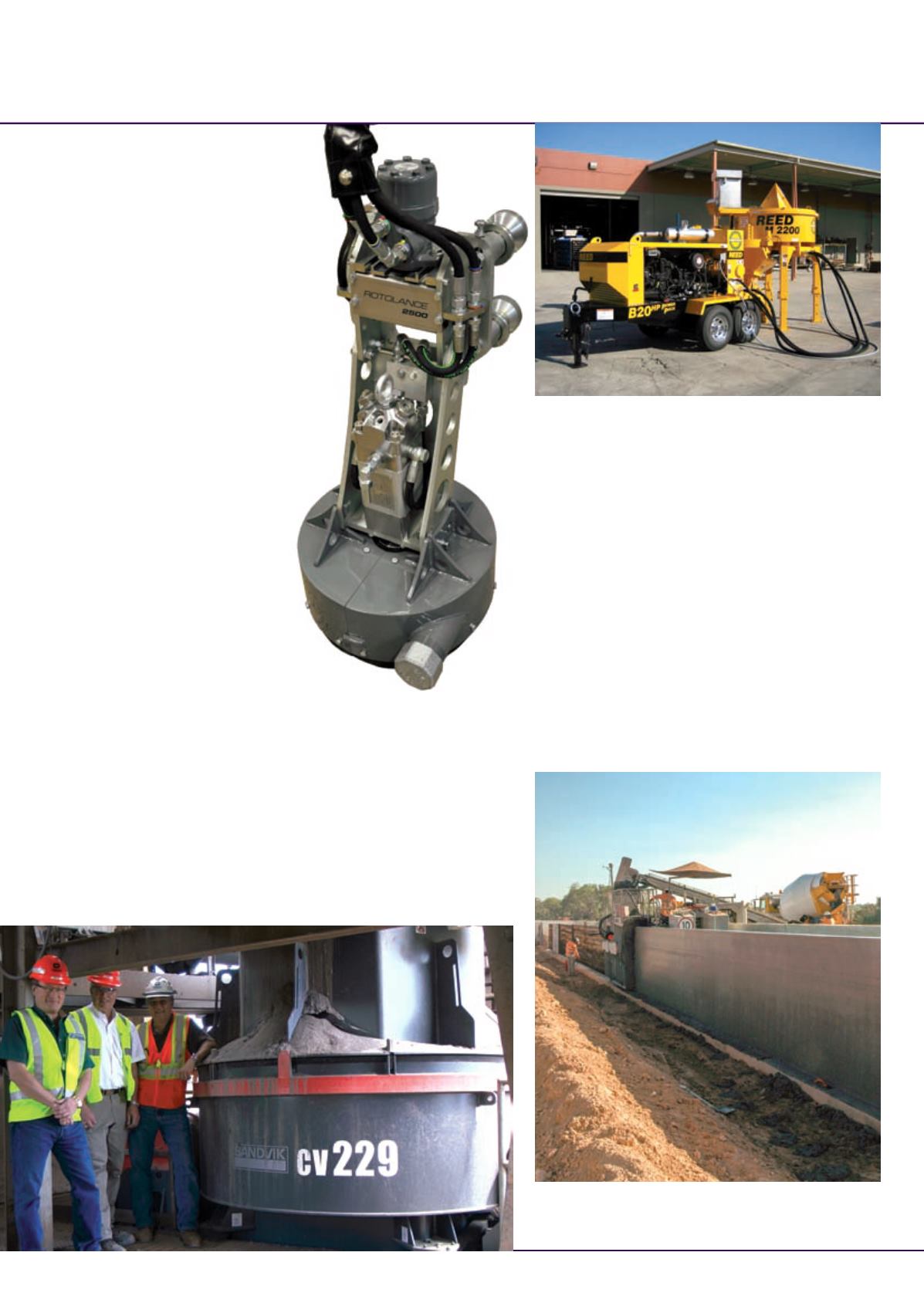

Reed’s towableMixerPump Combo pump has been designed

specifically for shocrete contractors needing a powerful, high

pressure shotcrete pump and a fast, robust mixer.

Two 5700-C-MAX slipformers from Power Curberswere used

to construct 2.1m sidewalls for a stormwater canal project

in Australia.

completely mix 998 kg of refractory material in 3

minutes.

On the higher end of the scale in terms of mixing

capacity, Liebherr has installed a Betomat V 1010

mixing tower for Alfons Greten inEssen, Germany

– the largest of its mixing plants, and one that had

only been installed once previously.

The set up for Alfons Greten consisted of a

1,000 m³ capacity plant and five silos capable of

storing454 tonnes of cement.The contractorwill use

it for producing prefabricated reinforced concrete

elements.

The plant can be customised with two Eirich

mixer systems upon request, and features a

Liebherr Litronic-MPS III mixing plant

control. Additionally, exhaust air filter

systems are in place to reduce dust

emissions, and the plant is also equipped

with heating and insulation to allow

smooth operating duringwintermonths.

Breaking themould

It is often down to manufacturers to

demonstrate the full capabilities of their

machines, and to point out that they can be used

for more than just run-of-the-mill jobs. For instance,

when Australian firm Baldwin Civil NT was approached

about constructing a stormwater canal as part of the new Inpex

natural gas project in theNorthernTerritory, it didn’t know if it

was possible to slipform a 2.1m highwall, according to Power

Curbers.

It had been assumed that the only options for a wall that size

were form-and-pour or pre-cast, according to Baldwin Civil

founder David Baldwin. “Power Curbers was the first call we

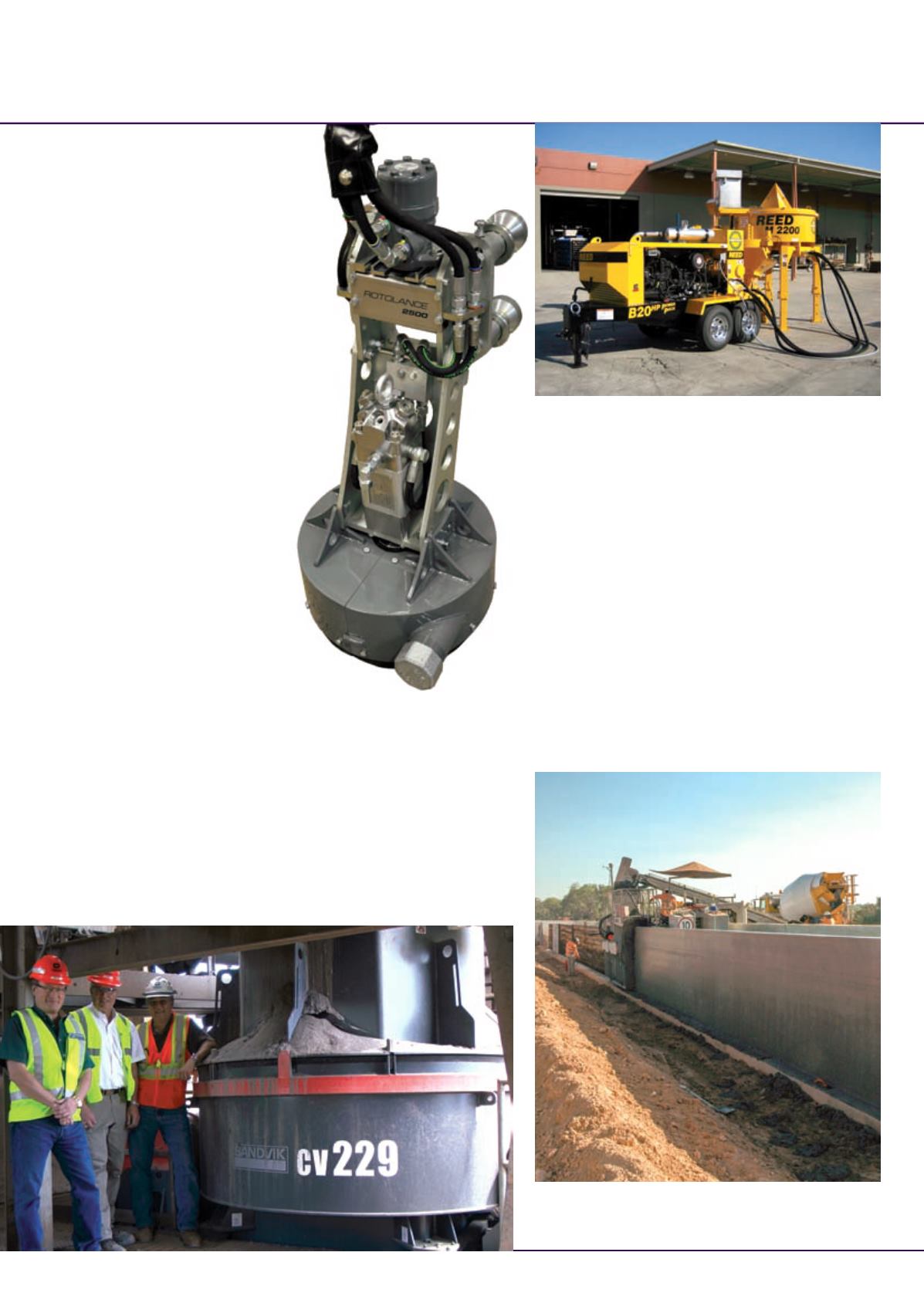

Designed for shallow concrete

removal, the Rotolance 2500 uses

ultra-high pressurewater jets to

remove layers of concrete.

A VSI crusher from Sandvik Construction has helped Hawaii-based producer

Hawaiian Cement, supply aggregates for the island’s construction industry. Before

adopting the CV229 from Sandvik, the company had to import sand fromBritish

Columbia, over 3,200 km away.