31

may 2014

international

construction

CONCRETE

Early involvement

>

A

s pressuremounts on contractors towork efficiently and

cost-effectively, concrete equipment manufacturers and

other suppliers are upping their game tohelpmeet these

demands.

This can start at the design stage and could include anything

from models of the exact amounts of concrete that will be

needed andwhere, to co-ordinating just-in-time jobsite delivery

of equipment, and automatic calculations of concrete setting

times.

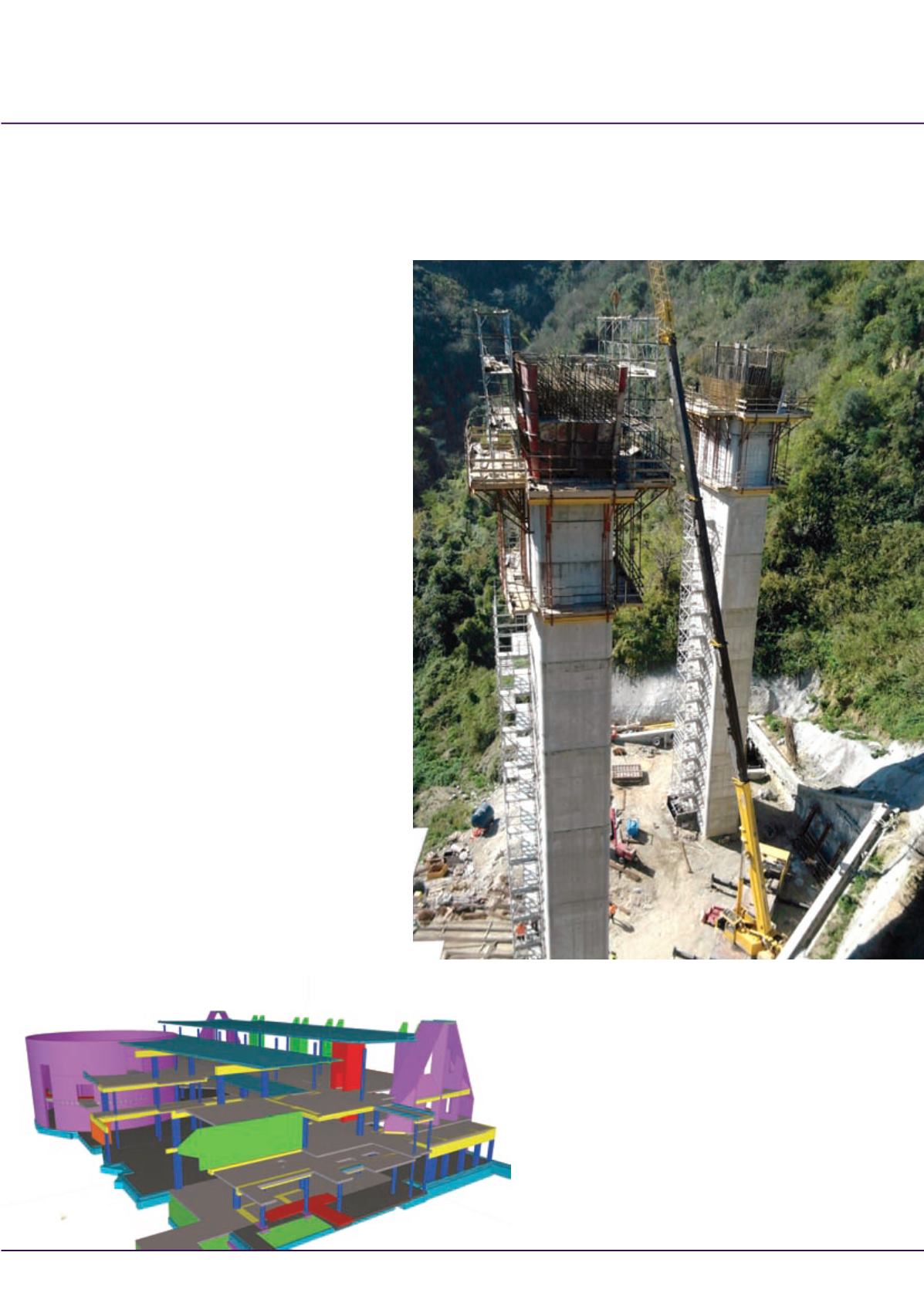

US-based concrete contractor Adjustable Forms, for instance,

tackles large-scale cast in-situ concreteprojects using technology

such as 3D modelling and building information modelling

(BIM). The company uses Tekla Structures Design BIM

software to help streamline many of its business operations,

frompreparingbids, todesign and co-ordinatingworkflowonce

the project starts.

Working from 2D CAD drawings, a PDF or a 3D model

supplied by the design engineer, the company creates a

preconstruction 3D model in the BIM software and extracts

material quantity information. Adjustable Forms project

managerEricLindquist said the technologyhelped the company

to producemore accurate bids.

“We do all of our quantity takeoff/extraction from the

preconstructionmodel to ensure the scope is correct,” he said.

“We extract the quantities and import them into an estimating

tool, which allows us to develop accurate estimates for bidding

jobs, minimising the risk of blowing an estimate based on

miscalculated quantities.

The company also used a preconstructionmodel for drawing

co-ordination. This helps them identify issues with the design

and bring it to the attention of the owner, general contractor

and design team.

Concrete equipmentmanufacturers

are increasingly getting involved in the

planning stages of projects to ensure jobs

run smoothly.

HelenWright

reports.

Early involvement

US-based concrete contractor Adjustable Forms tackles

large-scale cast in-situ concrete projects BIM technology

from Tekla.

During construction, the technology canbe used to establish a

workflow for different processes – from drawing co-ordination,

schedule loading, pour management, rebar detailing, shoring

and formwork layouts, as well asmodelling safety systems.

3Dmodelling

Meanwhile, 3Dmodellingwas central toNorwegian contractor

Hæhre’s design for the twin-deck Labbdalen Bridge. This will

be a key new structure in the country’s 3,140 km E6Highway

improvement programme – the main north-south road linking

Norway to Sweden.

Falsework & formwork specialist RMD Kwikform worked

together with Hæhre’s to supply formwork and shoring to

support construction of the 73 m East Labbdalen Bridge and

78mWest LabbdalenBridge.

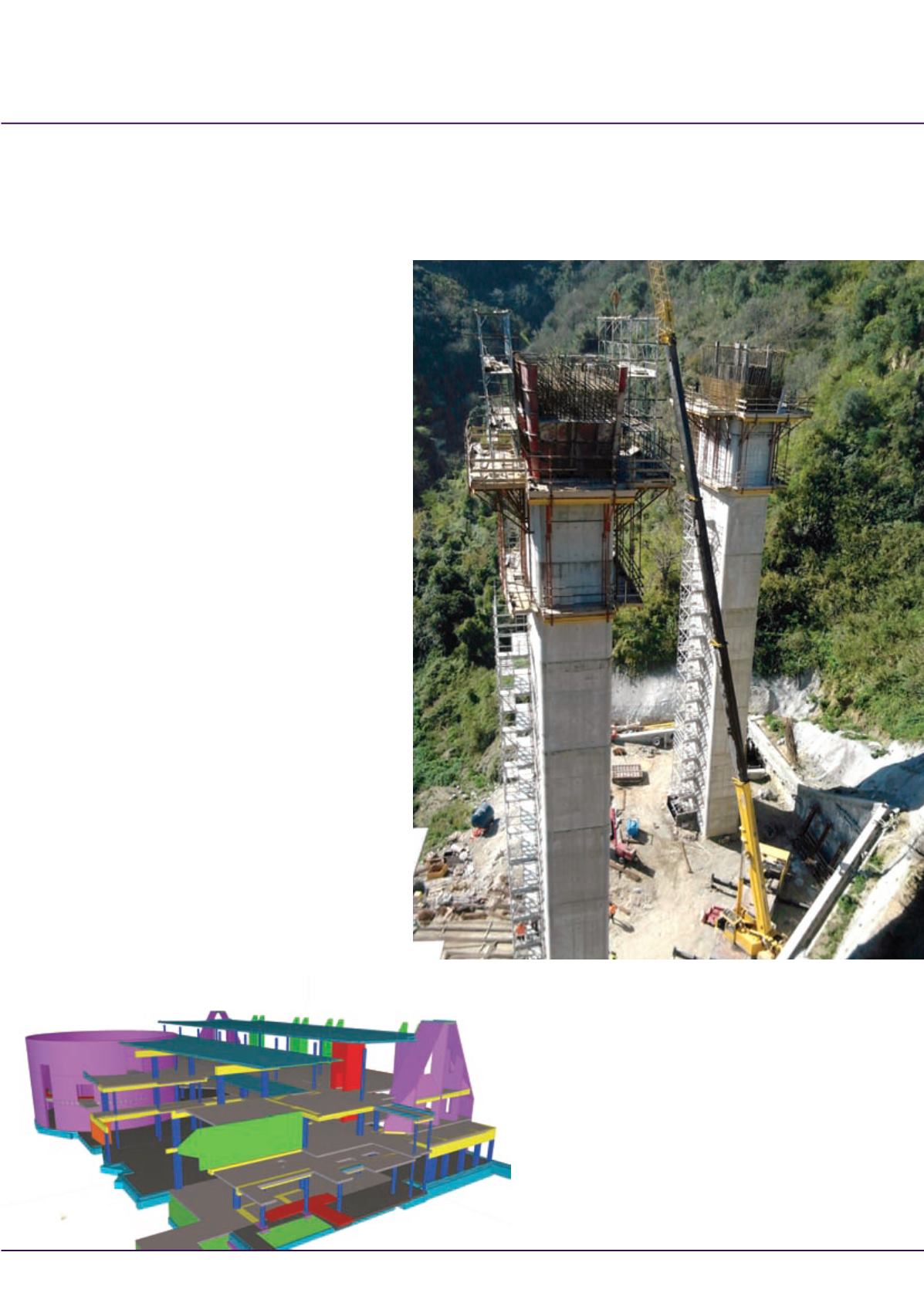

Pilosio said

70% of the

formwork

it supplied

to support

construction

of amotorway

junction north

Durban, South

Africa, was

tailor-made

for the job.