LIFTING&RIGGING

SITEREPORT

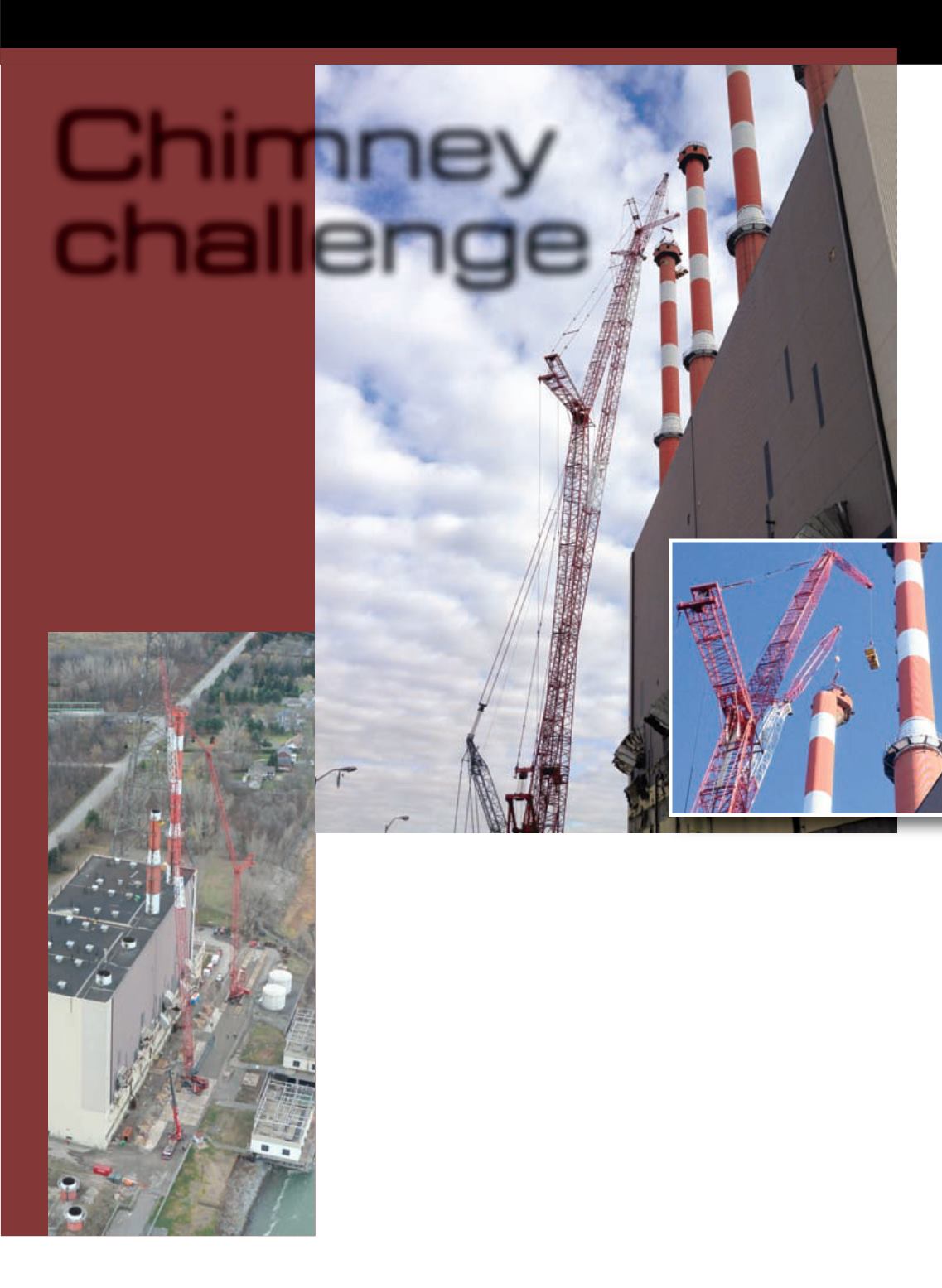

Dismantling four 465-foot

tall chimneys required

skilled crane operation by a

Guay Inc. team.

L

ate in2013, Sorel-Tracy,Quebec

province,Canada-basedGuay

Inc.was calledon todevelop an

engineering and liftingplan andprovide

the cranes todismantle four chimneys

that stood about 465 feet tall. The cranes

wouldneed to lift 75,000pounds at a105-

foot radius andwouldneed tobe able to

movequicklybetween each chimneywith

theboom fully erected.

“The challengewas to coordinate the

workbetween the cranes on site,” said

GuayVicePresidentGuillaumeGagnon.

At the jobsite,Guayprovided a700-ton

capacityTerexCC2800-1 riggedwith

452 feet ofmainboom, 78 feet of jib and

Superlift tohold the chimneypieces. The

cranewas equippedwith180metric tons

of counterweight and60metric tons of

carbody counterweight. Each chimney

was cut intoninepieces.

45

The second craneon the jobwas a

ManitowocM2250 riggedwith200 feet

ofmainboom, 200 feet of luffing jib and

120 feet of jib. This cranewas equipped

with95metric tons of counterweight and

27metric tons of carbody counterweight.

The cranewas riggedwith amanbasket

fromwhich aworker cut the steel on the

chimney.

“Weneeded toplanourwork reallywell

andassureprecisecraneoperationbecause

each crane’s boomwere sometimes really

close to eachother,” saidGagnon.

As each sectionwas cut and ready to

comedown, a three spreader-bar system

wasused to lift eachpiece.

A third craneonsitewas a250-ton

capacityGroveGMK6250L thatwasused

as an assist crane tohelpwith rigging the

othermachines and to tail the chimney

pieces at ground level.

■

MAY 2014

ACT

Chimney

challenge

After the craneswere

set up and rigged, the

sky highwork began

with aworker in aman

basket hanging from

theManitowocM2250

cutting the steel sections

of the chimney and then

the operator of the Terex

CC2800-1 bringing the

chimney section down.

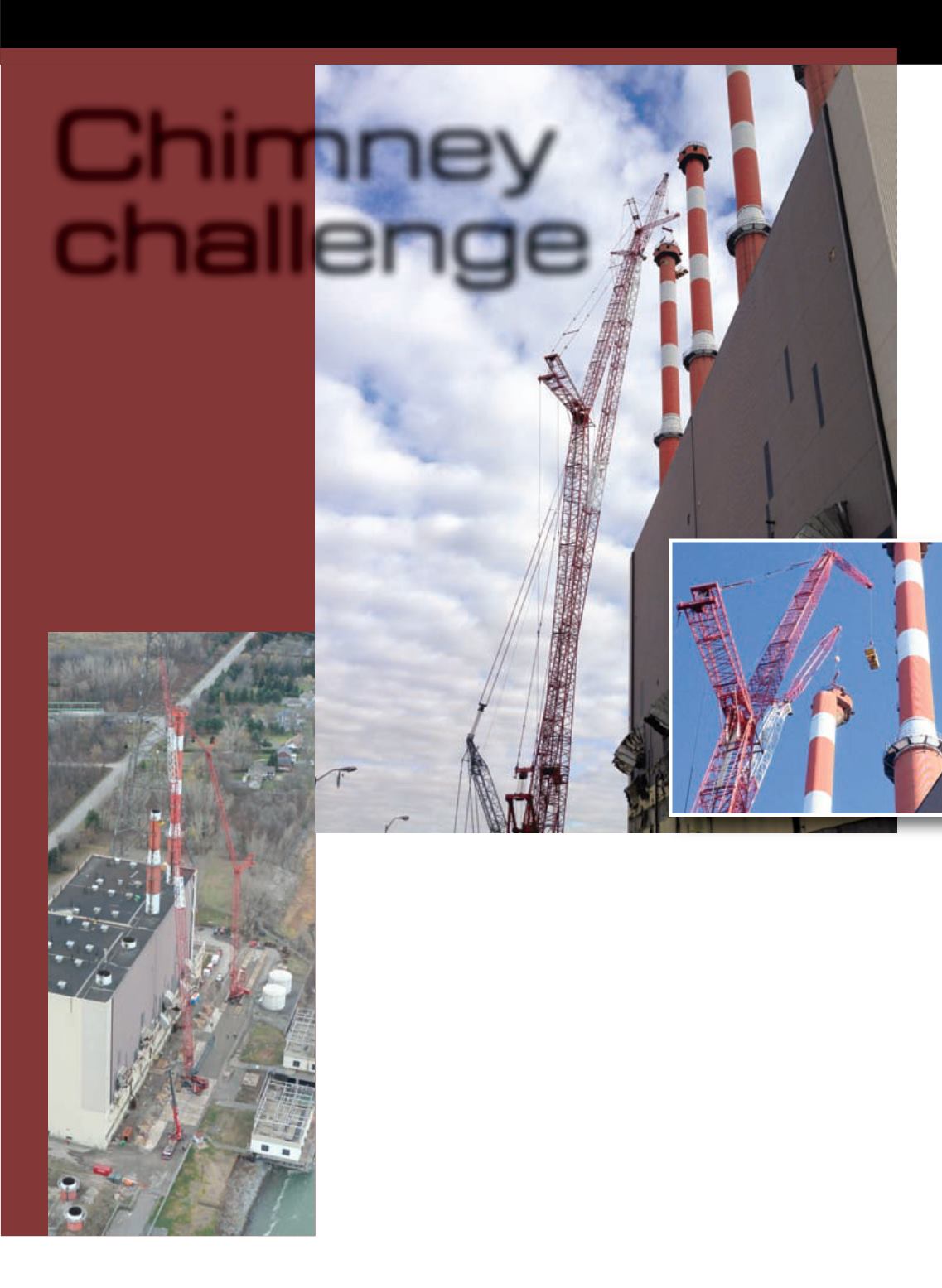

With two chimneys down and the

third one about half way dismantled,

crews had gotten the hang of the

tediouswork at height.