48

ACT

MAY 2014

SC&RA

JOBSOF THE YEAR

M

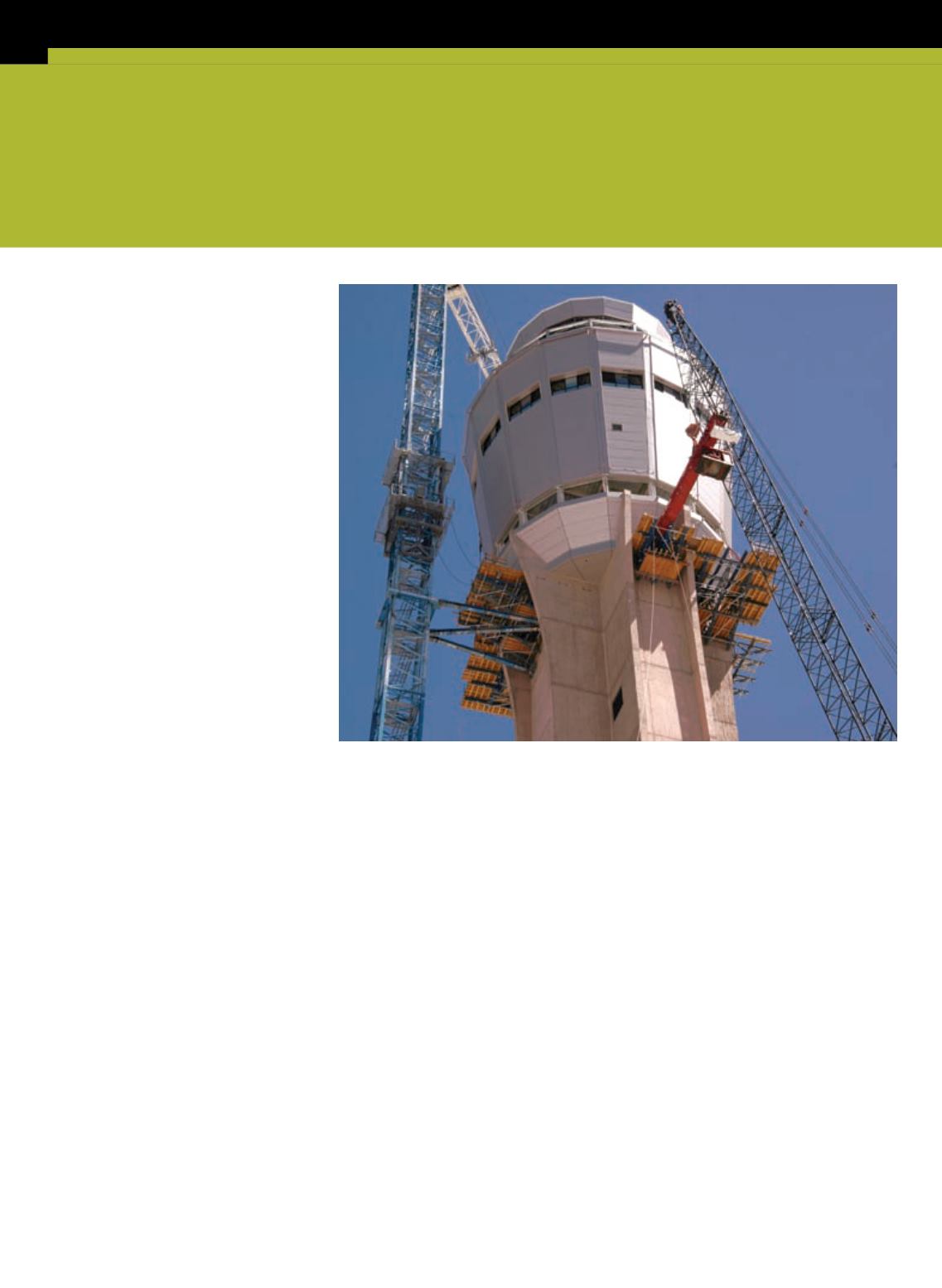

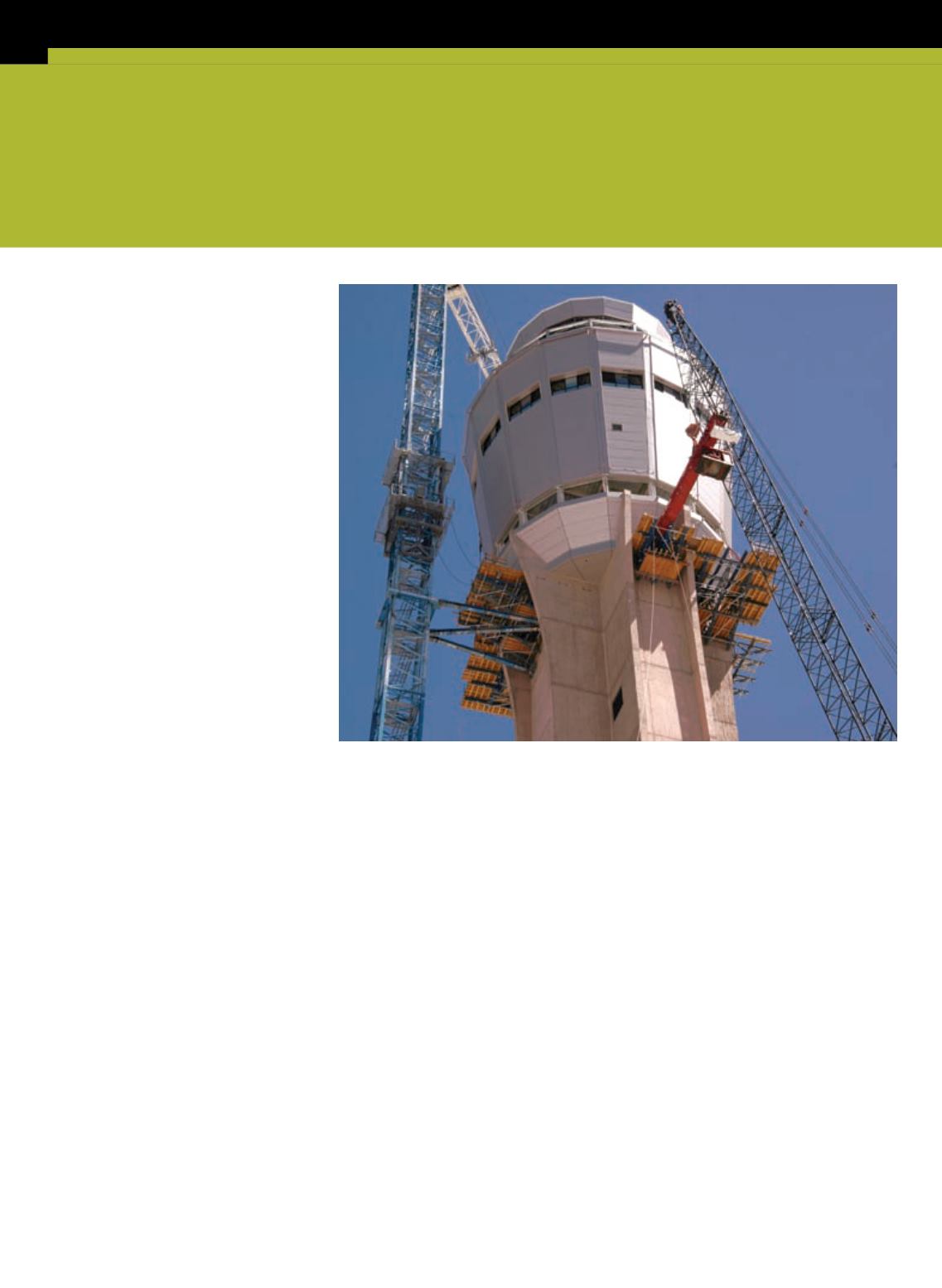

cCarran International

Airport inLasVegaswill

enjoy the completionof a

new352-foot tall control tower in2015.

InFebruary2013, the general contractor,

ArcherWestern, calledBarnhart tohelp

with removingplatforms that hadbeen

installed to construct the control tower

cabon topof the tower.

The 10platforms on the tower – each

measuring16 feet longby19 feetwide

by10 feet tall andweighing12,000

pounds –were 230 feet in the air.With

the control cab inplace, the tower crane

on theproject couldn’t remove the

platforms. Theoutermost diameter of the

caboverhung thewalls by18 feet. Itwas

impossible toget the tower cranehook

above the center of gravity (CG) of the

platforms.

Theoriginal plan to remove the

platformswas to setwinches on the

concrete floor slab above, run the line

through ahole in the floor, rig the line

to theplatform, and lower it to the

ground. But it didn’t account for thenew

architectural façade.

Barnhart presented the tip stick,which

was designed to tipobjects. In this

application, themainquestionwas how to

secure theplatform to the tip stick.Also,

wherewould thepump sit so that the

operator could run thepumpwhilebeing

able to see thepick?Another questionwas

how toprevent thehoses formhanging

230 feet in the air?To assurehosesweren’t

just dangling, Barnhart installed lifting

eyes on the control pump and rigged it

to the tip stick, allowing thepump to

function as a counterweight aswell. To

assure theoperator could see the tip stick,

a remote controlwith100 feet of cordwas

installed. This allowed theoperator to

grab the remoteoff of the endof the tip

stick and standon the adjacent platform,

wherehewouldbe able to safely see and

make thepick.

The tip stick’s control pump allows

thepick locationon thebeam tobe

manipulated. After the connection is

made theoperator slowlymoves the

pickpointmore towards the center of

workwas stopped ifwinds exceeded20

mph. Two300 foot taglines controlled the

movement of the tip stick to counter the

wind.

Theworkplan addressed crane setup,

boom tipheight, tip stickposition,

swingpath, landing zone, platform

connection, FAA coordination, access

to theplatforms, fall protection, fallen

worker rescue and removing the last two

platforms behind the tower crane.

Theprojectwas a true team effort. The

platform companyprovided engineering

to ensure that the connectionwas safe,

andDielcoCrane Serviceprovided

theoperatedLinkBeltHC278.Archer

Westernprovidedvaluable input to the

connection, their carpenters performed

thedeckmodifications and connections,

and they also coordinatedwithother

operations and theFAA.

All said anddone the jobwas completed

in less than fiveworkingdayswith a

crewof eight. Itwas performed aheadof

schedule, under budget andwithout any

safety incidents.

■

thebeam,which is thenewCGof the

loadwith theplatform attached. The lift

director could than lift theplatformoff of

the support bolts and fly theplatform to

the ground.

Fall protection planning

Riggingwas a challengebecause itwasn’t

possible toplace the tip stickdirectly

above theCG.Amoment-resistant hard

connection to theplatformswas designed,

allowing theplatform tobepicked even if

theCGwasn’t below thebeam.Aportion

of thedeckwas removed andbeamswere

installedover the topof the tip stick.

Fall protection and a strong

communications planwere important,

especiallyworking at 230 feet in the air.

The safetyplan called for crews to access

theplatforms using ladders from the

level above.Workerswere required to tie

off prior to exiting the control cabusing

50-foot retractable lanyards secured to

an engineered anchor point. The lifts

were timed to ensureplaneswerenot on

the adjacent taxiway.Windwas an issue;

RIGGINGUNDER $150,000

Tip stick solution

Barnhart

Barnhart used its tip stick

to remove construction

platforms from the new

tower being built at

McCarran International

Airport in Las Vegas.