42

ASSET TRACKING

IRN SEPTEMBER-OCTOBER 2013

One box solution

Danish asset tracking specialist Trackunit is

launching a new ‘single box’ asset management and

access control system that can be operated both

by an RFID card or PIN code. It’s the first PIN code

solutions offered by the company.

The 401 SmartID brings together access control

features and a GSM/GPS fleet management system

in a single box. It allows the operator access to the

machine by entering a unique PIN code or with a personal identification card. If personal identification cards

are preferred, it is possible to use existing company access cards

“The combination of PIN code identification and card identification in one, single solution is an innovation

in the field of access control,” says Jesper Rom Knudsen, head of direct sales at Trackunit. “It gives our

customers the opportunity to choose the exact user identification solution that matches their company and

their need for flexibility.”

One key benefit of the PIN functionality, says a company spokesman, is that “it really adds flexibility and

eliminates the need for a physical card. This makes it super quick for rental companies to send PIN-codes via

SMS to unlock machines at remote locations.” New users can be created easily and the system can handle an

indefinite number of PIN codes.

”By offering easy PIN code access, Trackunit

401 SmartID paves the way for new business

opportunities for rental companies, for example in

connection with large building or infrastructural

projects,” he says.

”Rental companies can set up unstaffed and

remote-controlled depots keeping a stock of

machines at large job sites and rent out equipment

at very short notice. If a contractor suddenly needs

a certain machine, the rental company can remotely

add a new user and text a PIN code that gives

immediate access to the machine in question.”

Universal SiteWatch kit that can be used with any

brand of machine, allowing rental customers with

mixed fleets to run a single fleet management

system.

Other manufacturers are already some way down

the road in terms of their telematic offerings. JCB’s

well-established LiveLink system, for example, is now

fitted as standard on 80% of its products sold across

Europe. Its 3CX and 4CX backhoe loaders, side-

engined Loadall telescopic handlers and tracked and

wheeled excavators are all fitted with LiveLink, as

are wheeled loaders above 8 t operating weight.

JCB also offers a scaled down version, LiveLink

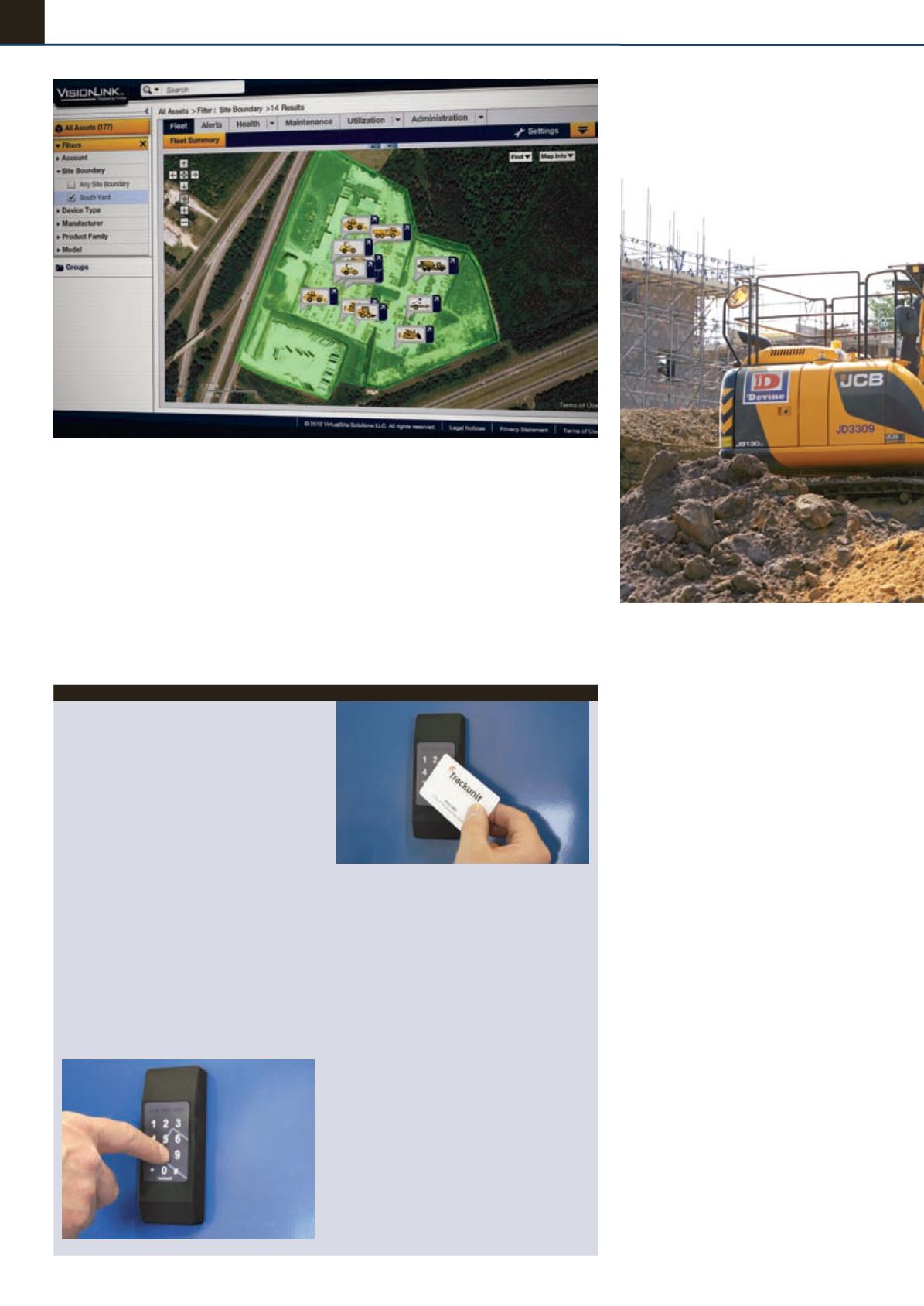

The VisionLink

web interface

for Caterpillar’s

telematics system

allows users to see

the site geofence.

JCB says that in its experience, it is large and

medium sized rental companies that have been the

greatest users of the system so far; “they are using

the system as a full fleet management tool that links

into their existing IT systems and can be used to

improve maintenance and customer support.

“For those with operated fleets and the larger

construction companies, benefits include the

understanding machine usage, fuel management

and monitoring of CO2. This is an increasing

requirement/need.”

The manufacturer says that for smaller companies

and owner operators, the benefits are more about

increased security and better support links to

dealers; “They can concentrate on running their

business and leave support to dealers knowing

that the dealer has greater visibility of usage and

understands what support the customer needs.”

JCB also makes the point that, with the introduction

of the latest Stage IIIB/Tier 4 Interim engines in

many machines, increased electronic technology has

made additional telematic functions possible. “These

include fuel economy data, including which working

mode the machine is operating in. This allows

managers to assess individual operators, checking

for extending idle time or poor use of eco modes

during general operation.”

Ambrose approval

One JCB customer, Richard Sykes, managing director

of Ambrose Plant Hire in the UK, backs this up;

“Increasingly, the customers we work with look for

hirers to provide more than just basic machines.

“With demanding service level agreements

it is essentially a fleet management and total

support solution that is required – ensuring the

best equipment is continually available at peak

performance - exactly where and when the customer

demands it.” It means that Ambrose can track its

Lite, for use on machines that don’t have it fitted

as standard, for example, on mini/midi excavators,

compaction equipment and other smaller machines.

As with the Case system, JCB says the system can be

fitted to other brands of machine (or retrofitted to

old JCB models.)

There is no separate cost for LiveLink and there

are no different ‘levels of service’, says JCB; “Once

you purchase a JCB machine with LiveLink fitted

as standard, you have complete access to all its

features. LiveLink costs are built into the machine.

So the customer effectively does not pay anything

extra for the solution.”

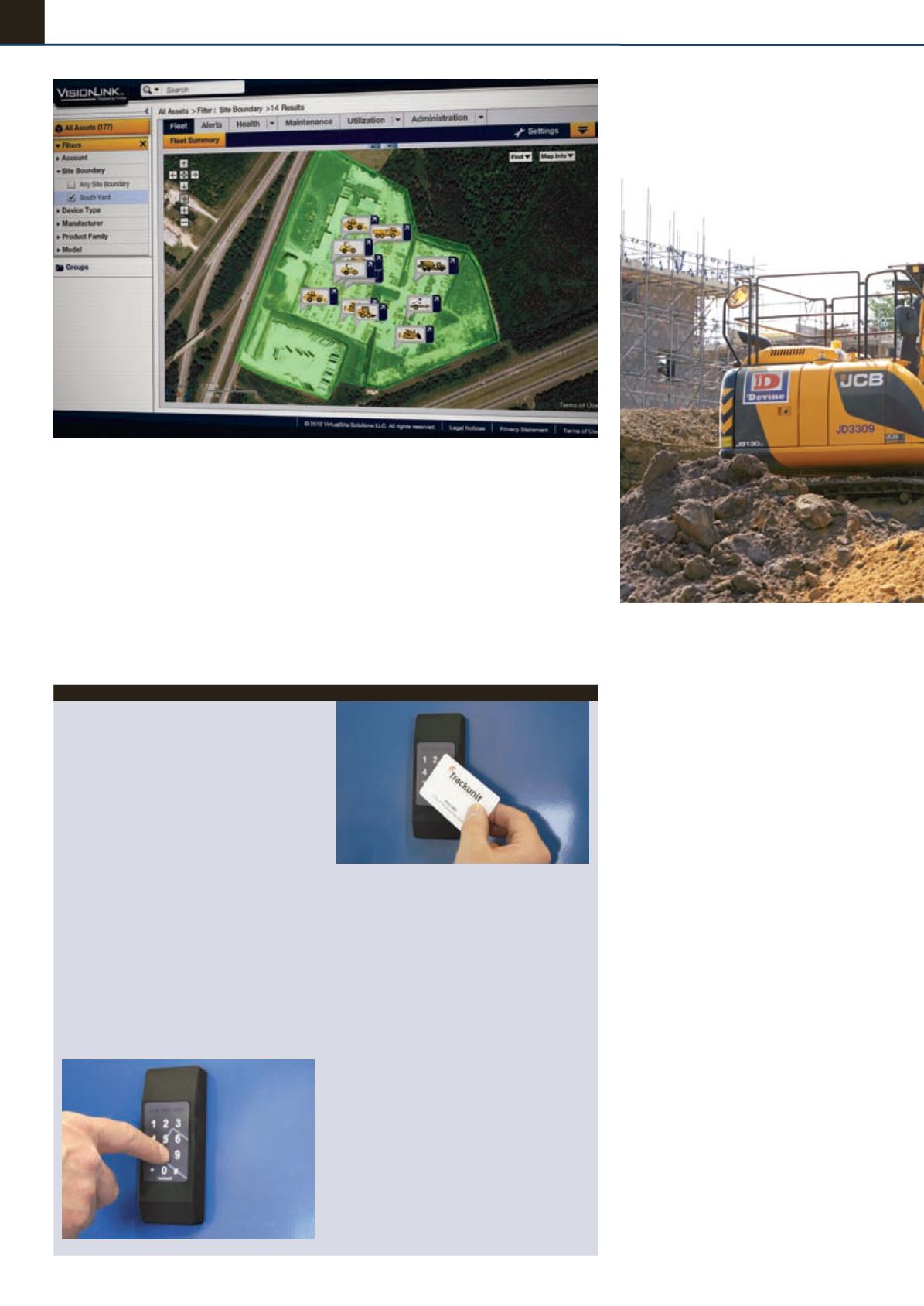

UK contractor and plant hirer J Devine Group recently bought

three JCB JS130 excavators, all fitted with the LiveLink

telematics fleet management system. Plant manager Tim

Brackley says; “With the click of a mouse I can send reports

to the board of directors who can assess the latest status and

ensure our investment is being maximised.”