35

november 2014

international

construction

ROADBUILDING

Project pressures

concreteoverlayaspart of the larger reconstructionof 12.5miles

(20.1km) ofHighway30.However,DarrLink’s resurfacingwas

scheduled in themiddle of harvest season, so consideration had

tobe given to the farmerswhose fields bordered it, aswell as the

daily traffic travelling between the twomajor highways.

In order to minimise disruption, Cozad-based contractor

Paulsenpaved its2.38km sectionof the job in twopasses, instead

of a single 7.6mwide pass whichwouldhave blocked the road.

It used a newGOMACO two-trackGP-2400 paver with Leica

Geosystems 3D guidance system. Although the company had

used Leica Geosystems 3D guidance system before on its GP-

2600paver, thiswas the first time for theGP-2400 and its crew.

Dave Neill, concrete paving assistant manager for Paulsen,

said, “When we purchased the system,

we hired two surveyors and they’ve

been a real advantage. Still, we were

pretty cautious on our first pour with

the stringless technology, but it’s pretty

straightforward. If you see the paver

heading towards the ditch, you know

something is wrong, shut it down.

Thankfully, that didn’t happen to us and

once we started using the systemwe saw

somany advantages.

“You don’t have to set any stringline

stakes, which takes a lot of time and

labour. You don’t have finishers hitting

a stringline and that all makes a big

difference.On this project, wherewe had

tomaintain traffic as we poured one lane

at a time, the biggest advantage was we

didn’t need the extra four feet (1.2m) of

offset for the stringline.”

Paving production on the overlay

averaged around 5,000 feet (1,524 m)

per day with very little finishing work

done behind the paver.The job used five

Leica total stations, set up at 300 foot

(91.4 m) intervals, which are more than

is strictly needed, but Paulson believes

the extra instruments help achieve a

higher production rate.

Earthmoving technology

And the use of the latest equipment can

also deliver benefits in the earthmoving

phase of road building, as illustrated

>

Drilling success

Key tips for concrete dowel drills

D

rilling into a concrete road slab to fit dowel barsmay sound like an easy task,

but there are several key steps that are crucial for efficiency, productivity and

safetywhen using specialised pneumatic drills, according to Randy Stevens,

vice president of sales at E-Z Drill.

AIR

- Each gang (drill) will require about 100 cfm (2.8m

3

/minute) of air, so be sure you

have a compressor with enough capacity.

DRILL BITS

- Install the drill bits using the right bit guide bushing and ensure the bit is

the right chuck size for the drill and the right length for the desired depth.

OIL

– Fill the oiler with rock drill oil. Other lubricants are too light and also contain

synthetics that can damage hoses and O-rings.

FEED PRESSURE

– Too high and rotationwill be slow or the drill may stop. Too low

and the drill will bounce off the concrete. Start around 18 to 25 psi (1.2 to 1.7 bar) for

horizontal drilling and 5 to 9 psi (0.3 to 0.6 bar) for vertical drilling. Each drill will need

separate adjustment onmulti-gang drills.

SAFETY

–Wear proper work attire including ear protection, safety glasses and

hardhats. Dust masks are critical and consider a dust collection or suppression kit for

your drill to reduce hazards associatedwith poor visibility. Drilling concrete creates a

lot of dust!

Compressed air can also cause serious injuries. Shut off the air supply and bleed the

line beforemoving or disconnecting air hoses or dissembling the drill.

Be aware of pinch points on the drills that can harm fingers, hands or limbs.

KEEP IT CLEAN

– A concrete drill accumulates a lot of dust, so at the end of each

workday use your air compressor to blow it off. Regularly cleaning your drill will prevent

clogging and excessive dust build-up. If it rains, any dust that has accumulated on a

drill that hasn’t been cleanedwill quickly harden to concretewhen it dries, which can

be very hard to remove.

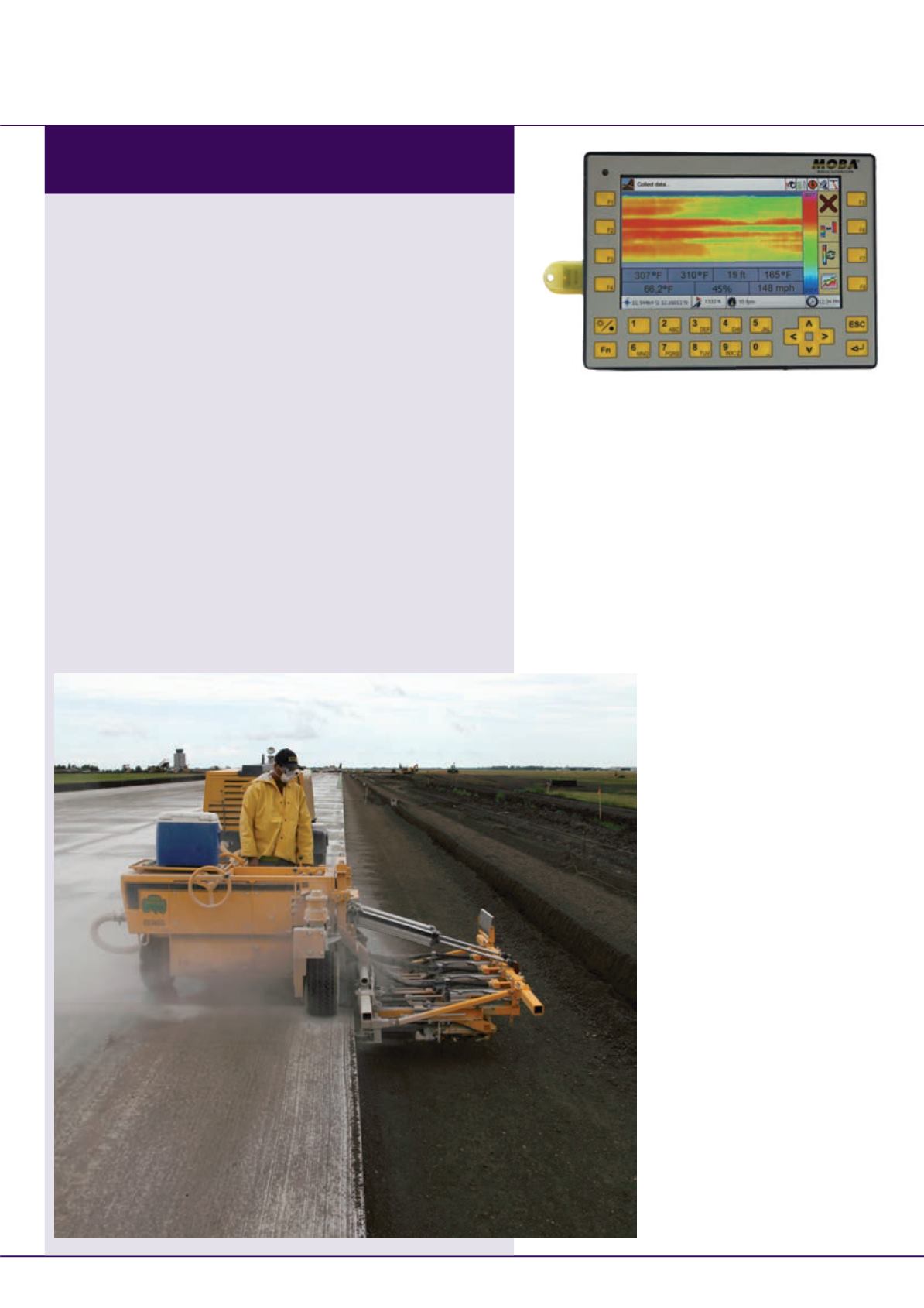

Systems such asMoba’s Pave-IRmodule can be used to log

and document asphalt temperatures as thematerial is laid.