international

construction

november 2014

LARGESTRUCTURES

40

Scaling new heights

Hong Kong heights

Three Liebherrs build observationwheel

T

hree Liebherrmobile cranes, includingHongKong’s first 400 tonne Liebherr LTM

1400-7.1 owned by rental company SetWinHeavy Lift, are performing key lifting

duties to raise a 60m high observationwheel on the central waterfront.

As part of thework, the new cranewas initially used to raise and hold in position the two

pre-assembled twin 36m longmain supporting legs and the central hub of thewheel, with a

combinedweight ofmore than 65 tonnes, positioned and held at an angle of 45°.

Additional Liebherr 100 tonne and 200 tonnemobile craneswere then used for the project

in tandem lifts to position the two remaining support legs, eachweighing 27 tonnes and

connecting to the central hub.

directly beneath the RiverThames to link-up with the existing

undergroundnetwork, theUK£200million (US$320million)

NorthWoolwich tunnel has encountered a number of technical

challenges during its construction.

With some 300 construction staff on-

site at any one time, the joint venture

between Hochtief and Murphy spans

2.5 km in length.

This required the efforts of two 7.1 m

diameter Herrenknecht tunnel boring

machines (TBMs) operated by crews of

20 workers on shift-patterns 24-7 for

nearly 18months fromMay 2012.

ProjectmanagerNeilMurray explained

that delivering it safely on time and on

budget were the key elements to the

scheme, describing completion of the

tunnellingwork as a “keymilestone.”

He said, “We aredelightedwith theway

the two tunnel portals have been formed

at North Woolwich and Plumstead.

We’re also extremely pleased with the

tunnelling – they are finished to a very

high quality and it has been done safely.”

The issue of following strict health and

safety guidelines has been of particular importance. Everything

frommaintaining an exact log detailing howmany people are

working below and above ground at any one time, to ensuring

construction workers are equipped with advanced breathing

apparatus in the event of a gas leak.

In terms of the tunnelling itself, the TBMs– known as

Sophia andMary (named after 19

th

century engineer Isambard

Kingdom Brunel’s wife and mother), have been built to cope

with the testing geological conditions below theRiverThames.

Clearly, using such immense machines requires considerable

expertise.What were the biggest challenges?

The project manager added, “The ground strata varied

dependingon thedepth and location - combinationof sand and

gravels and as we got deeper, we entered chalk – when you go

from one sub-strata to the next, that’s where the trickiest part

of the operation is, but we tackled this head on and we were

successful getting through each layer to the finish.”

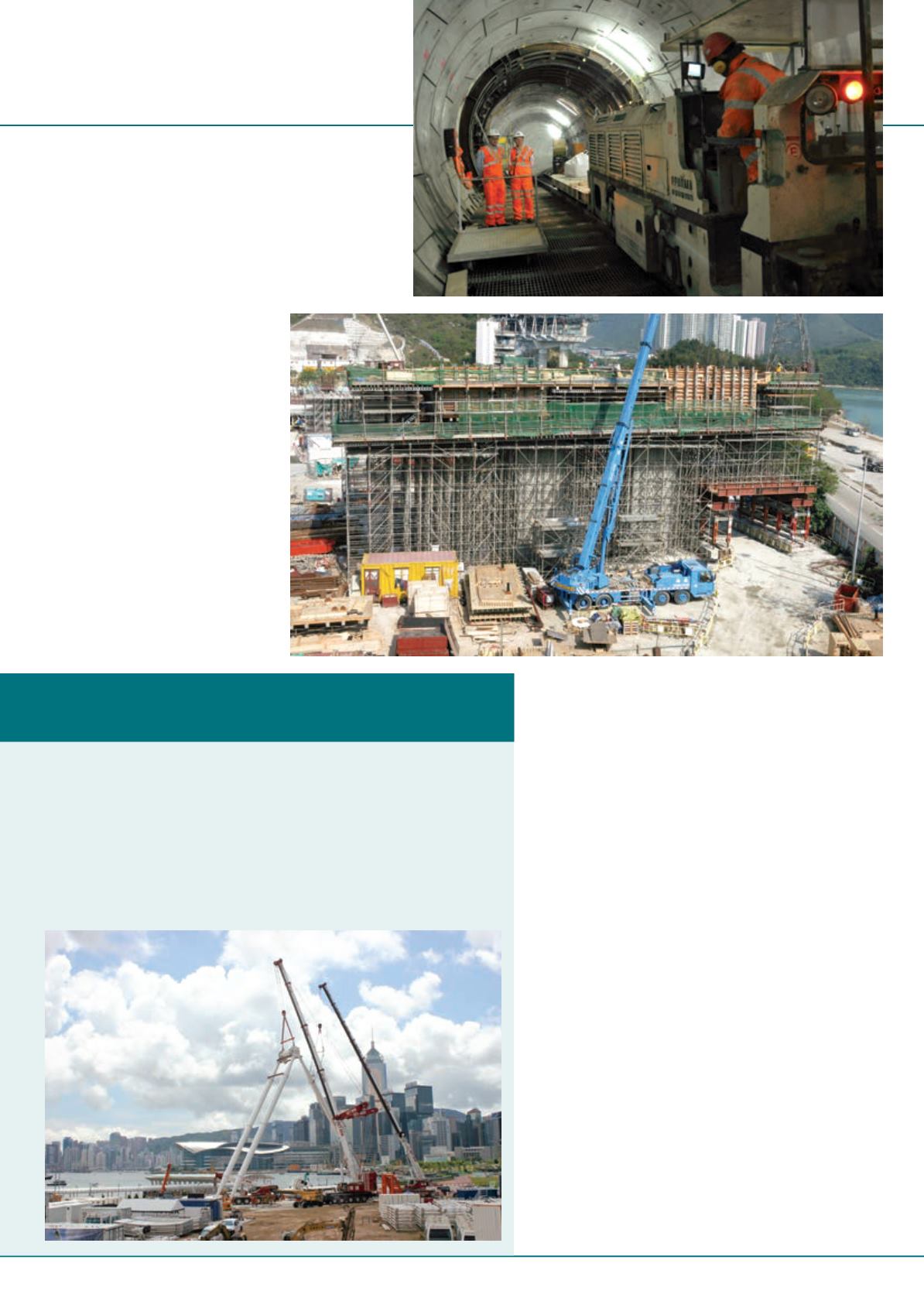

HongKong

One region that has seen a particularly steep level of growth for

major construction projects has beenHongKong.

As Noel Kennedy, country director of RMD Kwikform,

enthused, the expansion of the construction sector had

prompted the company to review its strategies and approaches

to itsmajor projects.

These include the Kowloon rail terminus and the UK£ 6.5

billion (US$ 10.47 billion) Hong Kong - Zhuhai - Macau

Bridge, whichwas first mooted in the early 1980s and is finally

coming to fruition.

It will include a 12 km link road, boundary crossing facilities

for government officials and their respective departments, in

addition to further infrastructure development.

At 29 km in length, the bridge is one of the largest schemes

>

The Crossrail scheme in London is presently Europe’s largest

construction site. It includes a UK£ 200million(US$ 322

million) tunnel under the Thames at NorthWoolwich.

The Hong Kong – Zhuhai –Macau Bridge.