31

november 2014

international

construction

ROADBUILDING

Project pressures

front, emulsion tanker truck, Roadtec RX-900e cold planer,

Roadtec RT-500mobile recycle trailer, a Caterpillar paver and

Caterpillar tandem and rubber-tyred rollers.

The RT-500 functioned like a material transfer vehicle,

providing a steady flow of recycled asphalt pavement (RAP)

to the paver allowing for continuous, steady production runs,

which resulted in smooth a pavement.

BR-381 is constructed with fine grain hard granite aggregate,

whichwas a challenge tomill.The contractor usedKennametal

teeth, whichwere replaced every two to three days of operation.

Themill typically cut 4.33-inches (110mm) deep and averaged

forward progress of 30 fpm (9m\min).

The emulsionpercentagewas adjusted from2.8% to3.5% and

the water was adjusted from 1.8% to 3.5% during operation.

However, the contractor added that on hot days the water

requirements could go as high as 4%.

BrownBrownmodified the paver hopper to add capacity and

installed sloped diverters to help prevent material build-up in

the corners. The hopper was also kept full to add weight and

improve the stability of the screed.

“The advantage of this style of CIRplant is thatmaterial from

the mill is directly deposited into the paver which appears to

help generate an improved surface finishon the newpavement,”

concludedMike Fischer, Roadtec field service technician.

New approach

And in-situ recycling is a concept that can also be applied to

reconstruction of deeper layers of highways. For example,

contractorNyoni Projects is taking a new approach to two road

upgrades in the NorthWest province of South Africa with the

use of two newCat RM300RotaryMixers.

“On both projects, we’ve noticed that the use of the RM300s

enhanced the speedatwhich layerswereprocessedandfinalised,”

said Nyoni Projects managing director, Maclaud Nyoni. “We

can do a 300 mm thick layer in one

operation, yet with graders we could

only do a 150 mm layer at a time. The

production levels from the RM300more

than trebledwhat one could achievewith

a grader team, yet manpower resources

remained the same, and other support

(water trucks) only doubled.”

The North West roads work is the

largest ever for Nyoni Projects. The

first North West section involves the

>

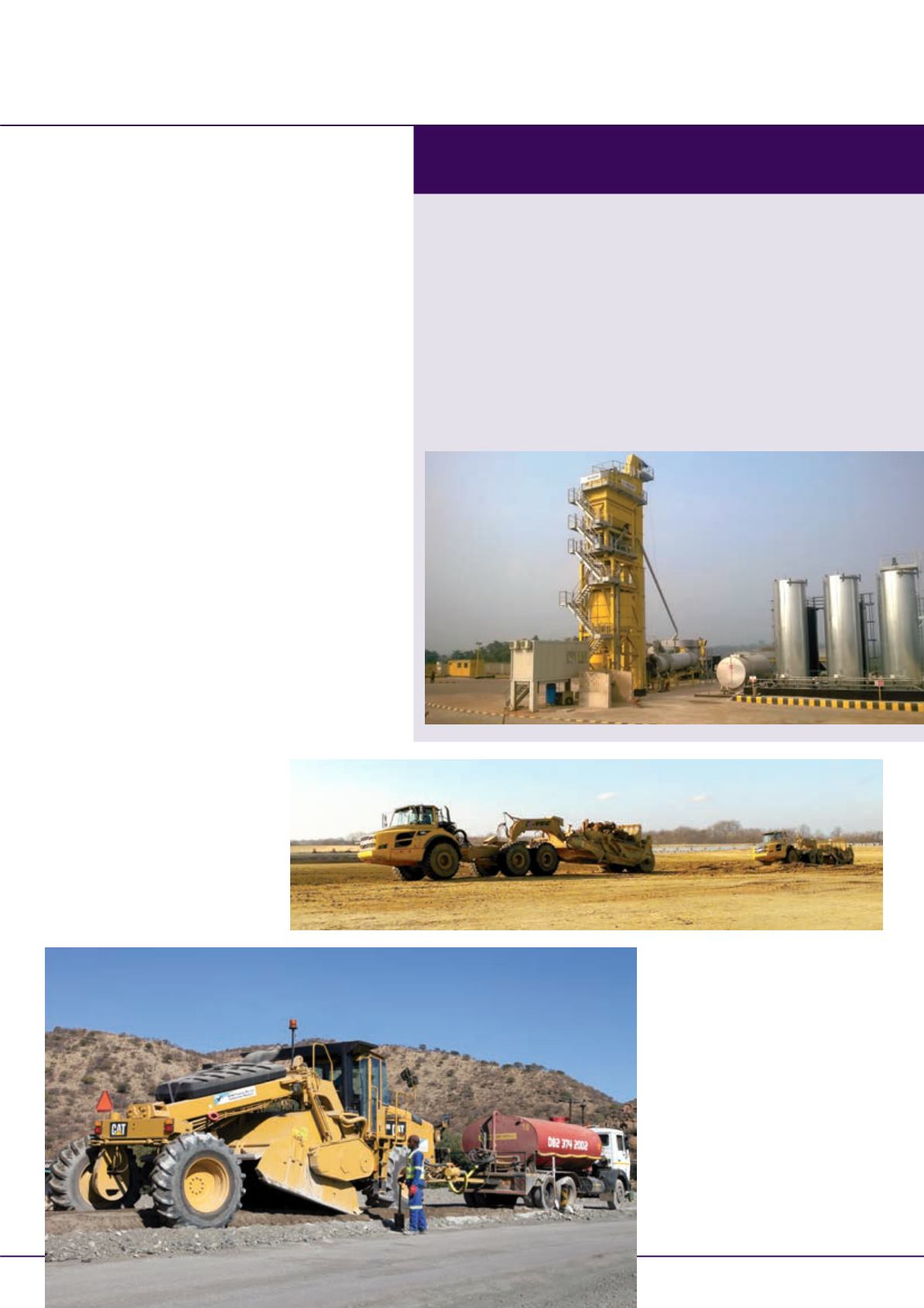

Lagos plant

Demanding requirements pointed toMarini UltiMAP 2000

I

n 2010 a five year planwas put in place to improve roads in and around the Nigerian

capital, Lagos. To help achieve this, a 180 tonne/hour asphalt plant was commissioned

in the suburb of Imota.

A key requirement was that the plant would be able to handle large amounts of recycled

asphalt pavement (RAP) and this dictated the decision to pre-treat thematerial in order to

control the quality of old bitumen and the size of recovered aggregates.

Accuratemetering of materials, flexible production (including the ability to produce small

batches), flexibility and frequent changes of mix (including coloured and fibre-enhanced

mixes) were also all requirements alongwith the need for efficiency and high production

standards.

This all led to the choice of aMarini UltiMAP 2000 in 2013 as the asphalt plant. Among

other key features, the unit offers 300 tonnes of bitumen storage in six tanks, allowing the

use of different blends.

ABOVE: Bloomsdale Excavating is using

13 Volvo full suspension A40F haulers

with K-Tec scrapers tomove 2.5million

m

3

of earth on a road building project in

Illinois, US.

LEFT: Nyoni Projects is using

Caterpillar RM300 rotarymixers to

speed up twomajor road rehabilitation

projects in South Africa.